Regeneration treatment method and device of electronic waste plastic

A technology of electronic waste and treatment method, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problem of failure to realize efficient, economical and harmless sorting of electronic waste plastics, and the inability to realize efficient separation of electronic waste plastics Eliminate problems such as selection and low production efficiency, and achieve the effects of efficient and harmless recycling, low cost, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

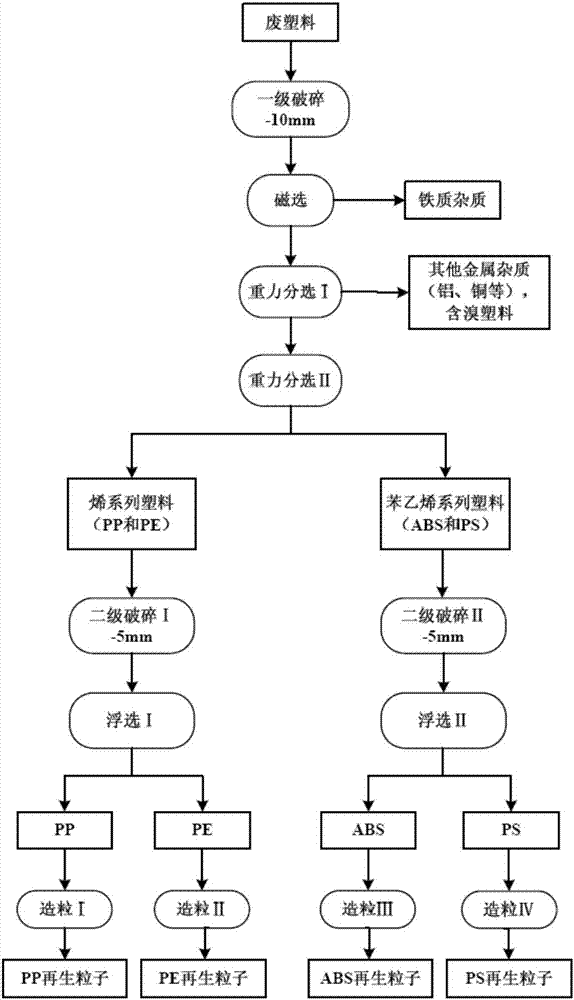

[0051] A recycling method for electronic waste plastics, such as figure 1 shown, including the following steps:

[0052] Step 1. Crushing and magnetic separation: Electronic waste plastics are crushed and electronic waste plastics with a particle size of less than 10 mm are selected for magnetic separation to separate magnetic metal materials from electronic waste plastics;

[0053] Step 2. Primary gravity separation: send the electronic waste plastics after magnetic separation to the cyclone for gravity separation, and separate the heavy component materials and light component materials, heavy component materials, non-magnetic metal materials and bromine-containing plastics; Light component materials are plastics with less metal impurities and bromine content,

[0054] Step 3. Secondary gravity separation: Send the light component materials into a cyclone or a clear water tank for secondary gravity separation to separate polyene plastics and styrene plastics;

[0055] Step ...

Embodiment 2

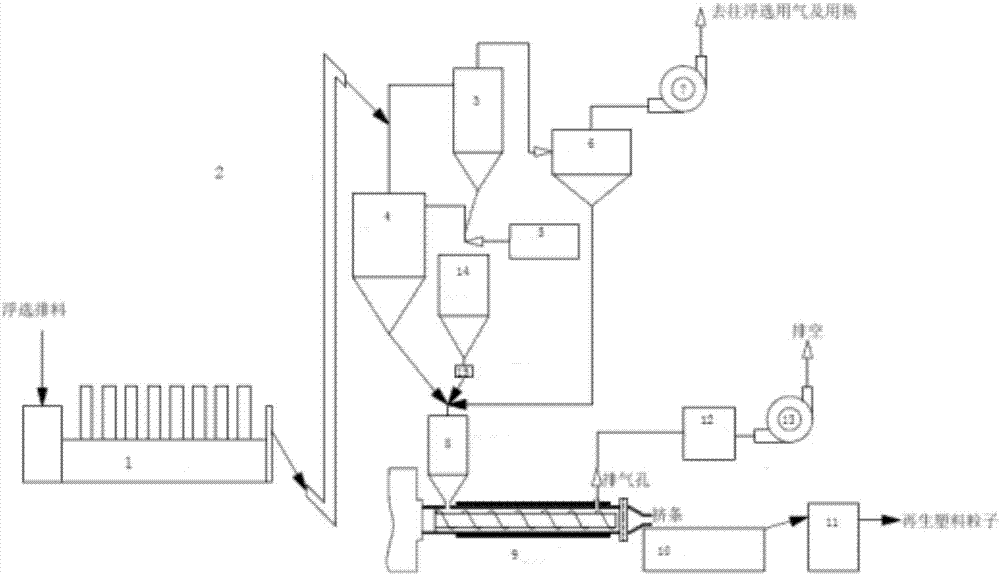

[0070] A regeneration treatment device for electronic waste plastics, such as figure 2 As shown, it includes primary crushing mechanism, magnetic separation mechanism, primary gravity separation mechanism (cyclone), secondary gravity separation mechanism (cyclone or clear water pool), secondary crushing mechanism, flotation mechanism, manufacturing The material is crushed by the primary crushing mechanism and sent to the magnetic separation mechanism for sorting. The magnetically separated material is sent to the primary gravity separation mechanism and the secondary gravity separation mechanism to obtain polyolefin plastics and benzene. Vinyl plastics are then sent to the secondary crushing mechanism for crushing, and then sent to the flotation mechanism for foam flotation, and the slurry obtained by flotation is sent to the granulation mechanism.

[0071] Both the primary crushing and the secondary crushing use plastic crushers, the particle size requirement of the primary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com