High energy-saving hot-pressing type distilled water machine

A technology of distilled water machine and distilled water, applied in heating water/sewage treatment and other directions, can solve the problems of increased pure steam flow resistance, reduced working efficiency of hot press, waste of energy, etc., to reduce resistance and heat dissipation loss energy, increase Effective heat transfer temperature difference and the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

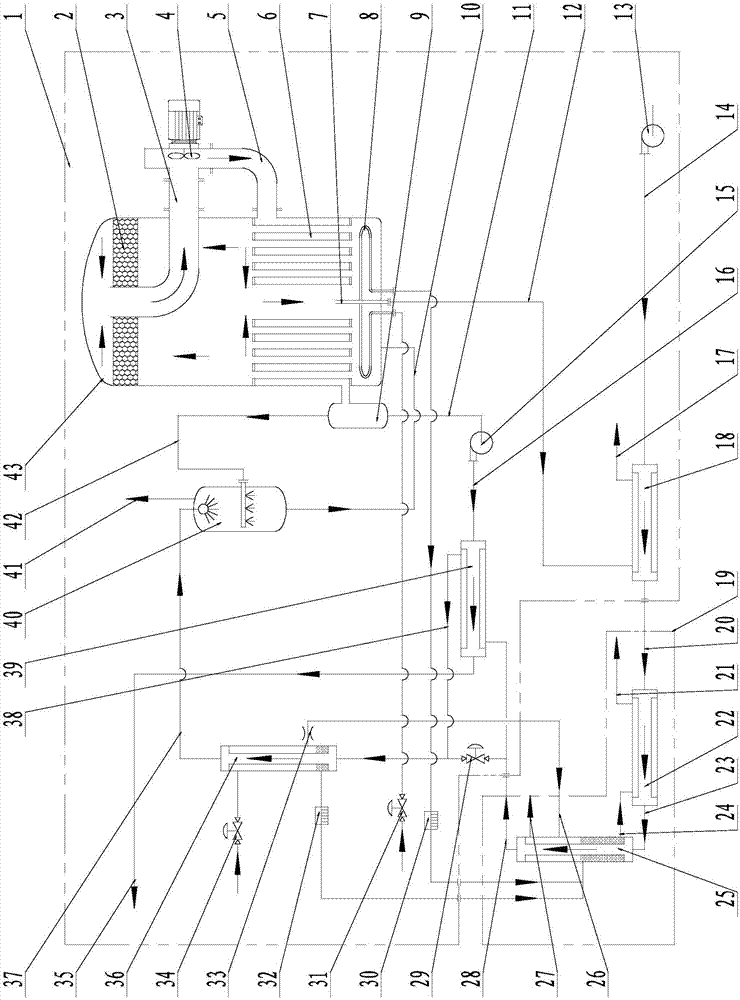

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

[0040] This embodiment is a high-energy-saving vertical hot-pressed distilled water machine, which is composed of a vertical hot-pressed distilled water production device 1 and a working steam condensate heat recovery device 19 .

[0041] The vertical hot-pressed distilled water production device 1 is composed of a raw water inlet system, an evaporation system, a raw water heating system, a distilled water temperature adjustment system and a non-condensable gas separation system; the working steam condensate heat recovery device 19 is composed of a working steam condensate The water heat primary recoverer 25 and the working steam condensation heat secondary recoverer 22 constitute.

[0042] The working steam condensate heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com