Method for constructing station-system beating type production mode of subway train

A technology of production mode and construction method, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve the problems of chaotic operation management, high variability, low production efficiency, etc., and achieve good traceability, rapid processing, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

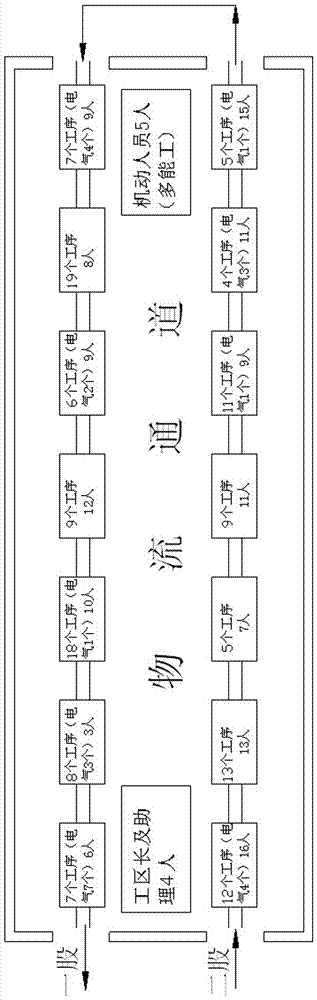

[0020] Embodiment: The construction method of metro train station system rhythmic production mode of this example, its steps are: establish standard station, the production assembly line of whole subway train is cut into independent standard station, namely product flows on the production line When the employee completes the specified work content within one beat, the relative position of the product stays, so that the operator and the delivery person are separated; the arrangement of the production line is U-shaped;

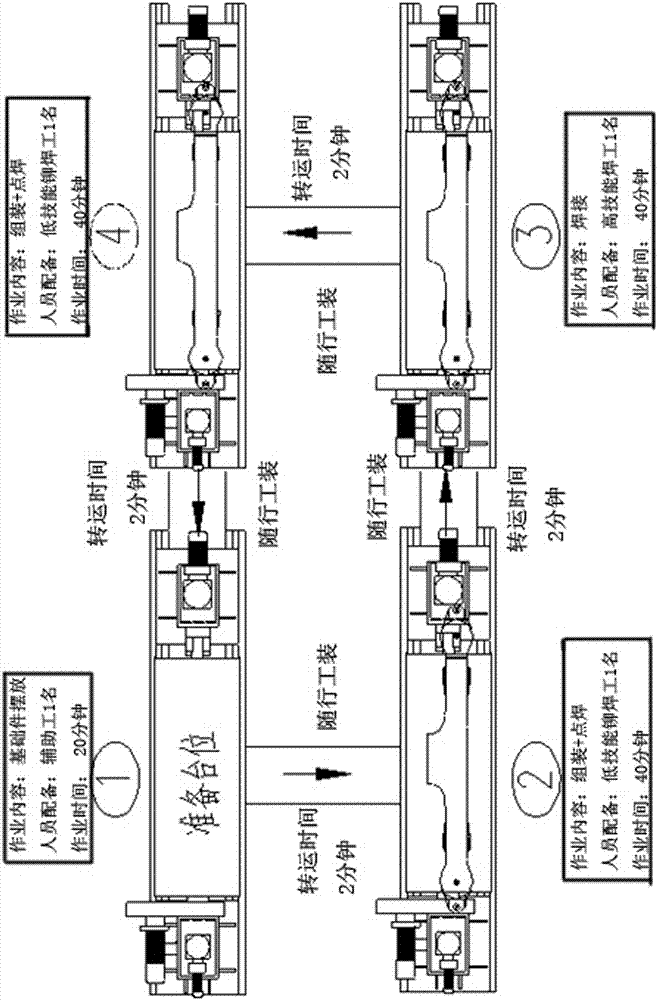

[0021] Determine the time to complete the same two products or two services or two batches of products in a row, that is, determine the beat; when determining the beat, it is necessary to make a process transition map and a mountain map of employee operations, standardize the operating standards, and ensure the production beat; figure 2 , Measuring the beat of group welding: No. 1 job content: basic parts placement, staffing: 1 assistant worker, working time: 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com