A double anti-counterfeiting inkjet printing ink

An ink and dual technology, applied in the field of dual anti-counterfeiting inkjet printing ink, can solve the problems of ambiguous identification information, unfavorable and effective reading of identification information, affecting product information monitoring or traceability, etc., to achieve the effect of increasing recognizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

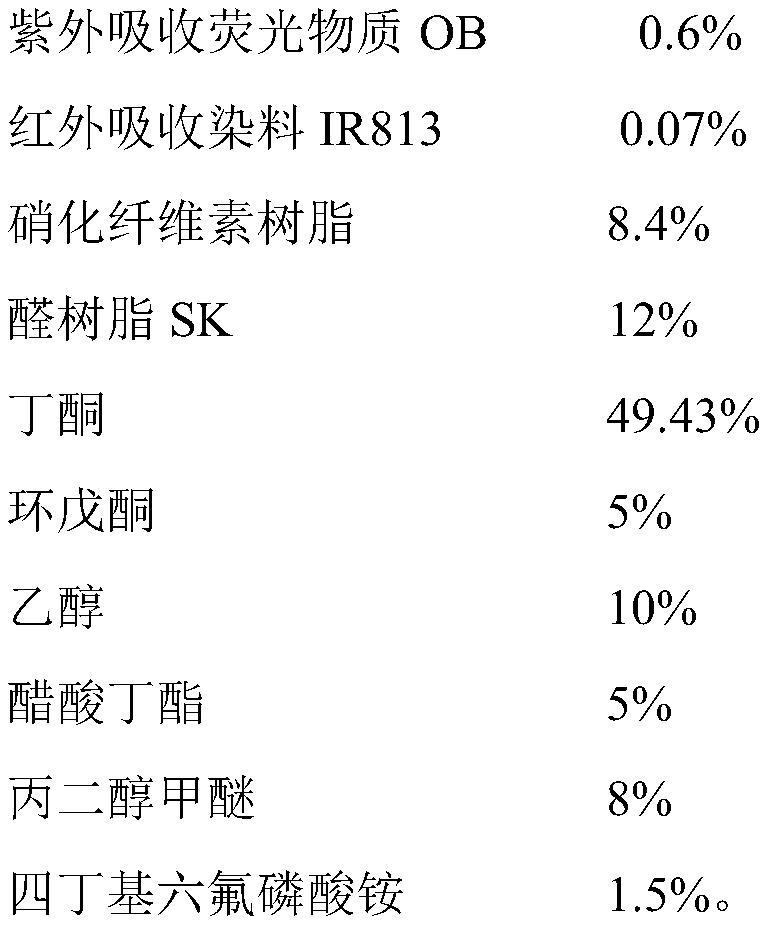

Embodiment 1

[0035] This embodiment provides a double anti-counterfeiting inkjet printing ink, in weight percentage, the inkjet printing ink has the following composition:

[0036] Material A: butanone 49.43%, cyclopentanone 5%, butyl acetate 5%, propylene glycol methyl ether 8%, aldehyde resin SK 12%, nitrocellulose resin 8.4%, ultraviolet absorption fluorescent substance OB 0.6%, tetrabutyl Ammonium hexafluorophosphate 1.5%;

[0037] Material B: ethanol 10%, infrared absorbing dye IR813 0.07%;

[0038] The sum of the percentages of each component is 100%.

[0039] The solid content of the double anti-counterfeit jet printing ink is 22%, and the viscosity at 25° C. is 4.2 cp.

[0040] The double anti-counterfeiting inkjet printing ink is prepared according to the following steps: sequentially dissolve tetrabutylammonium hexafluorophosphate, aldehyde resin SK, nitrocellulose resin and ultraviolet-absorbing fluorescent substance OB with the solvent in material A;

[0041]Heat the ethanol...

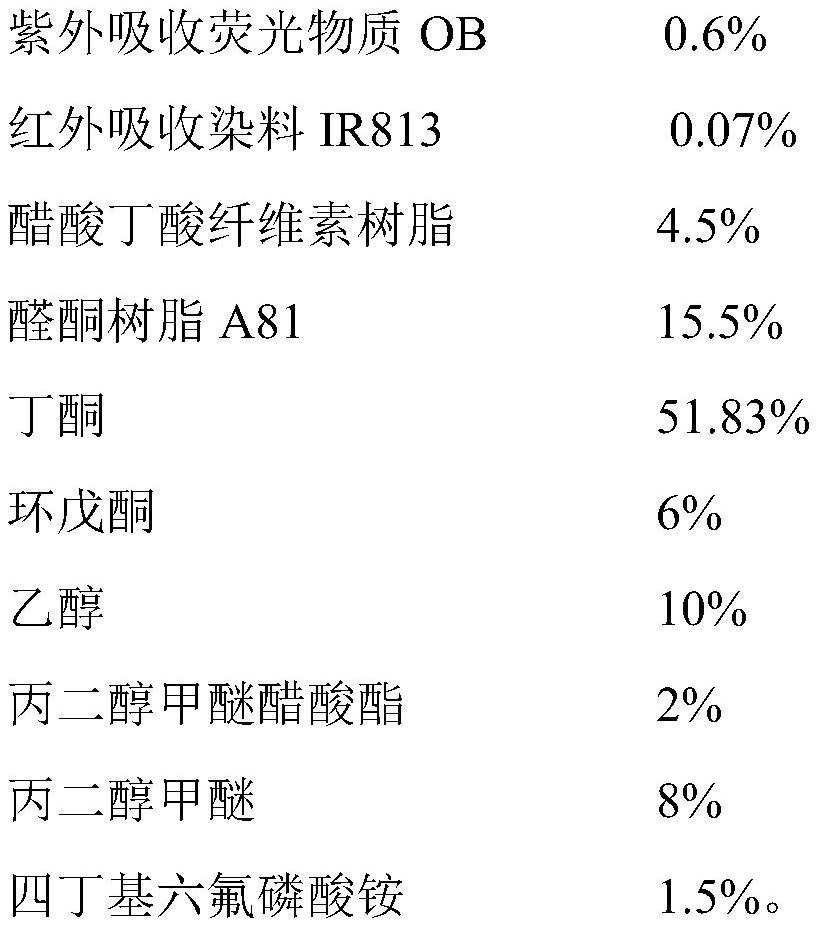

Embodiment 2

[0044] This embodiment provides a double anti-counterfeiting inkjet printing ink, in weight percentage, the inkjet printing ink has the following composition:

[0045] Material A: butanone 51.83%, cyclopentanone 6%, propylene glycol methyl ether acetate 2%, propylene glycol methyl ether 8%, aldehyde and ketone resin A81 15.5%, cellulose acetate butyrate resin 4.5%, ultraviolet absorption fluorescent substance OB 0.6 %, tetrabutylammonium hexafluorophosphate 1.5%;

[0046] Material B: ethanol 10%, infrared absorbing dye IR813 0.07%;

[0047] The sum of the percentages of each component is 100%.

[0048] The solid content of the double anti-counterfeit jet printing ink is 22.17%, and the viscosity at 25° C. is 4.2 cp.

[0049] The double anti-counterfeit jet printing ink is prepared according to the following steps: sequentially dissolve tetrabutylammonium hexafluorophosphate, aldehyde and ketone resin A81, cellulose acetate butyrate resin and ultraviolet-absorbing fluorescent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com