Gangue floating bead thermal-insulation concrete and preparation method and application thereof

A technology of thermal insulation concrete and coal gangue, applied in the field of building materials, can solve problems affecting crop growth, endangering human health, soil pollution, etc., and achieve the effects of promoting recycling, improving building anti-seismic performance, and increasing building floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

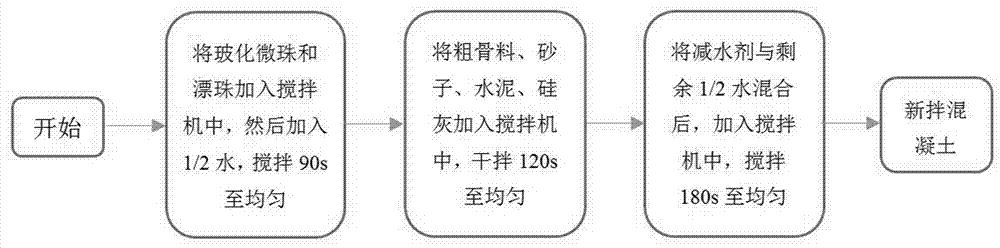

Method used

Image

Examples

Embodiment 1

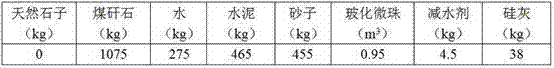

[0034] According to the preparation method of coal gangue floating pearl thermal insulation concrete of the present invention, the coarse aggregate adopts the above-mentioned coarse aggregate combination 1, and the coal gangue floating pearl thermal insulation concrete is 1m 3 The matching ratio is shown in Table 1.

[0035] Table 1 Mixing ratio of coal gangue floating beads insulation concrete

[0036]

Embodiment 2

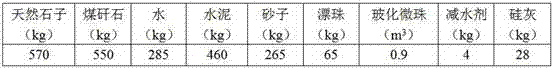

[0038] According to the preparation method of coal gangue floating pearl thermal insulation concrete of the present invention, the coarse aggregate adopts the above-mentioned coarse aggregate combination 2, and the coal gangue floating pearl thermal insulation concrete is 1m 3 The matching ratio is shown in Table 2.

[0039] Table 2 Mixing ratio of coal gangue floating beads insulation concrete

[0040]

Embodiment 3

[0042] According to the preparation method of coal gangue floating bead thermal insulation concrete of the present invention, the coarse aggregate adopts the above-mentioned coarse aggregate combination three, and the coal gangue floating pearl thermal insulation concrete is 1m 3 The matching ratio is shown in Table 3.

[0043] Table 3 Mixing ratio of coal gangue floating beads insulation concrete

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com