Processing method of lotus leaf tea powder

A processing method and lotus leaf technology are applied to the processing field of lotus leaf tea powder, which can solve the problems of reducing the health care efficacy of lotus leaf, insufficient aroma of lotus leaf, bitter taste and the like, and achieve good economic and social benefits, green color and taste. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

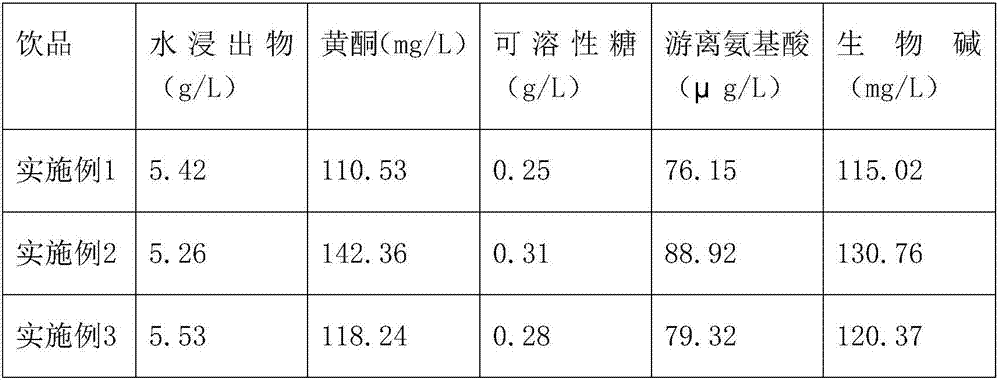

Examples

Embodiment 1

[0019] Embodiment 1, a kind of processing method of lotus leaf tea powder, carries out according to the following steps:

[0020] Step 1. Pick the lotus leaves that are fully bloomed in June as raw materials. After picking, spread out the lotus leaves, brush the front and back sides, and then rinse with running tap water. After washing, remove the leaf stems and thick veins of the lotus leaves. Peel off, keep only the fine veins, and then cut the lotus leaves into 1.5cm long and 0.5cm wide lotus leaves;

[0021] Step 2, spread the lotus leaves in step 1 in a cool place for greening treatment, the thickness of the lotus leaves is 5cm, and the spreading time is 30min;

[0022] Step 3, put the lotus leaves that have been spread green in step 2 into a microwave oven for degreening, the weight of the lotus leaves put into the microwave oven is 100g each time, the power of the microwave oven is 500w, and the degreening time is set to 60s;

[0023] Step 4, put the lotus leaves after...

Embodiment 2

[0027] Step 1: Pick the lotus leaves that are fully in full bloom in July. After picking, spread out the lotus leaves, brush the front and back sides, and then rinse with running tap water. After washing, peel off the stems and thick veins of the lotus leaves , keep only the fine leaf veins, and then cut the lotus leaves into 2cm, 0.8cm wide lotus leaves;

[0028] Step 2, spread the lotus leaves cut in step 1 in a cool place for greening treatment, the thickness of the lotus leaves is 5.5cm, and the spreading time is 45min;

[0029] Step 3: put the lotus leaves that have been greened in step 2 into a microwave oven for deenzyming. The weight of shredded lotus leaves in the microwave oven is 100g each time, the power of the microwave oven is 750w, and the deenzyming time is set to 120s;

[0030] Step 4: Put the lotus leaves that have been finished in step 3 into a kneading machine for cold kneading, set the rotation speed of the kneading machine to 50r / min, adjust the pressure ...

Embodiment 3

[0034] Step 1. Pick the lotus leaves that are fully in full bloom in July. After picking, spread out the lotus leaves, brush the front and back sides, and then wash them with running tap water. After washing, peel off the stems and thick veins of the lotus leaves , only keep the fine leaf veins, and then cut the lotus leaves into 2.5cm, 1cm wide lotus leaves;

[0035] Step 2, the lotus leaves in step 1 are spread in a cool place for green treatment, the thickness of the lotus leaves is 6cm, and the spreading time is 60min;

[0036] Step 3, put the lotus leaves that have been spread green in step 2 into a microwave oven for degreening. The weight of the lotus leaves put into the microwave oven is 100g each time, the power of the microwave oven is 600w, and the degreening time is set to 90s;

[0037] Step 4: put the lotus leaves after step 3 into the kneading machine for cold kneading, set the rotation speed of the kneading machine to 54r / min, adjust the pressure through the whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com