Composite material for ecological restoration as well as preparation method and application thereof

A composite material and ecological restoration technology, applied in the fields of application, soil conditioning materials, chemical instruments and methods, etc., can solve problems such as reducing available land resources, achieve good air permeability and water holding capacity, easy to obtain raw materials, and remarkable effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

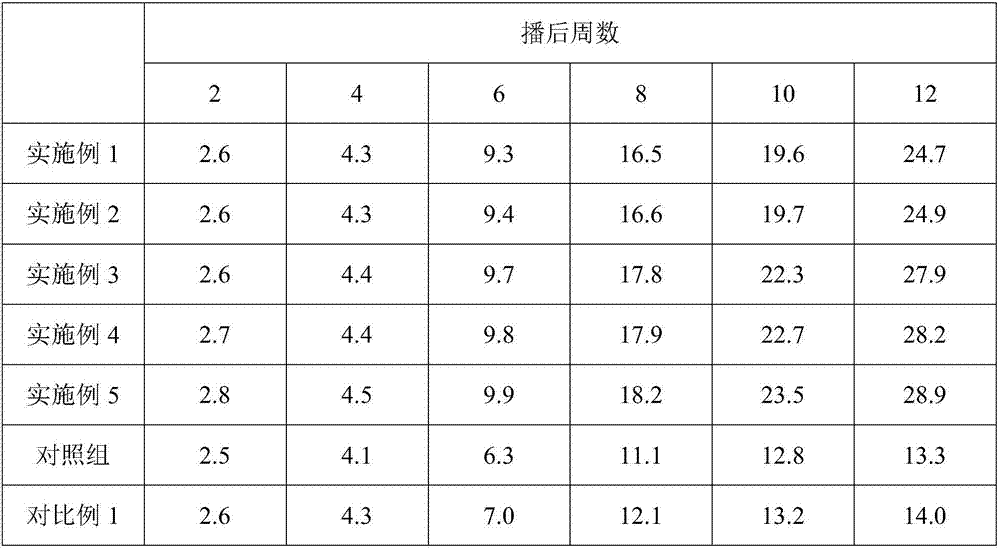

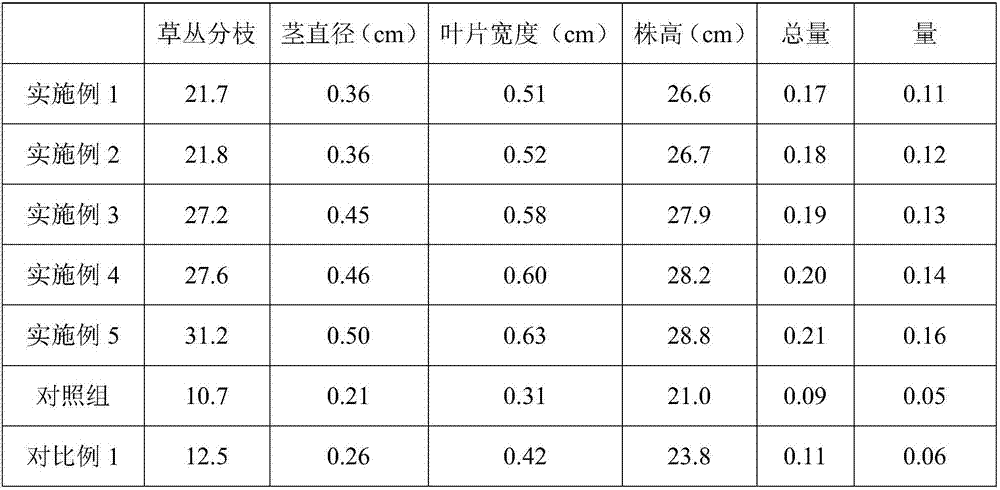

Examples

Embodiment 1

[0023] In an embodiment of the present invention, a composite material for ecological restoration includes the following raw materials: 31 kg of apatite, 7 kg of tetraethyl orthosilicate, 15 kg of chitosan, 42 kg of ageratum, and 13 kg of tea polyphenols.

[0024] Grind the ageratum, pass through a 100-mesh sieve, and then add an acetic acid solution whose mass is 4 times that of the acetic acid solution. The solvent of the acetic acid solution is water, and the mass concentration of the acetic acid solution is 30%. Then the temperature was raised to 55° C., heated and stirred at this temperature for 50 minutes, and then ultrasonically treated for 15 minutes with an ultrasonic power of 1000 W. The filtrate was collected by filtration and concentrated to 10% of its volume to obtain the Ageratum treatment product. Mix ethyl orthosilicate with ethanol 4 times its mass to prepare ethyl orthosilicate solution; crush apatite, pass through a 100-mesh sieve, and mix with ethyl orthosil...

Embodiment 2

[0026] In an embodiment of the present invention, a composite material for ecological restoration includes the following raw materials: 39kg of apatite, 15kg of tetraethyl orthosilicate, 25kg of chitosan, 50kg of ageratum, and 21kg of tea polyphenols.

[0027] Grind the ageratum, pass through a 150-mesh sieve, and then add an acetic acid solution 5 times its mass. The solvent of the acetic acid solution is water, and the mass concentration of the acetic acid solution is 35%. Then the temperature was raised to 60° C., heated and stirred at this temperature for 60 minutes, and then ultrasonically treated for 20 minutes with an ultrasonic power of 1000 W. The filtrate was filtered and concentrated to 15% of its volume to obtain the Ageratum treatment product. Mix ethyl orthosilicate with ethanol 5 times its mass to prepare ethyl orthosilicate solution; crush apatite, pass through a 150-mesh sieve, and mix with ethyl orthosilicate solution at a stirring speed of 250r / min Stirred f...

Embodiment 3

[0029] In an embodiment of the present invention, a composite material for ecological restoration includes the following raw materials: 33kg of apatite, 9kg of tetraethyl orthosilicate, 18kg of chitosan, 44kg of ageratum, and 15kg of tea polyphenols.

[0030] Grind the ageratum, pass through a 150-mesh sieve, and then add an acetic acid solution 4.5 times its mass, the solvent of the acetic acid solution is water, and the mass concentration of the acetic acid solution is 35%. Then the temperature was raised to 60° C., heated and stirred at this temperature for 55 minutes, and then ultrasonically treated for 20 minutes with an ultrasonic power of 1000 W. The filtrate was filtered and concentrated to 15% of its volume to obtain the Ageratum treatment product. Mix ethyl orthosilicate with 4.5 times the mass of ethanol to prepare ethyl orthosilicate solution; crush apatite, pass through a 150-mesh sieve, and mix with ethyl orthosilicate solution at a stirring speed of 250r / min Sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com