A METHOD OF DYNAMIC CHARACTERISTICS USING VIRTUAL MATERIAL EQUIVALENT BOLTED JOINTS

A technology of bolted joints and virtual materials, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the coupling of stiffness and damping models, the difficulty of simulating the dynamic characteristics of the overall structure, and the difficulty of improving the simulation accuracy of the overall structure and other problems to achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

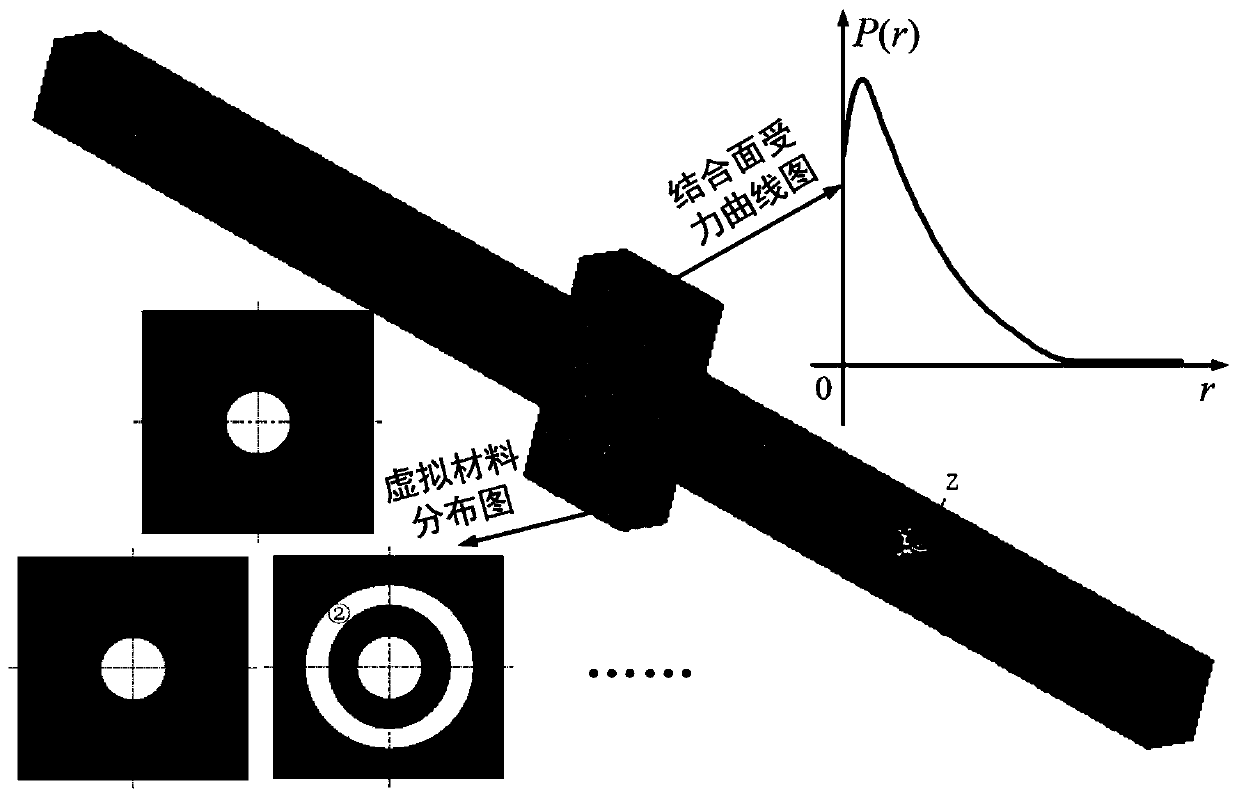

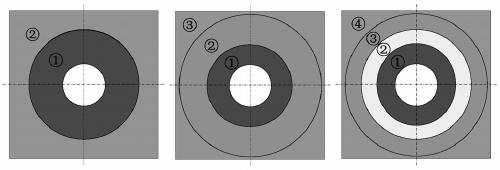

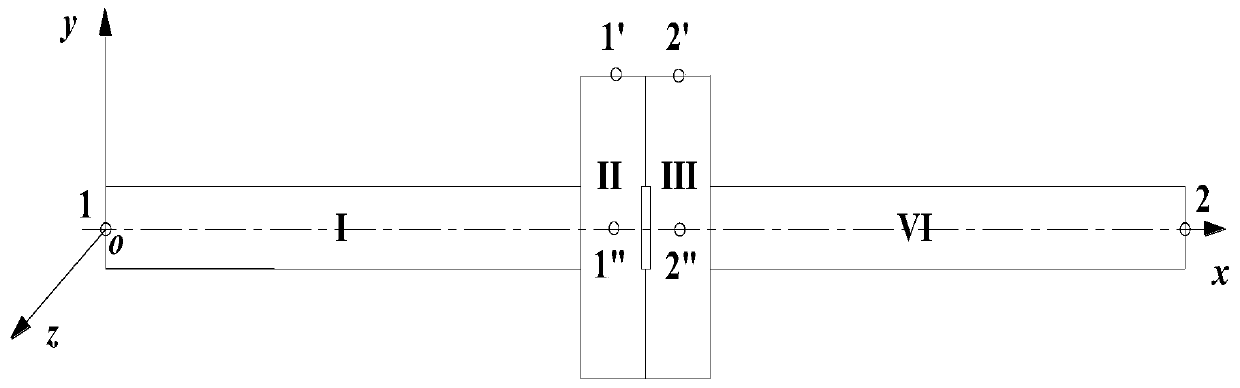

[0057] combine figure 1 , figure 2 and image 3 , the present invention is a method for utilizing virtual material equivalent bolted joint dynamic characteristics, comprising the following steps:

[0058] Step 1. Determine the contact compressive stress of the bolted joint. Assuming that the compressive stress is uniformly distributed in the direction vertical to the bolted joint, the size changes with the position in the r direction, and the compressive stress distribution is a truncated cone; the finite element method is used to simulate the bolted joint under different bolt pretightening forces, different The force of the contact area, the contact pressure P of the bolted joint n (r) is equivalent to a 4th order polynomial function about (r / a)

[0059]

[0060] In the formula, r represents the influence radius of the bolt force, a represents the radius of the bolt hole, and a 0 、a 1、a 2 、a 3 and a 4 is the correlation coefficient of the 4th order polynomial fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com