Synthetic method of low-viscosity polyvinyl butyral resin

A technology of polyvinyl butyral resin and polyvinyl alcohol, which is applied in the field of preparation of organic polymer compounds, can solve the problems of difficult control of distribution and side reactions, poor product batch stability, and low production efficiency, and achieve strong molecular Designability, good batch stability, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 9

[0049] A kind of synthetic method of low-viscosity polyvinyl butyral resin, the steps are as follows:

[0050] a. Preparation of polyvinyl alcohol / n-butyraldehyde water emulsion:

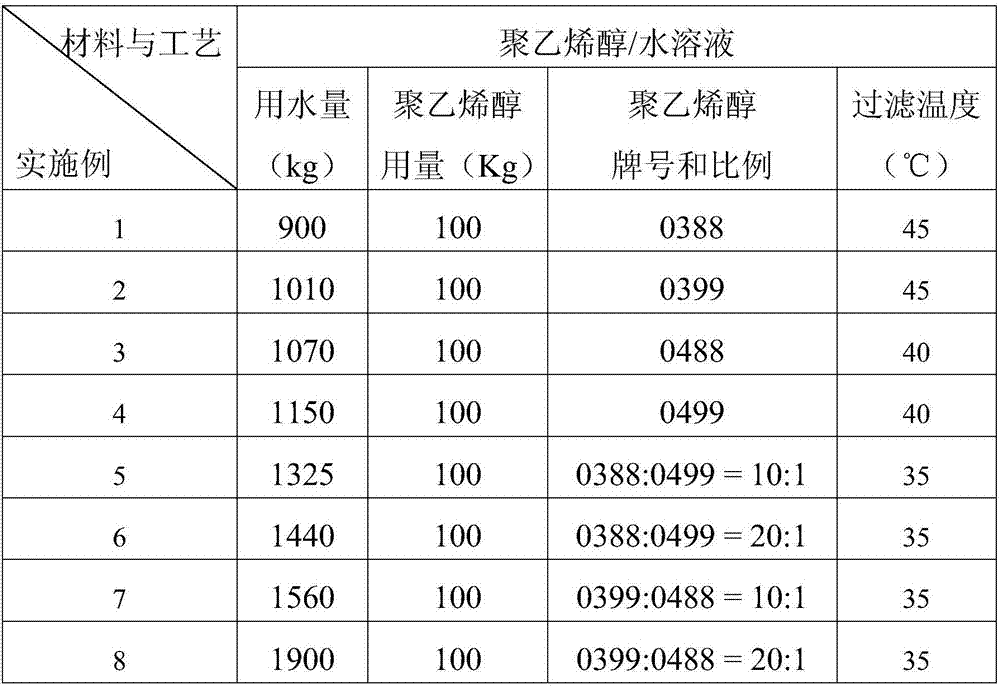

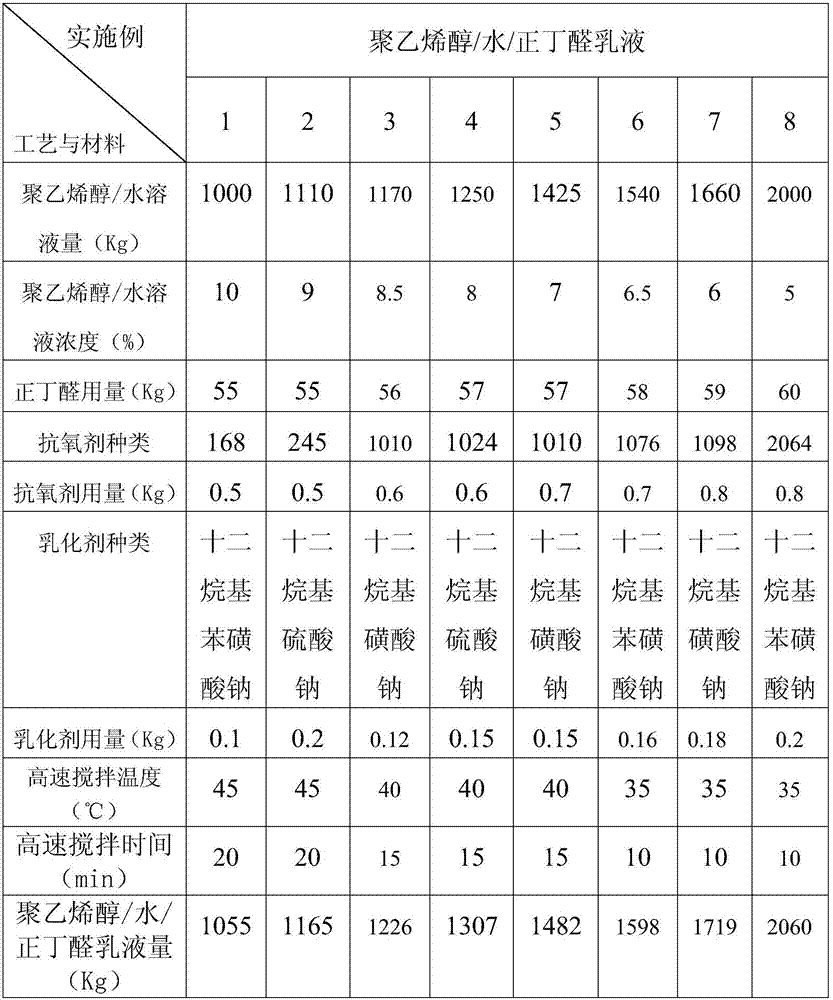

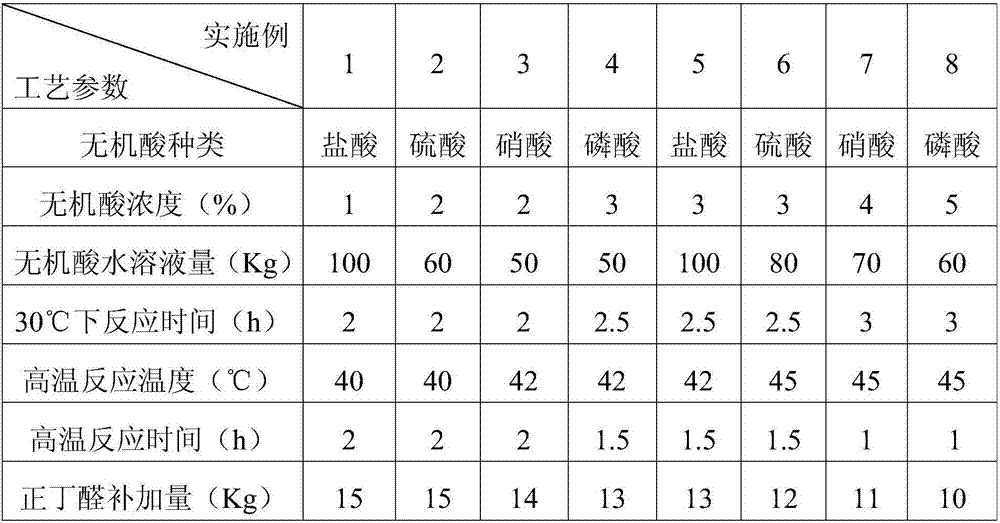

[0051] 100 parts by mass of low-viscosity polyvinyl alcohol and 900 parts by mass of water are fed. After feeding, the temperature is raised to 90° C. and kept for 2 hours (to completely dissolve the polyvinyl alcohol), and the temperature is lowered to 35° C. and filtered to obtain (mass percentage concentration of 10% ) polyvinyl alcohol aqueous solution, then drop into 55 parts by mass of n-butyraldehyde, 0.5 parts by mass of antioxidant, 0.1 part by mass of emulsifier, and stir at 35°C (at high speed) for 20min to obtain a polyvinyl alcohol / n-butyraldehyde aqueous emulsion, Cool the polyvinyl alcohol / n-butyraldehyde aqueous emulsion to below 10°C for later use;

[0052] Described low-viscosity polyvinyl alcohol can be any one or the mixture of two or more in the polyvinyl alcohol (being called ...

Embodiment 10

[0059] A kind of synthetic method of low-viscosity polyvinyl butyral resin, the steps are as follows:

[0060] a. Preparation of polyvinyl alcohol / n-butyraldehyde water emulsion:

