Molten salt storage tank insulation structure foundation

A storage tank and molten salt technology, applied in the field of solar power generation, can solve the problems of poor bottom heat dissipation, intolerance to deformation, and unsatisfactory heat insulation effect, and achieve the effects of avoiding temperature drop, good heat preservation effect, and small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

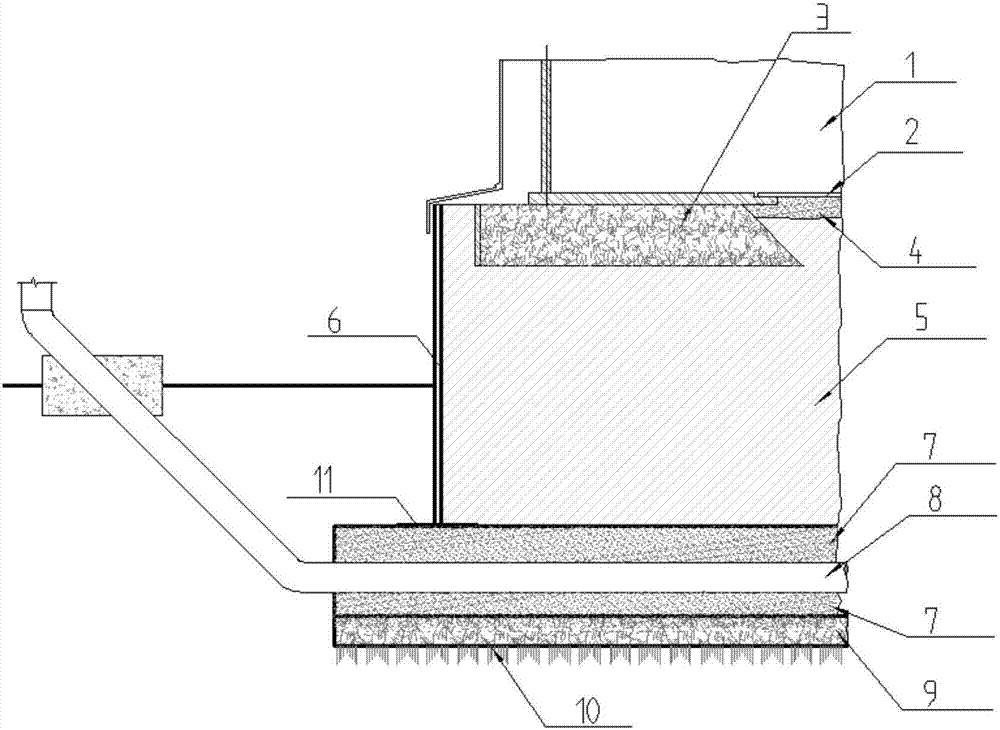

[0024] Such as figure 1 As shown, the thermal insulation structure foundation of a molten salt storage tank according to the present invention includes a deformation-resistant structure, a thermal insulation structure, and a reinforced concrete bottom plate 7 from top to bottom, wherein the steel ring wall 6 is placed on the reinforced concrete bottom plate 7, and the steel ring wall 6 is placed on the reinforced concrete bottom plate 7. An annular steel base 11 is provided on the contact surface between the ring wall 6 and the reinforced concrete bottom plate 7 , and a cushion layer 9 is provided under the reinforced concrete bottom plate 7 . The heat preservation structure is ceramsite 5 filled in the steel ring wall 6 . The deformation-resistant structure is a dry sand layer 4 close to the lower surface of the storage tank bottom plate 2. The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com