Semiconductor device, manufacturing method thereof and electronic device

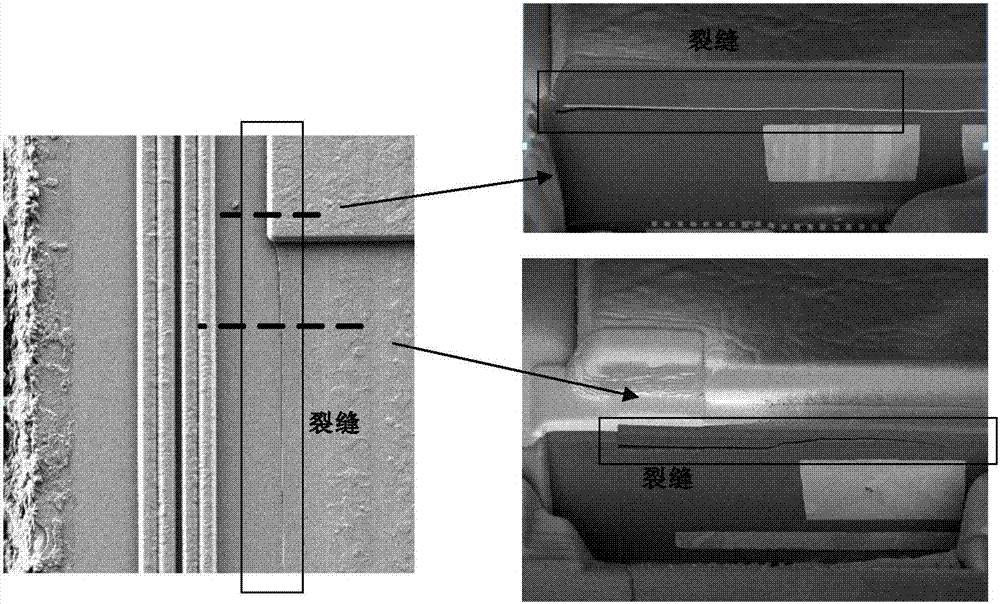

A manufacturing method and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as passivation layer cracks, improve toughness, improve performance and reliability, and improve integration problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

