Prefabricated building block

A prefabricated, block technology, applied to pavements, roads, and pavement details paved with prefabricated blocks, can solve the problems of insufficient supporting structure strength, poor flatness, easy to be crushed, etc. The effect of high flatness and not easy to raise dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

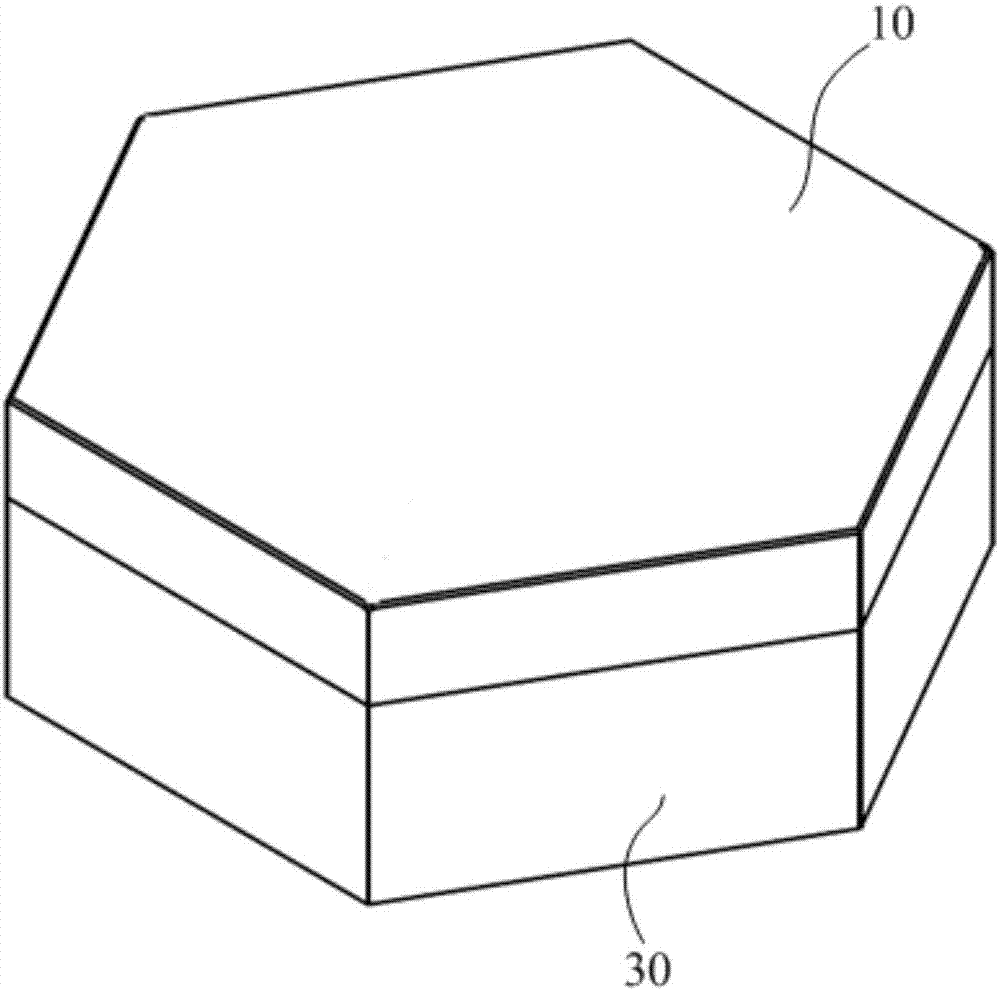

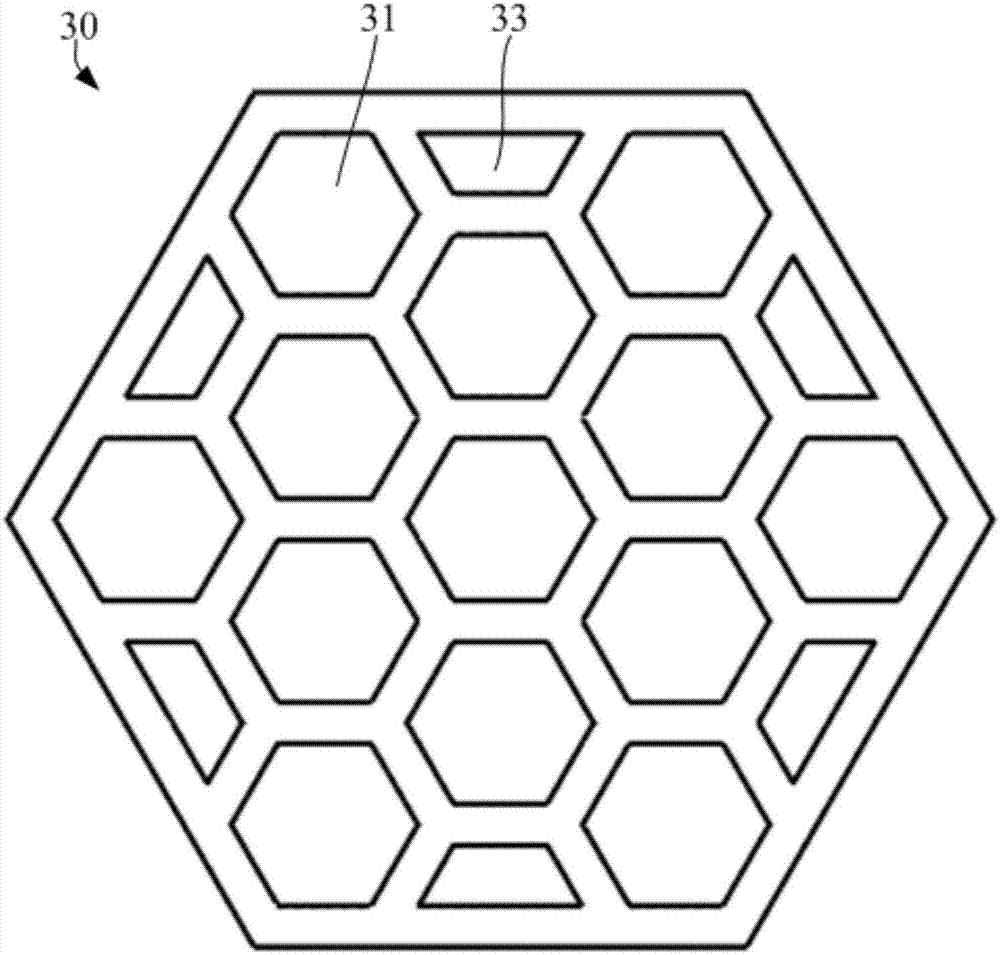

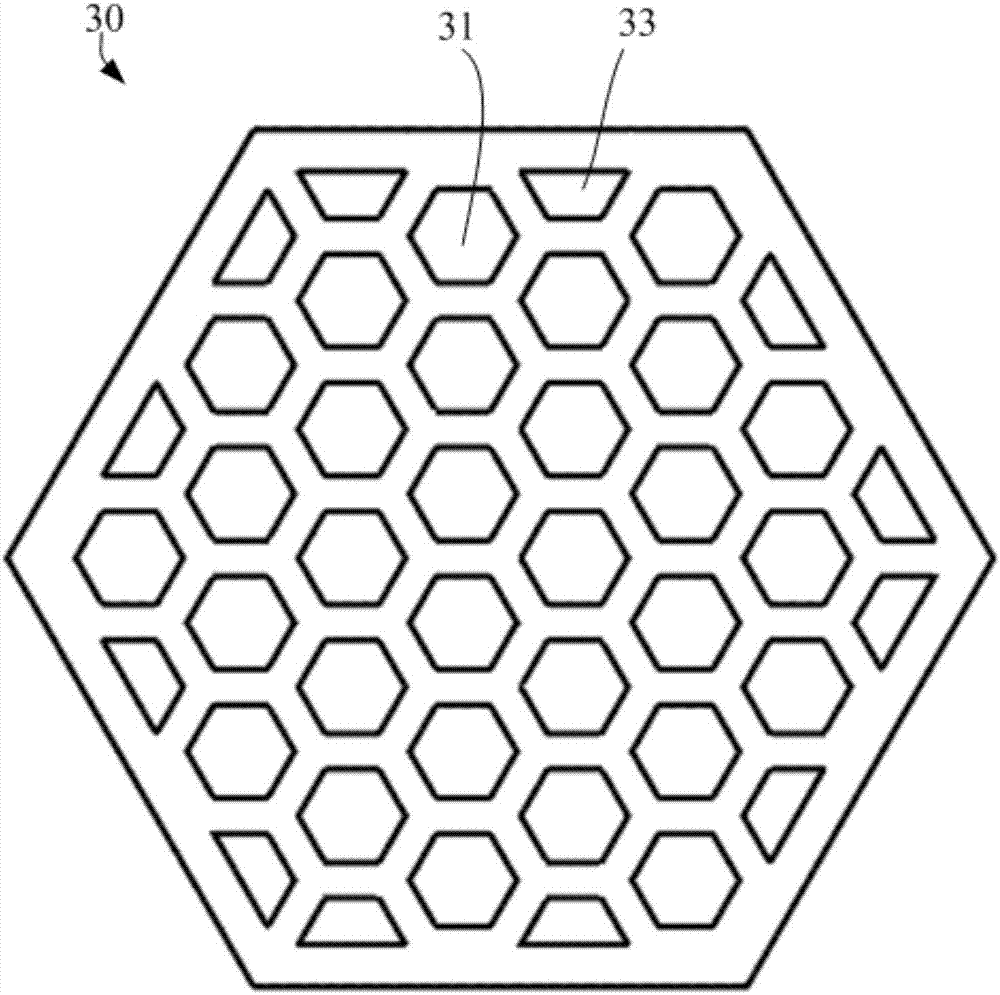

[0058] Such as Figure 1 to Figure 3 As shown, the prefabricated block provided in this embodiment includes two layers of a water-permeable surface layer 10 and a support layer 30 . The water-permeable surface layer 10 has water-permeable pores that can be used for water penetration; the support layer 30 is arranged under the water-permeable surface layer 10 for providing support to the water-permeable surface layer 10, wherein the support layer 30 in this embodiment is a polygonal prism, and its cross-section The outer contour is a regular hexagon, and the support layer 30 is formed with a plurality of first openings 31 set through its upper and lower surfaces. The first opening 31 provided on the upper and lower surfaces, and then the assembled block of the present invention can realize the water permeable function, and at the same time, after the installation is completed, the first opening 31 on the support layer 30 can be connected with the impermeable water laid below it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com