Water-based PU elastic coating and preparation method thereof

An elastic coating and water-based technology, applied in polyurea/polyurethane coatings, coatings, latex paints, etc., can solve the problems of large pollutant emissions, achieve the effects of reduced pollutant emissions, good elasticity, and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

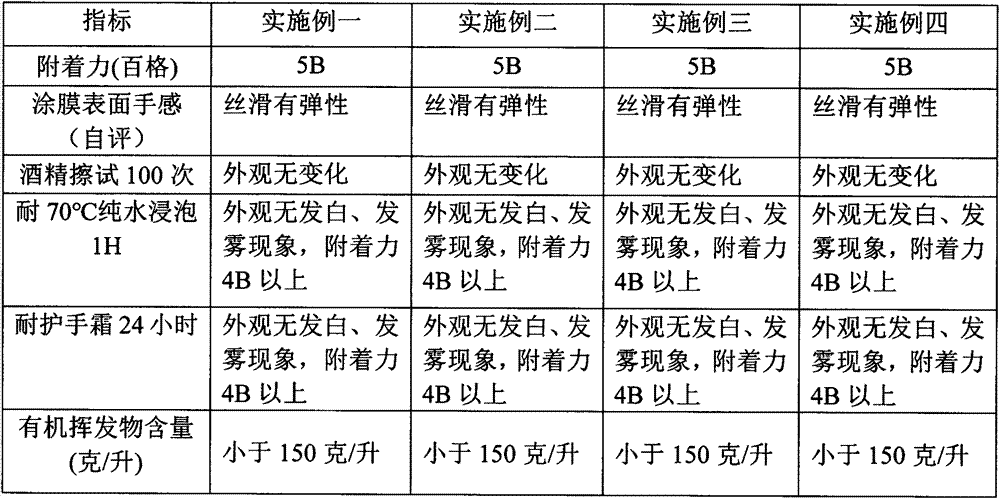

[0024] Embodiment: the present invention provides a kind of water-based PU elastic paint, and its component is according to following different embodiments, corresponding proportioning by weight content, see Table 1 for details:

[0025] Table 1: Component A

[0026]

Embodiment one

Embodiment two

Embodiment Three

Embodiment four

Waterborne Polyester Resin

40

45

50

55

Water-dispersed polycarbonate diol

15

15

12

10

pure water

20

18

18

10

Dispersant

1

1.5

1

2

matting powder

6

7

5

5

Anti-settling agent

2

1.5

1

2

9

7

6

10

D

1

0.5

1

0.5

leveling agent

1

1

0.5

0.5

Special Polyurethane Particles

4

3

5

4

Ammonia neutralizer

1

0.5

0.5

1

[0027] The water-based polyester resin adopts Nanchang Yushi Technology PS2100B, and the coating fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com