beta molecular sieve catalyst, preparation method and application

A technology of molecular sieves and catalysts, applied in the field of Beta molecular sieve catalysts, preparation and application, can solve the problems of high catalyst strength, low catalytic activity, low catalyst strength, etc., and achieve good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

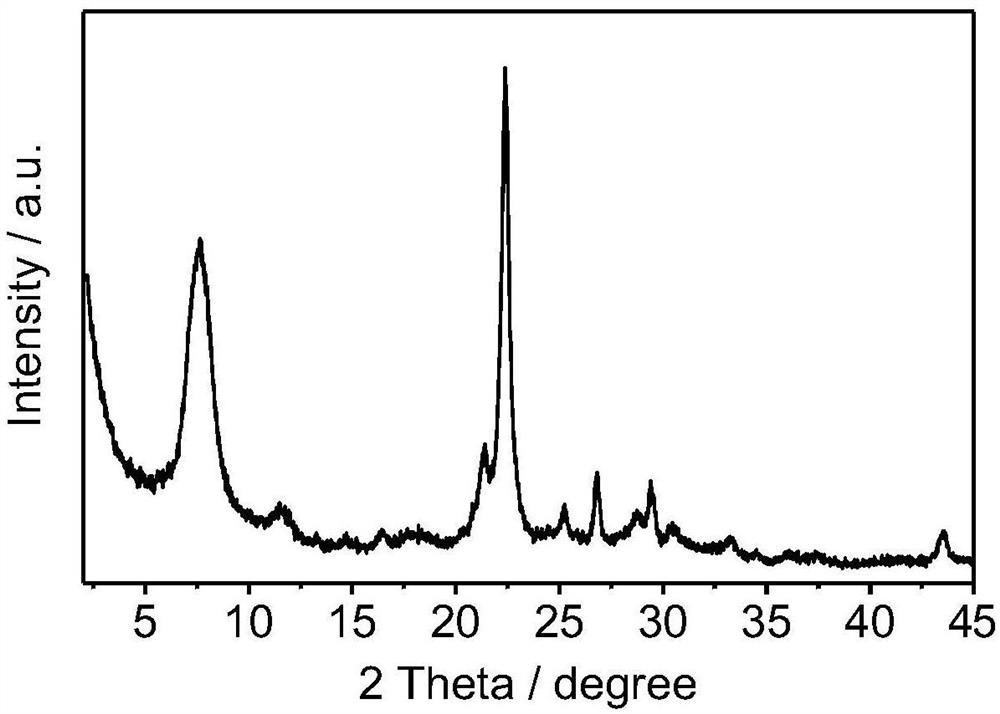

Image

Examples

Embodiment 1

[0050] a) Preparation of synthetic Beta molecular sieves: Alkaline silica sol, aluminum sulfate octadecahydrate, tetraethylammonium hydroxide (TEAOH) and water are used as synthetic raw materials, and the above raw materials are prepared according to the material ratio (molar ratio):

[0051] SiO 2 / Al 2 o 3 =25

[0052] TEAOH / SiO 2 =0.20

[0053] h 2 O / SiO 2 =18

[0054] After mixing evenly, put it into a stainless steel reaction kettle, and crystallize at 150°C for 5 days while stirring. After the crystallization is completed, filter, wash and dry to obtain the synthesized Beta molecular sieve. The weight loss rate of the synthesized Beta molecular sieve was tested to be 13.1% by weight by roasting at 550° C. for 5 hours in an air atmosphere.

[0055] b) Alkaline silica sol (SiO 2 40.0% by weight) is silicon source, sodium aluminate (Al 2 o 3 43.0 wt%, Na 2 (235.0% by weight) is the aluminum source, 0.25 gram of sodium aluminate is mixed with 48.1 gram of synt...

Embodiment 2

[0060] Same as [Example 1], except:

[0061] b) 59.6 grams of synthetic state Beta molecular sieve, alkaline silica sol (SiO 2 40.0% by weight) 4.5 grams, 1.05 grams of scallop powder, sodium aluminate (Al 2 o 3 43.0 wt%, Na 2 O 35.0% by weight) 0.25 grams are mixed evenly, silicon aluminum molar ratio SiO 2 / Al 2 o 3 =28.5, alkali-silicon molar ratio alkali / SiO 2 =0.094, a bar-shaped molecular sieve catalyst precursor with a Beta molecular sieve content of 96.3 wt%, a binder content of 3.7 wt%, and a four-leaf clover cross section was prepared by extrusion molding.

[0062] c) Calcining the Beta molecular sieve catalyst precursor I prepared in step b) at 550° C. under air atmosphere for 6 hours to obtain the Beta molecular sieve catalyst precursor II.

[0063] d) Contact the Beta molecular sieve catalyst precursor II prepared in step c) with a 15% ammonium nitrate solution at 60° C. for 3 times for 1 hour each time, separate the solid product, dry it, and roast it to...

Embodiment 3

[0065] Same as [Example 1], except:

[0066] b) 77.0 grams of synthetic Beta molecular sieves, alkaline silica sol (SiO 2 40.0% by weight) 4.5 grams, 1.05 grams of scallop powder, sodium aluminate (Al2 o 3 43.0 wt%, Na 2 O 35.0% by weight) 0.25 g and mix well. Molar ratio of silicon to aluminum to SiO 2 / Al 2 o 3 =28.5, alkali-silicon molar ratio alkali / SiO 2 =0.094, a strip-shaped molecular sieve catalyst precursor with a Beta molecular sieve content of 97.1% by weight, a binder content of 2.9% by weight, and a four-leaf clover cross section was prepared by extrusion.

[0067] c) Calcining the Beta molecular sieve catalyst precursor I prepared in step b) at 550° C. under air atmosphere for 6 hours to obtain the Beta molecular sieve catalyst precursor II.

[0068] d) Contact the Beta molecular sieve catalyst precursor II prepared in step c) with a 15% ammonium nitrate solution at 60° C. for 3 times for 1 hour each time, separate the solid product, dry it, and roast it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com