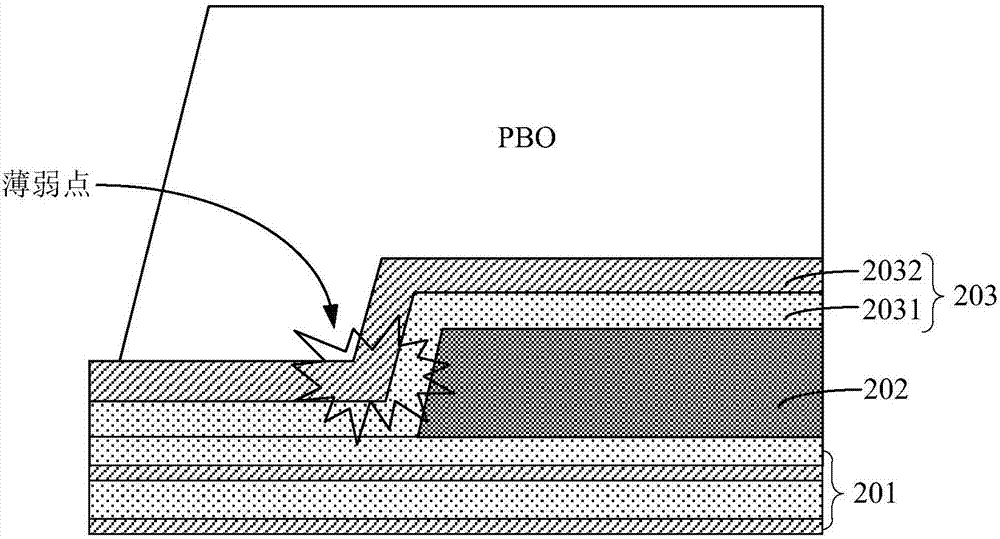

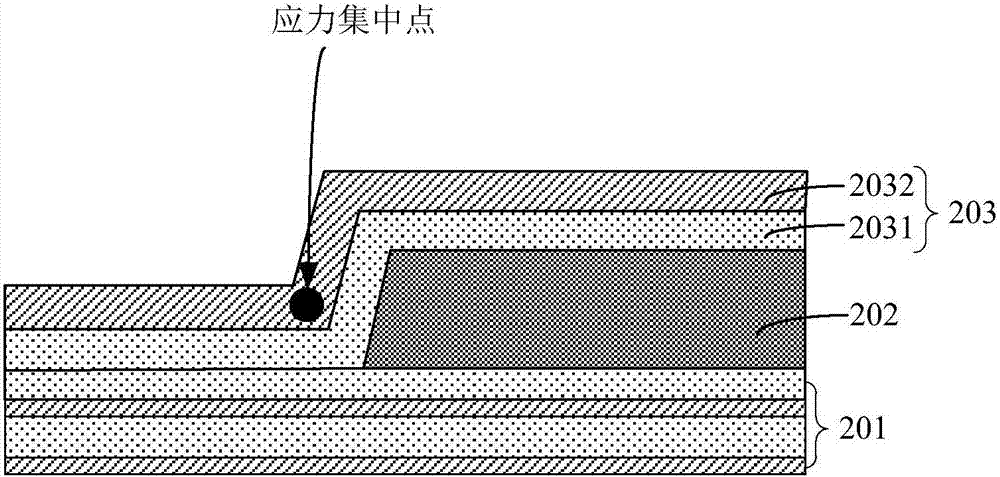

[0066] Below, refer to Figure 4 The structure of a semiconductor device according to an embodiment of the present invention is described in detail, wherein, Figure 4 A schematic cross-sectional view of a semiconductor device according to an embodiment of the present invention is shown.

[0067] The semiconductor device proposed by the present invention mainly includes the following components:

[0068] First, a substrate (not shown) is included.

[0069] Wherein, the base includes a semiconductor substrate, on which one or more active devices and passive devices can be formed, and the active devices can be transistors, diodes and other known active devices , the passive components can be resistors, capacitors and inductors and other known passive components, the substrate is connected to the pad to form an integrated circuit, but the substrate does not affect other aspects of the present invention The structure brings a key influence, so no specific limitation is imposed ...

Embodiment 2

[0105] The present invention also provides a method for manufacturing the foregoing semiconductor device, and the following continues to refer to Figure 4 as well as Figure 5 The manufacturing method of the semiconductor device of the present invention is described in detail.

[0106] The manufacturing method of semiconductor device of the present invention mainly comprises the following steps:

[0107] In step S501, a substrate is provided;

[0108] In step S502, several pad structures are formed on the base, wherein each of the pad structures is provided on the base with spaced protrusions, and the side walls of the pad structures and the base outside The surface forms a step angle;

[0109] In step S503, depositing and forming a top passivation layer covering the pad structure and the substrate around its outer side, wherein the top passivation layer includes a first oxide layer, a nitrogen layer stacked sequentially from bottom to top. A doped carbide layer and a fir...

Embodiment 3

[0148] Another embodiment of the present invention provides an electronic device, which includes a semiconductor device, the semiconductor device is the semiconductor device in the first embodiment above, or a semiconductor device manufactured according to the method for manufacturing a semiconductor device described in the second embodiment .

[0149] The electronic device can be any electronic product or equipment such as mobile phone, tablet computer, notebook computer, netbook, game console, TV, VCD, DVD, navigator, camera, video camera, recording pen, MP3, MP4, PSP, etc. It is an intermediate product with the above-mentioned semiconductor device, for example: a mobile phone motherboard with the integrated circuit, etc.

[0150] The electronic device also has the above-mentioned advantages due to the higher performance of the included semiconductor devices.

[0151] in, Figure 6 An example of a mobile phone handset is shown. The mobile phone handset 400 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com