Processing technology of green tea

A processing technology and technology for green tea, applied in the directions of tea, tea spice, tea treatment before extraction, etc., can solve the problem of green tea being bitter and astringent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

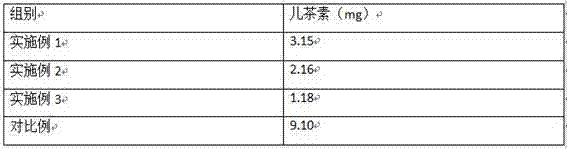

Examples

Embodiment 1

[0016] Embodiment 1: a kind of processing technology of green tea, comprises the following steps:

[0017] Step 1. Green spreading: Pick fresh leaves with one bud and one leaf or one bud and two leaves on the Zicuckoo tea tree, and spread the fresh leaves on bamboo rafts. The thickness of the spreading is 4cm, and the spreading time is 3 hours. Turn the tea leaves every 1 hour;

[0018] Step 2. Finishing: put the green tea leaves into the greening machine for finishing, the temperature for finishing is 300°C, and the finishing time is 10 minutes;

[0019] Step 3. Kneading: Select 3 parts of fresh and tender cucumber and 10 parts of Camellia oleifera tea slices with thick and white pulp, wash and mix, squeeze the juice, filter to get the juice, then add 5 parts of brown sugar water and stir evenly to form a mixed juice , put the green leaves obtained after finishing into a kneading machine and knead them into strips, spray the mixed juice on the surface of the tea leaves durin...

Embodiment 2

[0023] Embodiment 2: a kind of processing technology of green tea, comprises the following steps:

[0024] Step 1. Green spreading: Pick fresh leaves with one bud and one leaf or one bud and two leaves on the Zicuckoo tea tree, and spread the fresh leaves on bamboo rafts. The thickness of the spreading is 5cm, and the spreading time is 3.5 hours. Turn the tea leaves every 1.2 hours;

[0025] Step 2. Finishing: Put the green tea after spreading into the greening machine to finish. The finishing temperature is 320°C, and the finishing time is 13 minutes;

[0026] Step 3. Kneading: Select 4 parts of fresh and tender cucumber and 13 parts of Camellia oleifera tea slices with thick and white flesh, wash and mix, squeeze the juice, filter to get the juice, then add 6 parts of brown sugar water and stir evenly to form a mixed juice , put the green leaves obtained after finishing into a kneading machine and knead them into strips, spray the mixed juice on the surface of the tea leave...

Embodiment 3

[0030] Embodiment 3: a kind of processing technology of green tea, comprises the following steps:

[0031] Step 1. Green spreading: Pick fresh leaves with one bud and one leaf or one bud and two leaves on the Zicuckoo tea tree, and spread the fresh leaves on bamboo rafts. The thickness of the spreading is 6cm, and the spreading time is 4 hours. Turn the tea leaves every 1.5 hours;

[0032] Step 2. Finishing: put the green tea leaves into the greening machine for finishing, the temperature for finishing is 330°C, and the finishing time is 15 minutes;

[0033] Step 3. Kneading: Select 5 parts of fresh and tender cucumber and 15 parts of Camellia oleifera tea slices with thick and white pulp, wash and mix, squeeze the juice, filter to obtain the juice, then add 8 parts of brown sugar water and stir evenly to form a mixed juice , put the green leaves obtained after finishing into a kneading machine and knead them into strips, spray the mixed juice on the surface of the tea leaves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com