Integrated recycling-type biological sewage treatment device and correlation method thereof

A kind of sewage treatment equipment and circulation technology, applied in biological water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as high operating cost, hidden dangers of operation management safety, unstable operation, etc. , to achieve the effect of safe and reliable operation, convenient maintenance and management, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

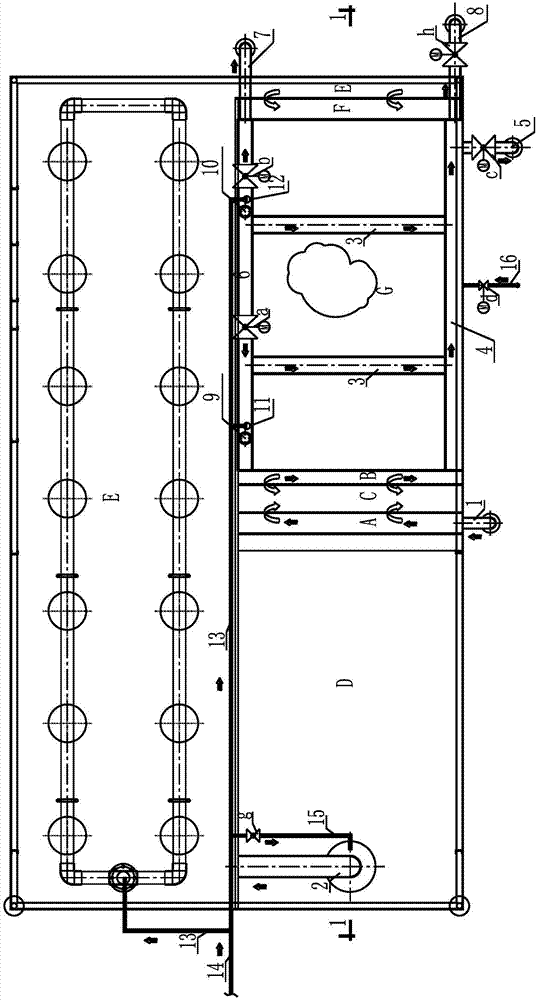

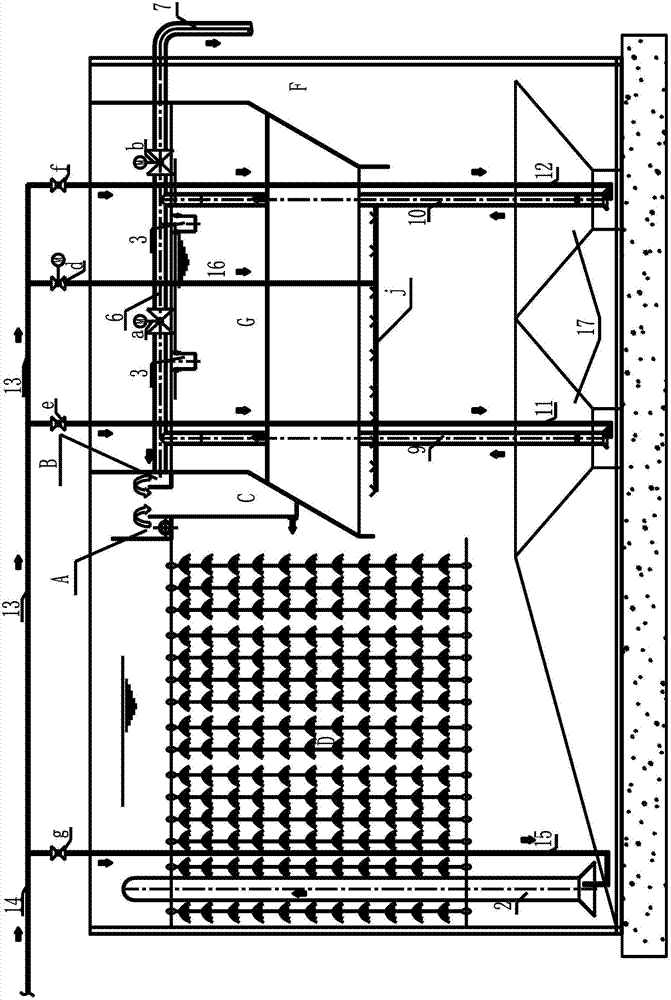

[0038] In a nutshell, the present invention is a sewage biochemical treatment process (including activated sludge method, contact oxidation method or activated sludge method and contact oxidation method combined sewage biochemical treatment process) and precipitation (the form of precipitation can be determined according to the target water quality of the effluent. It is required to use flat flow sedimentation, vertical flow sedimentation, inclined tube sedimentation and contact sedimentation, etc.) to form an integrated sewage treatment equipment similar to an oxidation ditch. At the same time, the principle of air lift is used to drive the sewage flow in the integrated sewage treatment equipment. For backflow and sludge discharge, air lift is used to replace traditional mechanical backflow such as pumps or submersible flowmakers, which is especially suitable for small integrated sewage treatment devices. The sewage treatment equipment is made of corrosion-resistant materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com