An energy-saving metal strip rolling mill and rolling method

An energy-saving technology for metal strips, applied in the direction of metal rolling, metal rolling, and driving devices for metal rolling mills, can solve the problems of small cumulative reduction rate in a single rolling process, high unit energy consumption, and thinning capacity. Limited and other problems, to achieve the effect of reducing the number of rolling passes and intermediate annealing times, the cumulative reduction rate is large, and the reduction amount of each pass is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

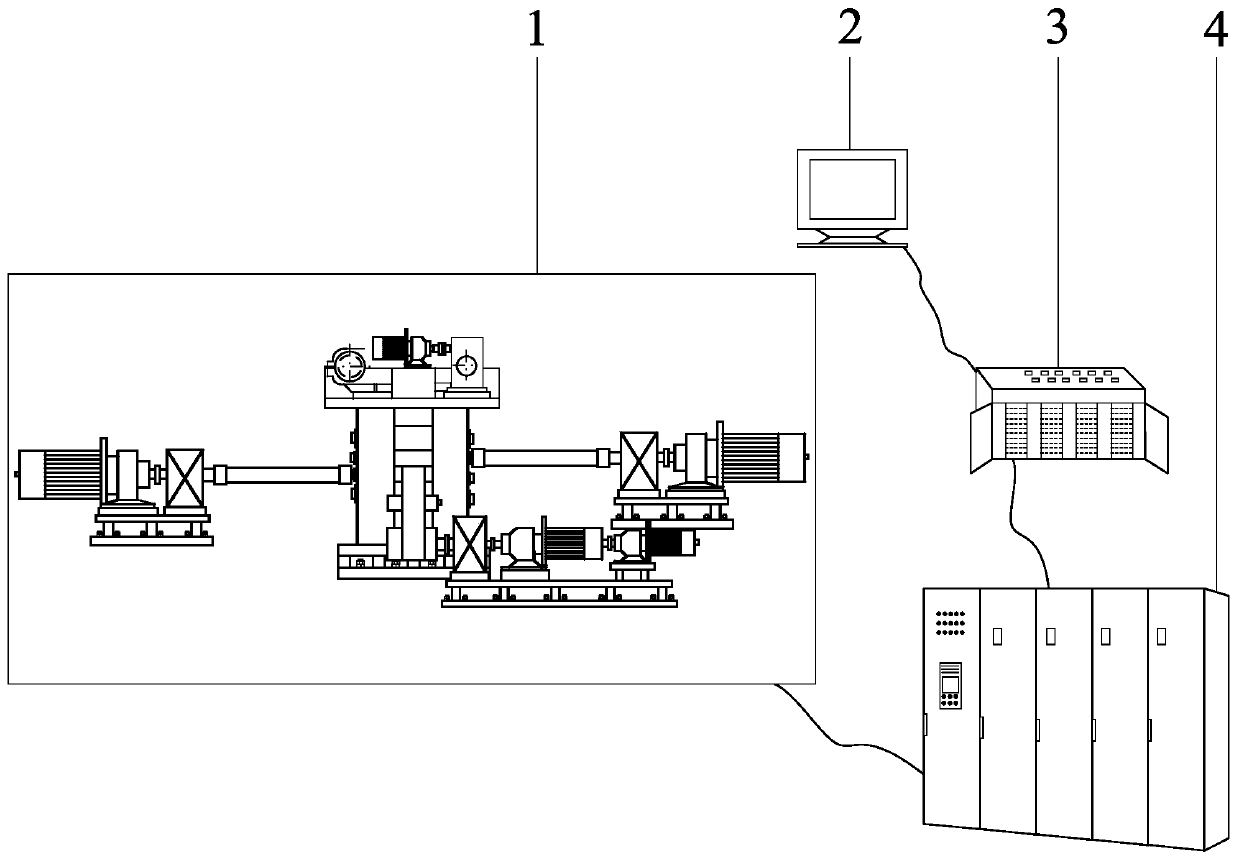

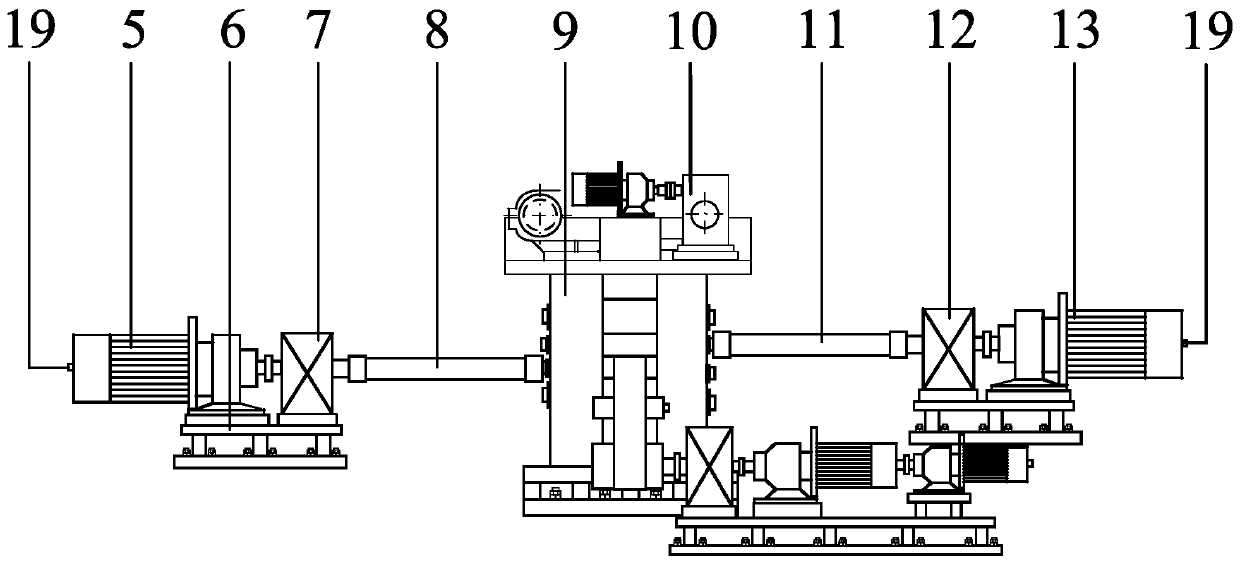

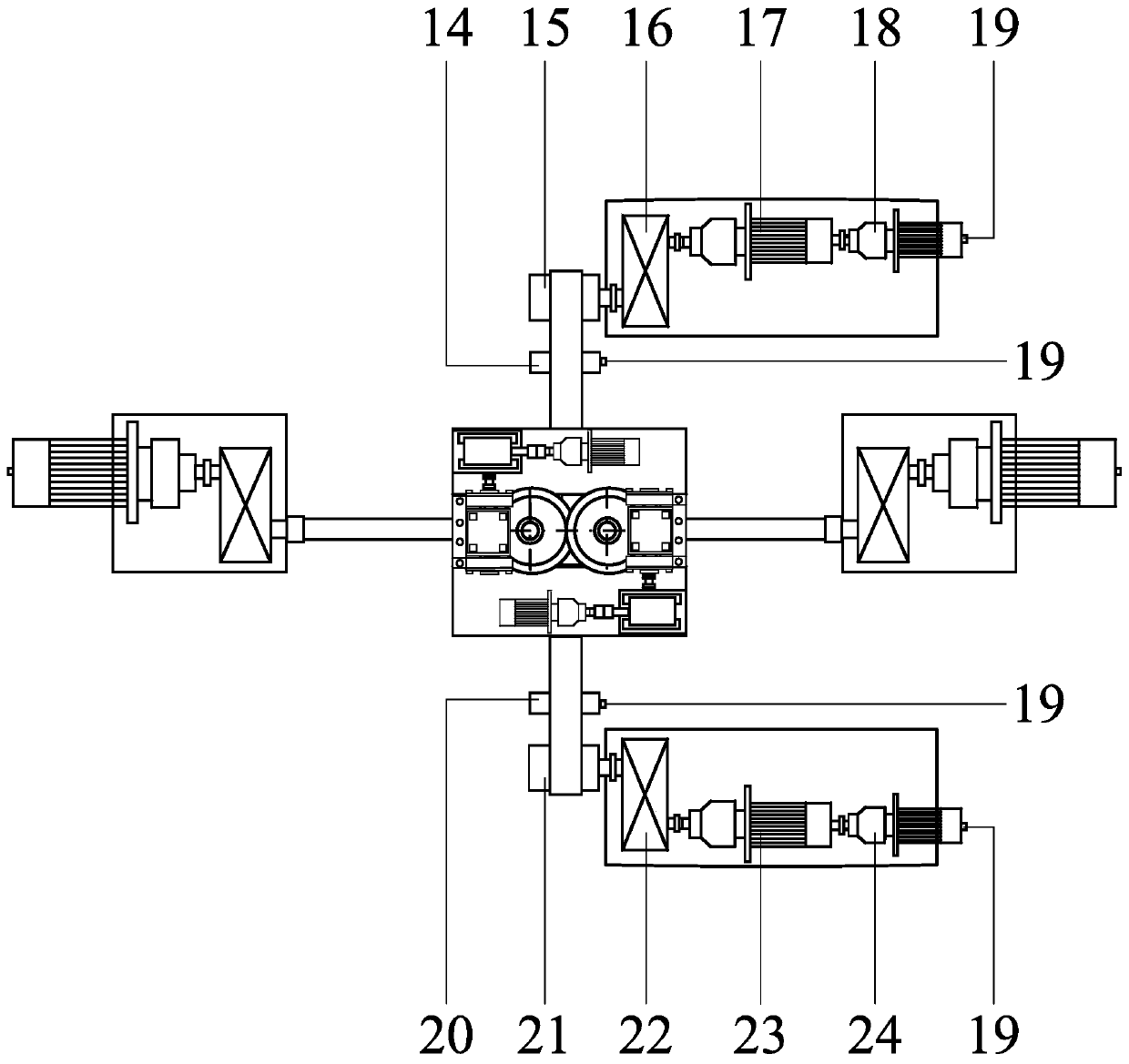

[0044] In this embodiment, the structural diagram of the rolling mill is shown in figure 1 , the structural diagram of the mechanical part of the rolling mill is shown in figure 2 , image 3 , Figure 4 with Figure 5 , see the content of the invention for the specific structure. Both the main drive motor and the take-up motor use 4-fold frequency motors, and the coiling and rewinding adopt the form of double take-up motors in series, and the main drive motor and the take-up motor are driven by a common DC bus multi-machine drive four-quadrant inverter. The coiling tension is divided into three gears, the range of the high tension gear is 50-80kN, the middle tension gear is 20-50kN, and the small tension gear is 3-20kN. The rolled piece is 304 stainless steel, the initial thickness of the rolled piece is 1.0mm, the width is 450m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com