Ion chromatographic column preparation method which is semi-automatic and controlled by computer

An ion chromatographic column, semi-automated technology, applied in the field of ion chromatographic column preparation, can solve the problems of large separation performance of chromatographic column fillers, cumbersome preparation process of chromatographic column, and labor cost of using reagents, so as to reduce the harm to human body and environment, Good reproducibility and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

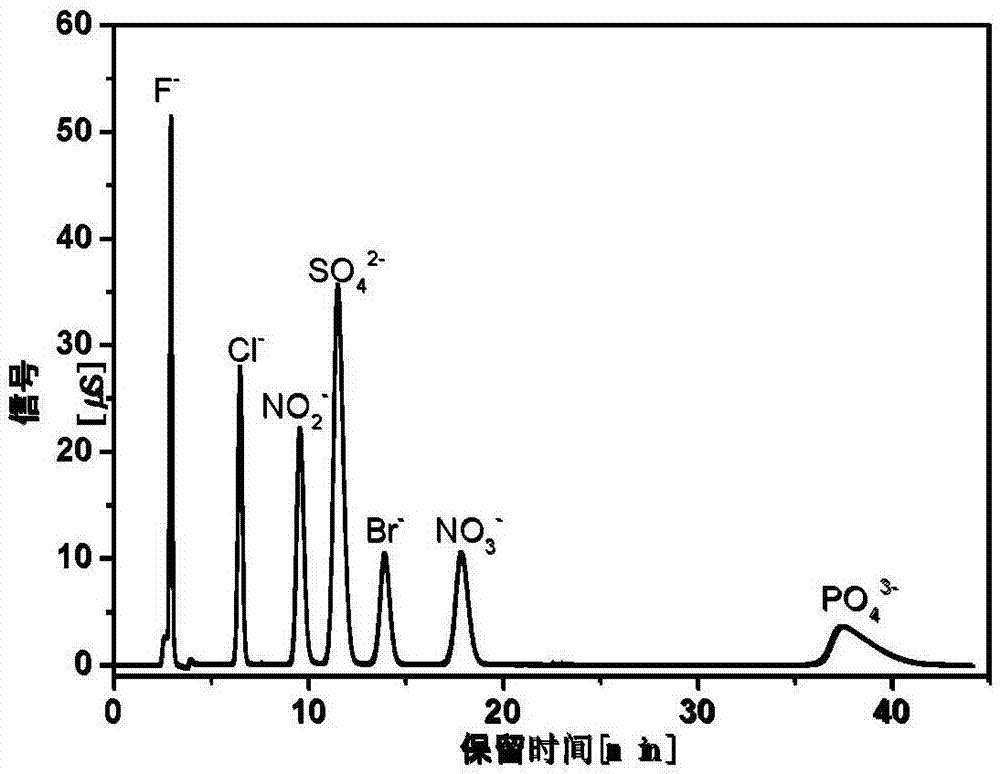

Embodiment 1

[0026] A semi-automatic and computer-controlled ion chromatography column preparation method, comprising the following four steps:

[0027] (1) Mix 3.5g of 10 micron PS / DVB microspheres with concentrated sulfuric acid at a volume ratio of 1:13, stir and react at 80°C for 2 hours, wash with ultrapure water until neutral, and obtain sulfonated microspheres. Disperse the thawed microspheres into water, and quickly pour them into a homogenization tank (connected to the column tube above) after ultrasonication for 10 minutes, pressurize to 20MPa and keep for 2 hours, replenish replacement water in time, and continue to rinse with ultrapure water for 30 minutes after the end.

[0028] (2) Prepare the following raw materials:

[0029] A: 0.3M mixed aqueous solution of 1,4-butanediol diglycidyl ether and methylamine; B: ultrapure water; C: 0.5M aqueous solution of 1,4-butanediol diglycidyl ether; D: 1.0 M methylamine aqueous solution.

[0030] (3) Connect the column tube containing ...

