A kind of preparation method of high-strength dense titanium alloy-ceramic biocomposite material

A composite material and titanium alloy technology, applied in prosthesis, medical science and other directions, can solve the problems of poor wear resistance and difficult preparation of medical titanium alloys, and achieve the effect of improving mechanical properties, uniform sample composition and remarkable mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

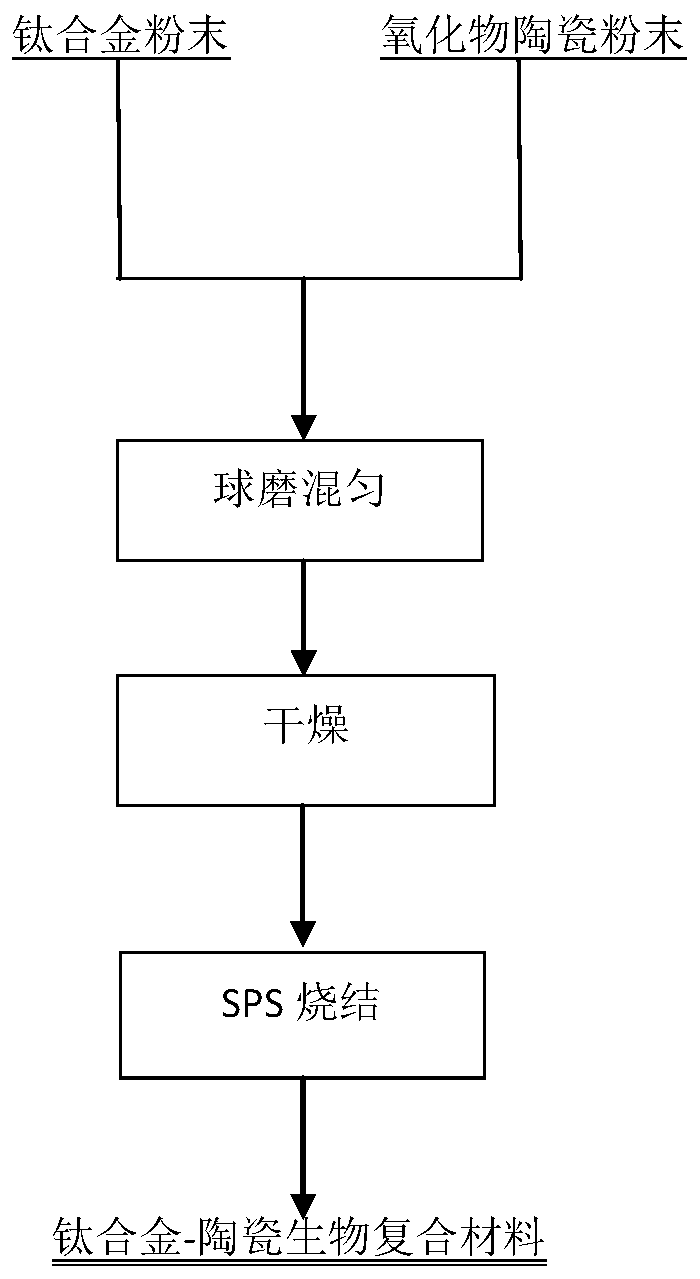

Method used

Image

Examples

Embodiment 1

[0019] (1) Ti2448 (Ti-24Nb-4Zr-8Sn, purchased from Institute of Metals, Chinese Academy of Sciences) and nano ZrO 2 Mix the ingredients according to the mass ratio of 95:5, then add the mixed material and zirconia grinding balls into the ball milling jar according to the mass ratio of 1:2, and add alcohol to two-thirds of the ball milling jar. Mixed material in planetary ball mill 300r·min -1 Medium ball milling for 10h. The ball-milled raw materials were dried at a constant temperature in a drying oven at 120°C.

[0020] (2) Put the dried composite powder into The graphite mold is wrapped with carbon paper around, up and down.

[0021] (3) Put the mold into the SPS furnace, evacuate until the vacuum degree drops below 10Pa, increase the furnace pressure to 50MPa, and set the sintering rate to 100°C min -1 , the sintering temperature was set at 1150°C, and the temperature was kept for 10 minutes. After the end, cool down with the furnace. According to the test, the samp...

Embodiment 2

[0023] (1) Ti2448 (Ti-24Nb-4Zr-8Sn, purchased from Institute of Metals, Chinese Academy of Sciences) and micron Y 2 o 3 Stabilized ZrO 2 (YSZ) Mix the ingredients at a mass ratio of 95:5, then put the mixed material and zirconia balls at a mass ratio of 1:2 into the ball milling jar, and add alcohol to two-thirds of the ball milling jar. Mixed material in planetary ball mill 300r·min -1 Medium ball milling for 10h. The ball-milled raw materials were dried at a constant temperature in a drying oven at 120°C.

[0024] (2) Put the dried composite powder into The graphite mold is wrapped with carbon paper around, up and down.

[0025] (3) Put the mold into the SPS furnace, evacuate until the vacuum degree drops below 10Pa, increase the furnace pressure to 50MPa, and set the sintering rate to 100°C min -1 , the sintering temperature was set at 1150°C, and the temperature was kept for 10 minutes. After the end, cool down with the furnace. According to the test, the density ...

Embodiment 3

[0027] (1) Ti2448 (Ti-24Nb-4Zr-8Sn, purchased from Institute of Metals, Chinese Academy of Sciences) and nano ZrO 2 Mix the ingredients according to the mass ratio of 90:10, then add the mixed material and zirconia grinding balls into the ball milling tank according to the mass ratio of 1:2, and add alcohol to two-thirds of the ball milling tank. Mixed material in planetary ball mill 300r·min -1 Medium ball milling for 10h. The ball-milled raw materials were dried at a constant temperature in a drying oven at 120°C.

[0028] (2) Put the dried composite powder into The graphite mold is wrapped with carbon paper around, up and down.

[0029] (3) Put the mold into the SPS furnace, evacuate until the vacuum degree drops below 10Pa, increase the furnace pressure to 50MPa, and set the sintering rate to 100℃·min -1 , the sintering temperature was set at 1150°C, and the temperature was kept for 10 minutes. After the end, cool down with the furnace. According to the test, the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive yield strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com