[0061] 100 parts by mass of low-viscosity polyvinyl alcohol and 1900 parts by mass of water are fed. After feeding, the temperature is raised to 98° C. and kept for 2 hours (so that the polyvinyl alcohol is completely dissolved), and the temperature is lowered to 45° C. and filtered to obtain (mass percentage concentration of 5% ) polyvinyl alcohol aqueous solution, then drop into 60 parts by mass of n-butyraldehyde, 0.8 parts by mass of antioxidant, 0.2 parts by mass of emulsifier, and stir at 45°C (high speed) for 20min to obtain a polyvinyl alcohol / n-butyraldehyde aqueous emulsion, Cool the polyvinyl alcohol / n-butyraldehyde aqueous emulsion to below 10°C for later use;

[0062] Described low-viscosity polyvinyl alcohol can be any one or the mixture of two or more in the polyvinyl alcohol (being ...

Embodiment 11

[0069] A kind of synthetic method of low-viscosity polyvinyl butyral resin, the steps are as follows:

[0070] a. Preparation of polyvinyl alcohol / n-butyraldehyde water emulsion:

[0071] 100 parts by mass of low-viscosity polyvinyl alcohol and 1500 parts by mass of water are fed. After feeding, the temperature is raised to 94° C. and kept for 2 hours (so that the polyvinyl alcohol is completely dissolved), and the temperature is lowered to 40° C. and filtered to obtain (mass percentage concentration of 6.25%) ) polyvinyl alcohol aqueous solution, then drop into 58 parts by mass of n-butyraldehyde, 0.7 parts by mass of antioxidant, 0.15 parts by mass of emulsifier, and stir at 40°C (high speed) for 15min to obtain polyvinyl alcohol / n-butyraldehyde water emulsion, Cool the polyvinyl alcohol / n-butyraldehyde aqueous emulsion to below 10°C for later use;

[0072] Described low-viscosity polyvinyl alcohol can be any one or the mixture of two or more in the polyvinyl alcohol (being...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com