Photoresist coating system and on-line measurement method for viscosity thereof

A measurement method and photoresist technology, which is applied in the direction of DC flow characteristic measurement, photo-plate making process coating equipment, etc., can solve problems that affect the photolithography effect of products, abnormal coating film layer, and product defects, so as to ensure consistency and uniformity, simple method and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

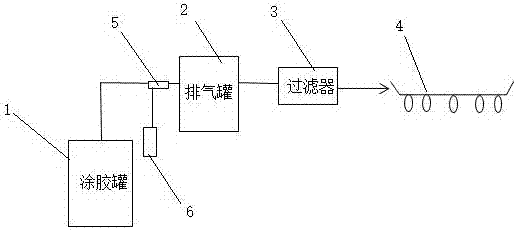

[0019] A photoresist coating system, comprising a glue application tank 1, an exhaust tank 2, a filter 3 and a glue application head 4 connected in sequence by a rubber hose, and the rubber hose between the glue application tank 1 and the exhaust tank 2 There is a three-way on-off control valve 5, the two ends of the three-way on-off control valve are respectively connected to the glue tank 1 and the exhaust tank 2 through rubber hoses, and the third end of the three-way on-off control valve 5 is connected to an online viscosity tester 6 . The online measurement method of adhesive viscosity is as follows: the three-way switch control valve 5 conducts the photoresist between the glue application tank 1 and the exhaust tank 2, turns on the switch leading to the photoresist viscosity tester 6, and measures the adhesive viscosity online.

Embodiment approach 2

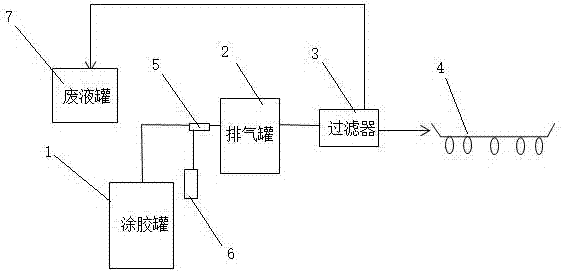

[0021] On the basis of Embodiment 1, a control system is also included, and the online viscosity tester 6 is connected to the control system. The filter 3 is also connected with a waste liquid tank 7 through a rubber hose, and the control system controls the glue application tank 1 , the exhaust tank 2 , the waste liquid tank 7 , the filter 3 and the glue application head 4 . The online measurement method of adhesive viscosity is: the control system controls the three-way switch control valve to conduct the photoresist between the glue application tank and the exhaust tank according to the predetermined parameters, and turns on the switch leading to the photoresist viscosity tester , online measurement of adhesive viscosity.

Embodiment approach 3

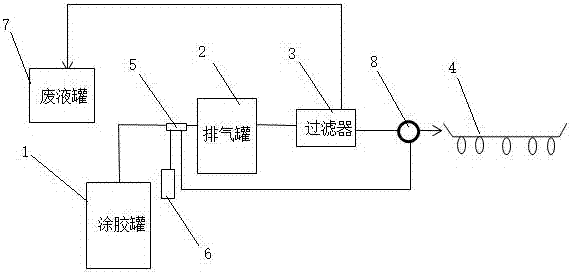

[0023] On the basis of Embodiment 2, a flow meter 8 is connected between the filter 3 and the glue applicator 4 through a rubber hose, and the flow meter 8 is electrically connected to the three-way switch control valve 5 . The flowmeter 8 is connected with the control system. The online measurement method of adhesive viscosity is: A. The control system controls the three-way switch control valve to conduct the photoresist between the glue application tank and the exhaust tank according to the predetermined parameters, and opens the photoresist viscosity tester switch, on-line measurement of adhesive viscosity;

[0024] B. When the control system reads the data in step A and shows "normal", close the switch leading to the photoresist viscosity tester; and feed back information to the flowmeter;

[0025] C. The control system reads the flow data of the photoresist in the flowmeter at any time;

[0026] D. When the control system reads the data in step C and displays "No", adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com