Stainless steel injection molding feed and preparation method thereof

An injection molding, stainless steel technology, applied in the direction of metal processing equipment, transportation and packaging, etc., can solve the problems of incomplete structure, low density, surface shrinkage, etc., and achieve the effect of high fusion, improved fusion, and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In another embodiment, a preparation method of the stainless steel injection molding feedstock includes: kneading the forming agent and the stainless steel feedstock powder according to the proportion, and extruding to granulate.

[0057] In a preferred embodiment, the preparation method comprises the following steps:

[0058] S1. Preheating the stainless steel feed powder to be mixed to 130-150°C;

[0059] S2. Add the forming agent into a kneader for heating and mixing until it becomes a molten dough, the kneader speed is 10-15r / min, and the kneading temperature is 150-170°C;

[0060] S3. Add the preheated stainless steel feed powder into the molten binder to continue mixing, keep the vacuum in the mixer, the speed of the mixer is 20-35r / min, and the set temperature is 150-170°C. Mixing time 20-40min;

[0061] S4. Extrude and granulate to prepare stainless steel injection molding feed.

[0062] In another embodiment, a method for manufacturing a product using the MI...

example 1

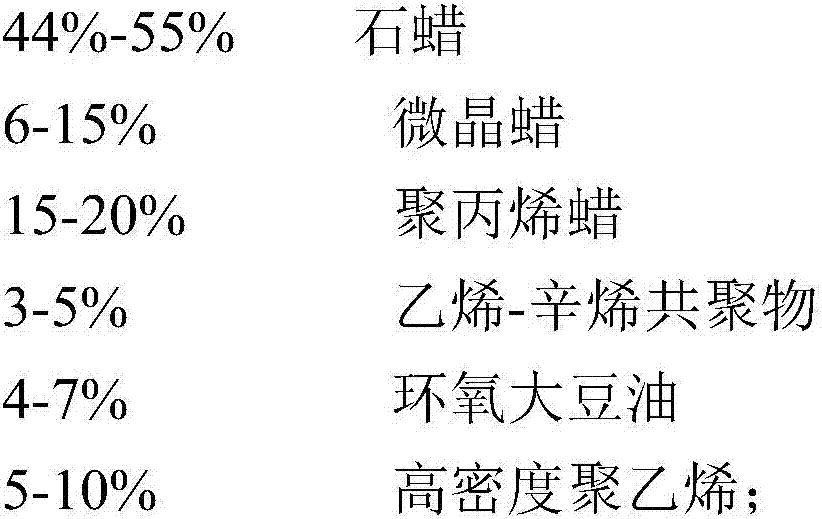

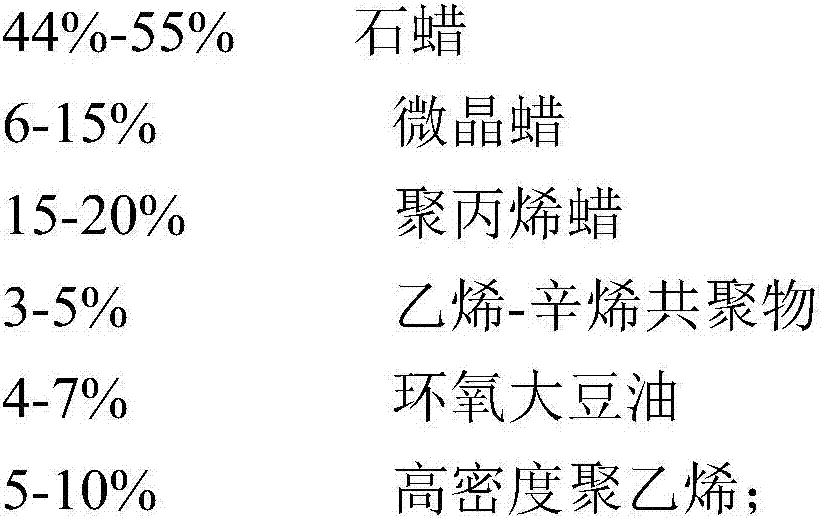

[0069] The feed consisted of the following components:

[0070]

[0071] Preparation of feed, and the process of using the feed to make MIM products:

[0072] S1. Heat the metal powder to be mixed to 130-150°C on a heating plate.

[0073] S2. Add the prepared binder into the kneader for heating and mixing until it melts (agglomerate), the speed of the kneader is 10-15r / min, and the set temperature is 150-170°C.

[0074]S3. Add the preheated metal powder into the melted binder to continue kneading, mix evenly, and keep the vacuum in the kneader. The speed of the mixer is 20-35r / min, the set temperature is 150-170°C, and the mixing time is 20-40min.

[0075] S4. Extrusion granulation: feeding the material processed in step S2 into an extruder, plasticizing, extruding, and granulating to obtain a powder injection molding feed.

[0076] S5. Using powder injection molding feedstock to perform injection molding, degreasing, and sintering MIM processes to obtain the product.

...

example 2

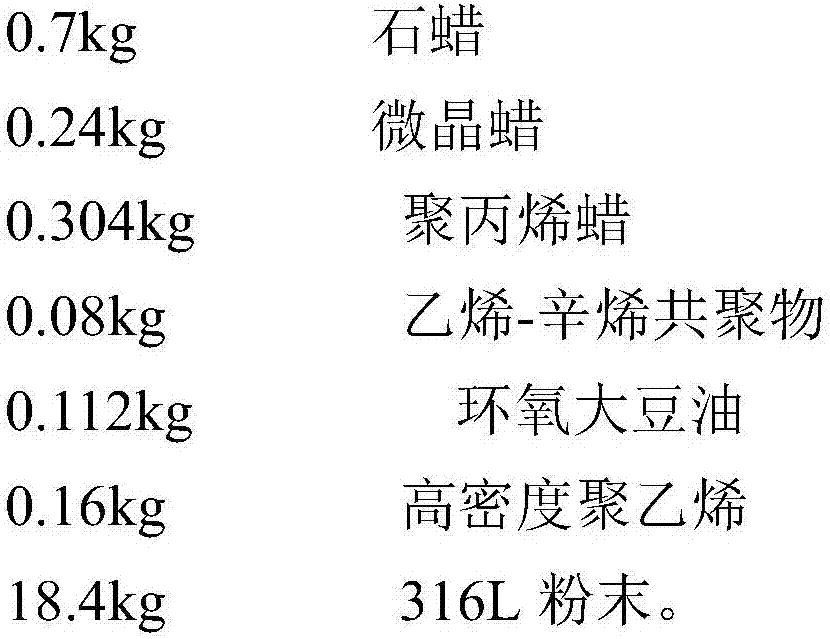

[0080] The feed consisted of the following components:

[0081]

[0082] The process of preparing the feed and using the feed to make MIM products is the same as Example 1.

[0083] Detect the performance of the feed: the melt index is 1700g / 10min.

[0084] The structure of the test product is complete, the appearance is good, and there are no defects such as black lines and lack of materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com