Implementation method of large-range continuous adjustment of porosity of amorphous precursor ceramic

A realization method and precursor technology, applied in the field of large-scale continuous adjustment of the porosity of amorphous precursor ceramics, can solve the problems of destroying the integrity of bulk ceramics, ceramic cracks, etc., and achieve continuous adjustment, low price, and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

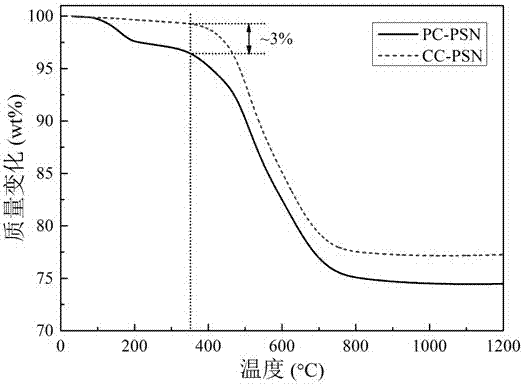

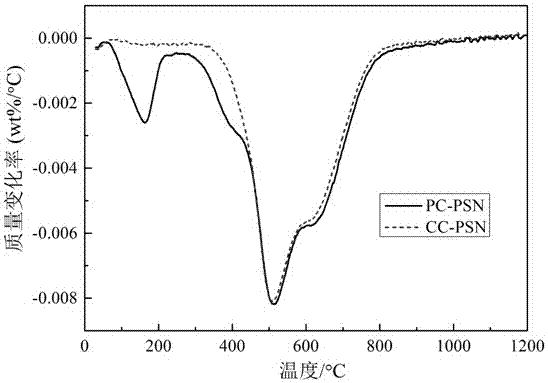

[0032] Specific implementation mode 1: This implementation mode records a method for realizing large-scale continuous adjustment of the porosity of amorphous precursor ceramics. The specific steps of the method are as follows:

[0033] Step 1: Preparation of partially cross-linked precursor: put the polysilazane precursor PSN into a tube furnace, raise the temperature to 150-200°C at a rate of 1.5-5°C / min under the protection of argon, and keep it warm for 30 ~60min to obtain partially cross-linked PC-PSN;

[0034] Step 2: Preparation of fully cross-linked precursor: put the polysilazane precursor PSN into a tube furnace, raise the temperature to 350°C at a rate of 1.5~5°C / min under the protection of argon, and keep it warm for 3 hours. Obtain fully cross-linked CC-PSN;

[0035] Step 3: Flour making: Ball mill the PC-PSN cross-linked and cured in Step 1 and the CC-PSN cross-linked and cured in Step 2 respectively, and pass through a 200-mesh standard sieve for 3 to 5 times; ...

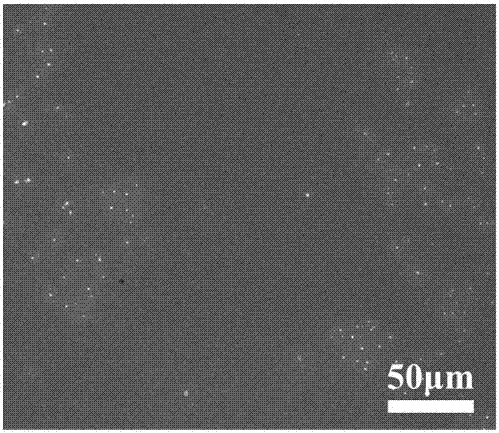

Embodiment 1

[0041] In this example, the proportion of CC-PSN in the precursor embryo body was 0 wt%, and the obtained precursor embryo body was completely dense. The pyrolyzed SiCN ceramics are also fully dense. Such as image 3 Shown is a photo of the microstructure of the SiCN ceramics prepared in this example.

[0042] The preparation method of fully dense SiCN ceramics is carried out as follows:

[0043] 1. Preparation of partially cross-linked precursors. Put the polysilazane precursor PSN into a tube furnace, raise it to 150-200°C at a rate of 1.5-5°C / min under the protection of argon, and keep it warm for 30-60 minutes to obtain a partially cross-linked PC- PSN;

[0044] Second, milling. Ball mill the cross-linked and solidified PC-PSN, and pass through a 200-mesh standard sieve for 3 to 5 times;

[0045] 3. Preparation of precursor bulk embryo bodies. The PC-PSN powder is hot-pressed. The whole hot-pressing process is carried out in a high vacuum environment (< 0.1Pa). The ...

Embodiment 2

[0048] In this example, the proportion of CC-PSN in the precursor embryo body was 25 wt%, and the precursor embryo body containing pores was obtained. The porosity of SiCN ceramics after pyrolysis is 4.82%. Such as Figure 4Shown is a photo of the microstructure of the SiCN ceramics prepared in this example.

[0049] The preparation method of 4.82% porosity SiCN ceramics is carried out as follows:

[0050] 1. Preparation of partially cross-linked precursors. Put the polysilazane precursor PSN into a tube furnace, raise it to 150-200°C at a rate of 1.5-5°C / min under the protection of argon, and keep it warm for 30-60 minutes to obtain a partially cross-linked PC- PSN;

[0051] 2. Preparation of fully cross-linked precursors. Put the polysilazane precursor PSN into a tube furnace, raise it to 350°C at a rate of 1.5~5°C / min under the protection of argon, and keep it warm for 3 hours to obtain a fully crosslinked CC-PSN;

[0052] Three, milling. Ball mill the cross-linked a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com