High-transparent and super-lubricating glass coating having self-supplement performance, and preparation method and application of same

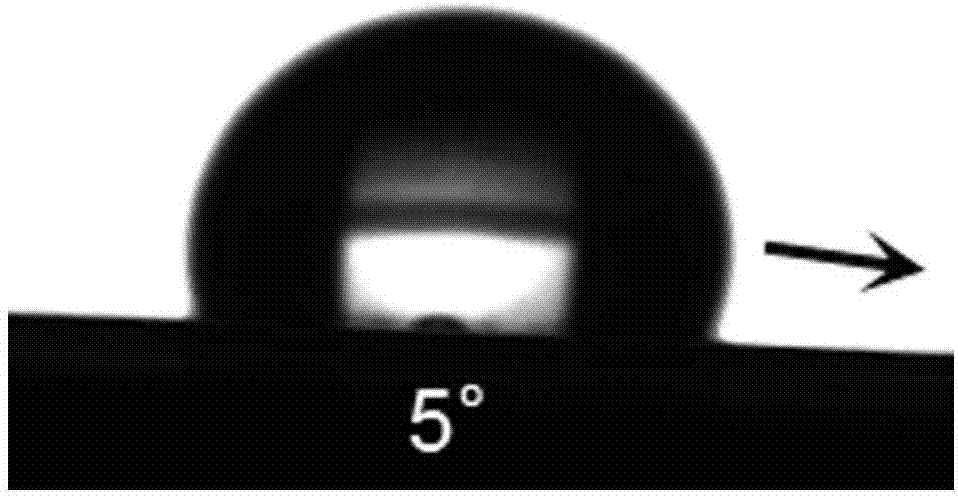

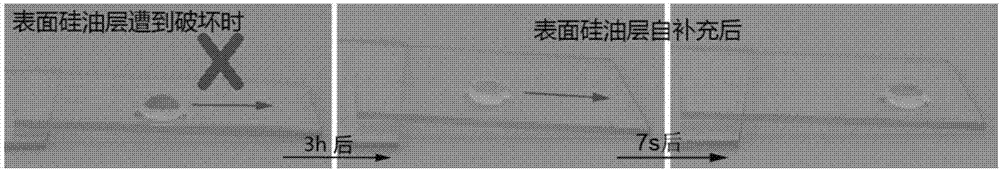

A self-replenishing and super-lubricating technology, applied in the coating and other directions, can solve the problems of tediousness and poor mechanical stability of the coating, and achieve the effects of simple process, increased added value, excellent transparency and super-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] cleaning of glass surfaces

[0035] At room temperature, put the glass slide in a beaker filled with ethanol, wash it in an ultrasonic bath for 10 minutes, then rinse the glass surface with deionized water, then put the glass slide in a beaker filled with deionized water, and wash it in an ultrasonic bath for 10 minutes. Clean the glass surface with deionized water, and finally blow dry the glass surface with nitrogen.

[0036] Preparation of PDMS coating

[0037] Add 5g of polydimethylsiloxane (PDMS) prepolymer and 0.5g of curing agent into 10ml of toluene, stir magnetically at room temperature for 1 hour to obtain a transparent and uniform solution, and spin coat the above solution on the surface of a glass slide with a homogenizer , and then placed in a 70°C oven to cure for 1h to obtain a PDMS coating;

[0038] Preparation of silicone oil-infused PDMS coating

[0039] The PDMS-coated glass was immersed in simethicone oil for 60 min, and the silicone oil-infused P...

Embodiment 2

[0043] cleaning of glass surfaces

[0044] At room temperature, put the glass slide into a beaker filled with ethanol, wash it in an ultrasonic water bath for 10 minutes, then rinse the glass surface with deionized water, then put the slide glass into a beaker filled with deionized water, wash it in an ultrasonic water bath for 10 minutes, and then rinse it with deionized water. Clean the surface with deionized water, and finally blow dry the glass surface with nitrogen.

[0045] Preparation of PDMS coating

[0046] Add 5g of polydimethylsiloxane (PDMS) prepolymer and 0.4g of curing agent into 10ml of toluene, stir magnetically at room temperature for 1h to obtain a transparent and uniform solution, and spin coat the above solution on the surface of a glass slide with a homogenizer. Then put it into a 70°C oven and cure for 1 hour to obtain a PDMS coating;

[0047] Preparation of silicone oil-infused PDMS coating

[0048] The PDMS-coated glass was immersed in simethicone oi...

Embodiment 3

[0051]cleaning of glass surfaces

[0052] At room temperature, put the glass slide into a beaker filled with ethanol, wash it in an ultrasonic bath for 10 minutes, then rinse the glass surface with deionized water, then put the slide glass into a beaker filled with deionized water, wash it in an ultrasonic water bath for 10 minutes, and then rinse it with deionized water. Clean the glass surface with deionized water, and finally blow dry the glass surface with nitrogen.

[0053] Preparation of PDMS coating

[0054] Add 5g of polydimethylsiloxane (PDMS) prepolymer and 0.35g of curing agent into 10ml of toluene, stir magnetically at room temperature for 1h to obtain a transparent and uniform solution, and spin coat the above solution on the surface of a glass slide with a homogenizer. Then put it into a 70°C oven and cure for 1 hour to obtain a PDMS coating;

[0055] Preparation of silicone oil-infused PDMS coating

[0056] The PDMS-coated glass was immersed in simethicone oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sliding angle | aaaaa | aaaaa |

| Sliding angle | aaaaa | aaaaa |

| Sliding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com