High-grammage coated paper bonding weather-proofing sealant

A technology of coated paper and weather-resistant glue, applied in the direction of adhesive, wax adhesive, adhesive type, etc., can solve the problems of slow curing speed, poor initial adhesion effect, poor flexibility, etc., and achieve fast curing speed and good fluidity. , the effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0017] Example.

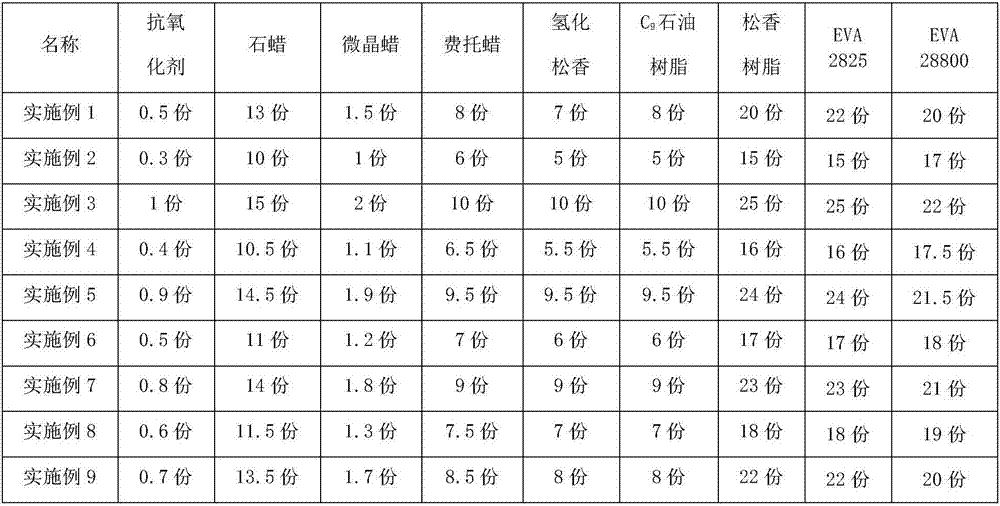

[0018] The high-gram coated paper bonding weather-resistant adhesive in this embodiment includes the following components: antioxidant, paraffin, microcrystalline wax for increasing the bonding range and low-temperature resistance, and Fischer-Tropsch wax for enhancing aging resistance Hydrogenated rosin, C for enhanced weather resistance 9 Petroleum resin, rosin resin for enhancing initial tack performance, for increasing cohesive strength and glue hardness and improving formability EVA2825 with a melt index of 25 and a VA content of 28 for increasing cohesive strength and glue hardness EVA28800 with a melt index of 800 and a VA content of 28 improves moldability.

[0019]

[0020] The parts mentioned in the above table are all p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com