Lithium tantalate narrowband detector and preparation method thereof

A detector, lithium tantalate technology, used in electrical radiation detectors, instruments, measuring devices, etc., to achieve the effects of high integration, high sensitivity and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

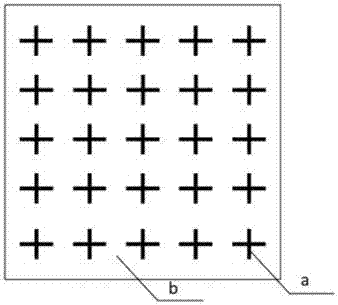

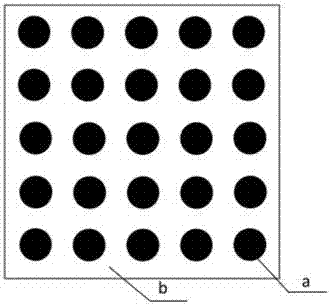

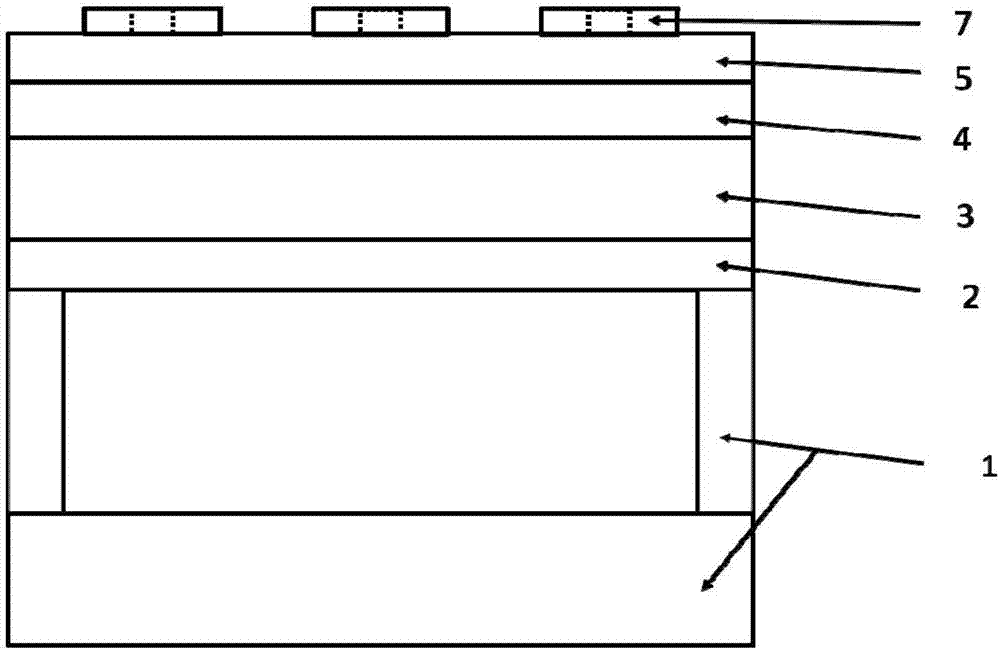

[0051] A lithium tantalate narrow-band detector based on a metasurface, each structural unit includes a silicon base and a support 1, a lower gold electrode 2, a lithium tantalate wafer 3, an upper electrode 4, a dielectric silicon 5, a cross Gold Antenna 7, such as figure 1 shown. Among them, the rod length of the cross gold antenna is 350nm, the rod width is 100nm, and the thickness of the cross gold antenna is 50nm; the unit structure period is 600nm; the thickness of the intermediate silicon layer is 50nm; the thickness of the gold backplane is 100nm. Through numerical simulation, the absorption spectrum of the structure in the infrared band is obtained, by Figure 5 It can be seen that the absorption peak wavelength of this structure is located at 3.24 microns.

Embodiment 2

[0053] A lithium tantalate narrow-band detector based on a metasurface, each structural unit includes a silicon base and a support 1, a lower gold electrode 2, a lithium tantalate wafer 3, an upper electrode 4, a dielectric silicon 5, a cross Gold Antenna 7, such as figure 1 shown. Among them, the rod length of the cross gold antenna is 500nm, the rod width is 100nm, and the thickness of the cross gold antenna is 50nm; the unit structure period is 700nm; the thickness of the intermediate silicon layer is 100nm; the thickness of the gold backplane is 100nm. Through numerical simulation, the absorption spectrum of the structure in the infrared band is obtained, by Figure 6 It can be seen that the absorption peak wavelength of this structure is located at 4.18 microns.

Embodiment 3

[0055] A lithium tantalate narrow-band detector based on a metasurface, each structural unit includes a silicon base and a support 1, a lower gold electrode 2, a lithium tantalate wafer 3, an upper electrode 4, a dielectric silicon 5, a cross Gold Antenna 7, such as figure 1 shown. Among them, the rod length of the cross gold antenna is 750nm, the rod width is 100nm, and the thickness of the cross gold antenna is 50nm; the unit structure period is 1200nm; the thickness of the intermediate silicon layer is 200nm; the thickness of the gold backplane is 100nm. Through numerical simulation, the absorption spectrum of the structure in the infrared band is obtained, by Figure 7 It can be seen that the absorption peak wavelength of this structure is located at 5.8 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com