Method for obtaining mixed aromatics by cracking of C9 and hydrogenated separation

A technology for the separation of mixed aromatics and hydrogenation, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, hydrocarbon oil treatment products, etc. It can solve the problems of less than industrial application, less research, and low content of aromatics, and achieve Achieve long-term stable operation and improve the effect of appreciation utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

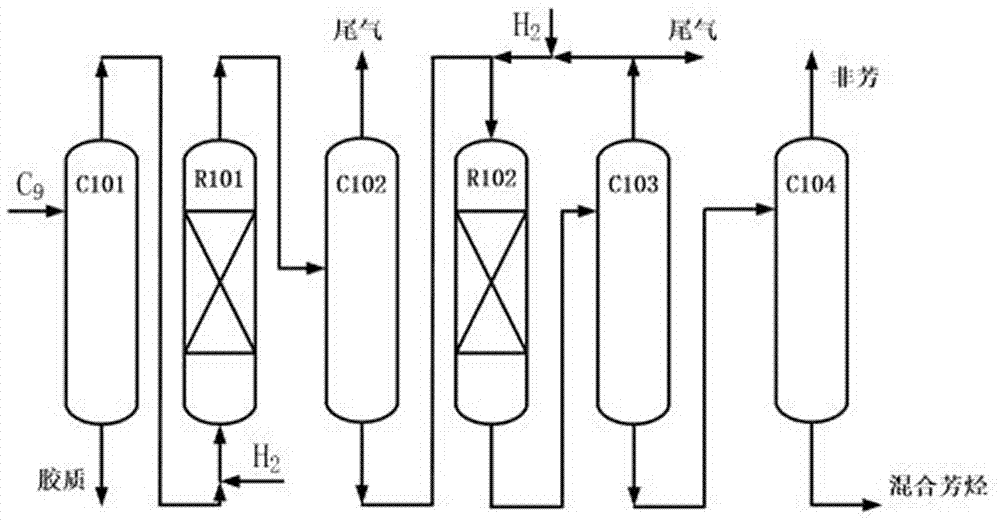

Embodiment 1

[0025] The raw material for cracking C9 first enters C101, the temperature of the tower kettle is 120°C, and the pressure is 0.1Mpa; the top material of C101 enters from the bottom of R101, the catalyst is a Ni-based catalyst, the reaction inlet temperature is 55°C, the pressure is 3.5Mpa, the hydrogen-oil volume ratio is 200; the R101 outlet material is separated by C102 and enters the top of R102 from the tower kettle, the catalyst is a Ni-Mo catalyst, the reaction inlet temperature is 180°C, the pressure is 3.5Mpa, and the hydrogen-oil volume ratio is 600; the R102 outlet material is separated by C103 Then it enters the C104 rectification tower from the bottom of the tower. The temperature of the bottom of the tower is 90°C and the pressure is 0.2Mpa. The output of the bottom of the tower is mixed aromatics, of which the recovery rate of mixed aromatics is 96.5%, and the non-aromatic content is 0.35%.

Embodiment 2

[0027] The method is the same as that of Example 1, except that the R101 and R102 catalysts are, the R101 catalyst is a Pd-based catalyst, and the R1020 catalyst is a Co-Mo-based catalyst. The recovery rate of mixed aromatics was 95.5%, and the non-aromatic content was 0.47%.

Embodiment 3

[0029] The method is the same as that of Example 1, except that the R101 and R102 catalysts are, the R101 catalyst is a Ni-based catalyst, and the R1020 catalyst is a Co-Mo-based catalyst. The recovery rate of mixed aromatics was 95.9%, and the non-aromatic content was 0.40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com