A method for preparing methane from pineapple dregs or mango dregs through anaerobic fermentation

A technology of anaerobic fermentation and pineapple pomace, applied in fermentation, waste fuel and other directions, can solve problems such as the influence of gas production, increase the volume of fermentation tank, etc., and achieve the effect of reducing investment budget and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

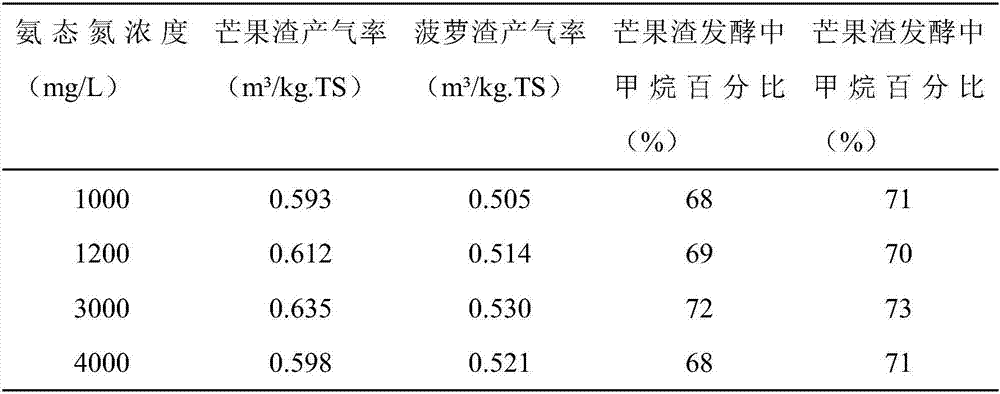

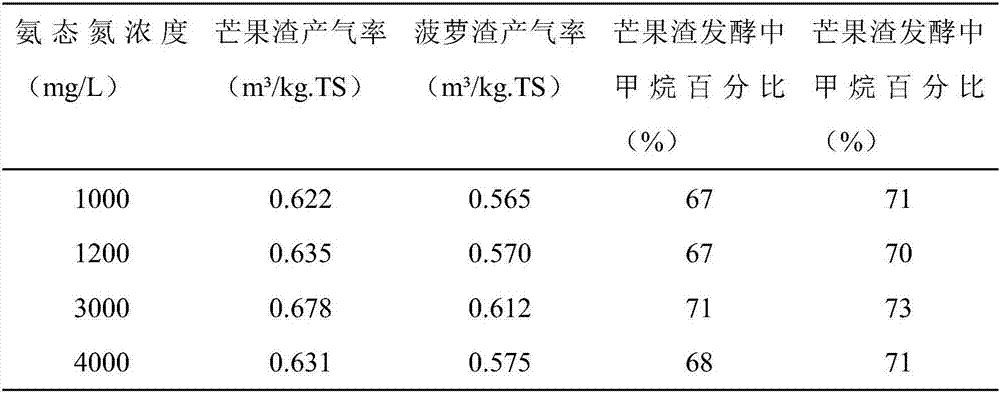

Examples

Embodiment 1

[0023] 1.1 Fermentation raw materials

[0024] 1.1.1 Pineapple pomace and mango pomace

[0025] In the experiment, pineapples and mangoes purchased from the market were simply processed. The leaves and pulp of the pineapples were removed, leaving only the skin of the pineapples. After being crushed with a cooking machine, they were wrapped in gauze and squeezed out the sugar water. The remaining slag was used as a raw material for fermentation. After the mango is pitted and pulped, only the mango skin is left. The follow-up treatment is the same as that of the mango, and the remaining dregs are used as fermentation raw materials. 1.1.2 Inoculum

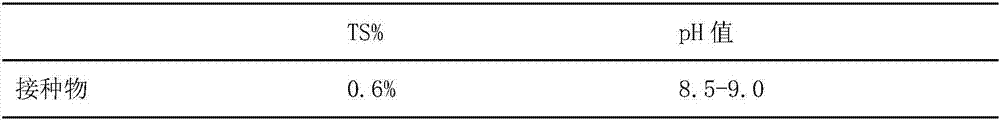

[0026] The inoculum of this test was taken from the biogas slurry of a pilot test of biogas production from kitchen waste in Chengdu, adding pineapple residue or mango residue, controlling the solid-liquid mass ratio to 6:100, controlling the ammoniacal nitrogen concentration to 2000 mg / L, and using pH The ammonia water is adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com