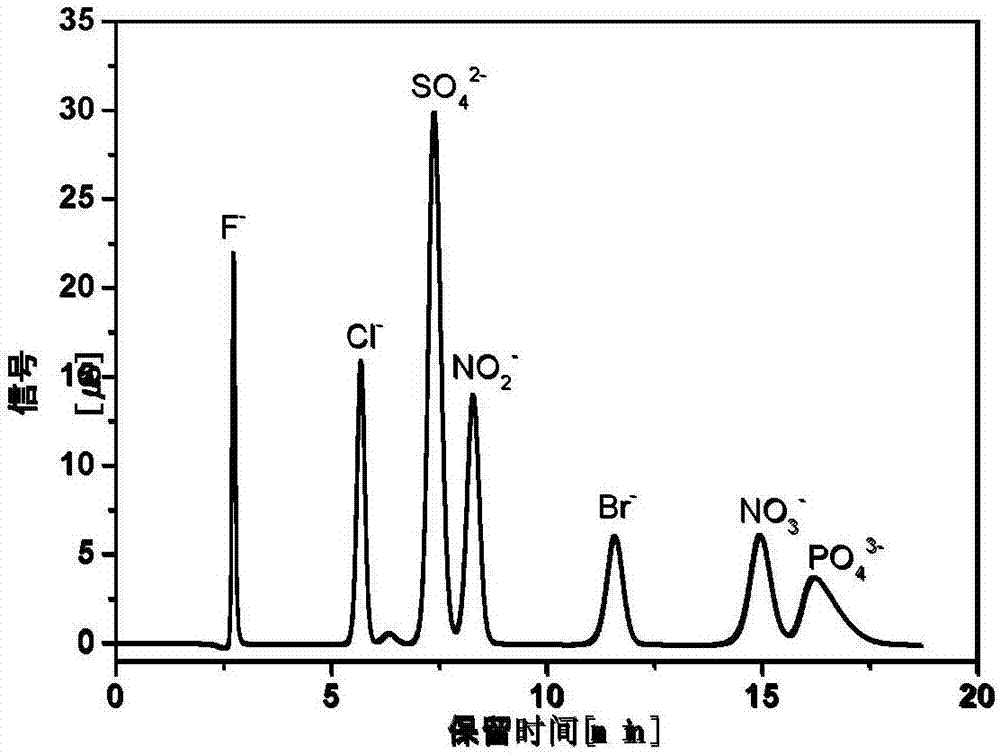

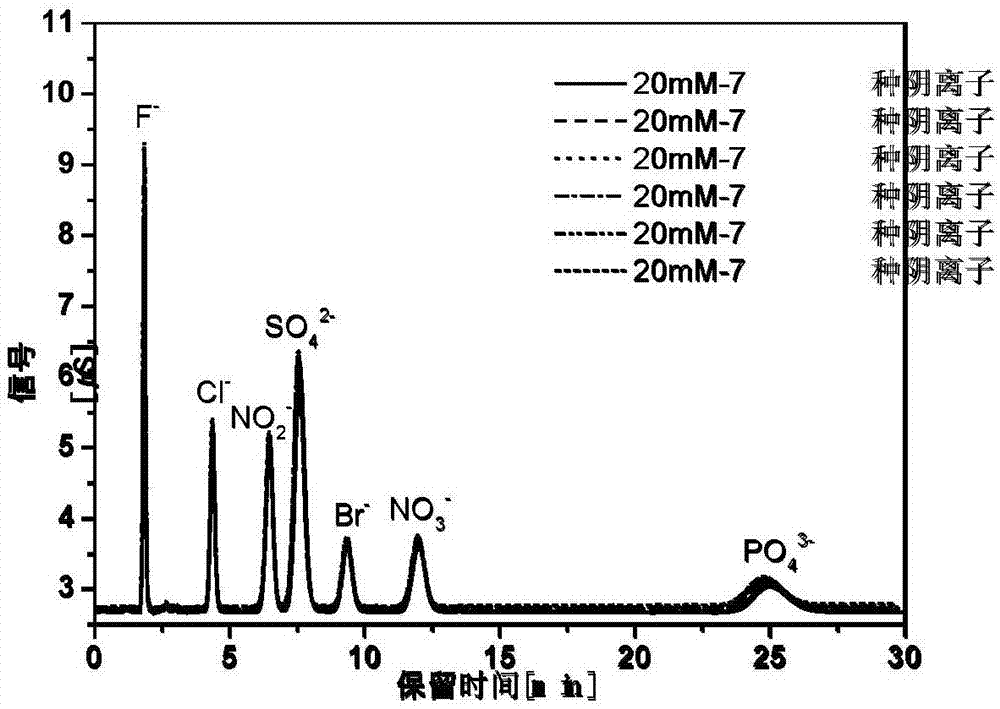

Embodiment 2

[0041] A semi-automatic and computer-controlled ion chromatography column preparation method, comprising the following four steps:

[0042] (1) Mix 3.5g of 10 micron PS / DVB microspheres with concentrated sulfuric acid at a volume ratio of 1:13, stir and react at 80°C for 2 hours, wash with ultrapure water until neutral, and obtain sulfonated microspheres. Disperse the thawed microspheres into water, and quickly pour them into a homogenization tank (connected to the column tube above) after ultrasonication for 10 minutes, pressurize to 20MPa and keep for 2 hours, replenish replacement water in time, and continue to rinse with ultrapure water for 30 minutes after the end.

[0043] (2) Types and concentrations of raw materials required for the preparation of chromatographic column packing:

[0044] A: 0.3M mixed aqueous solution of 1,4-butanediol diglycidyl ether and methylamine; B: ultrapure water; C: 0.5M aqueous solution of 1,4-butanediol diglycidyl ether; D: 1.0 M trimethyla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com