Pickling device for stones

A kind of pickling device and stone technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of over pickling of quartz sand, inability to produce quartz sand, insufficient removal of impurities from quartz sand, etc., and achieve the goal of accelerating pickling Speed, speed up processing efficiency, and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

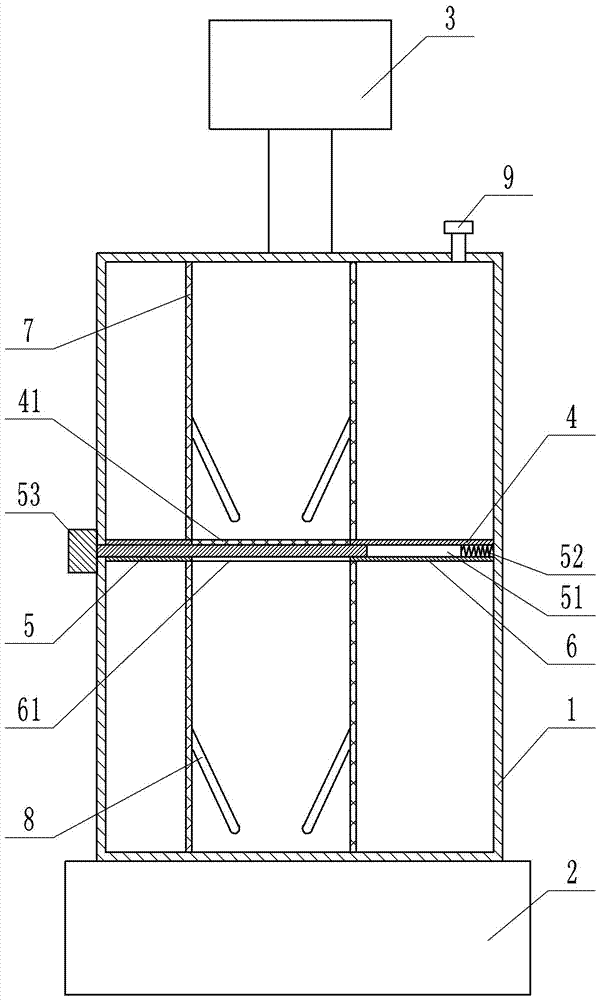

[0020] The reference signs in the drawings of the description include: sand washing cylinder 1, acid collection tank 2, motor 3, filter layer 4, screen hole 41, separation layer 5, through hole 51, spring 52, weight block 53, support layer 6, Opening 61, annular grid 7, stirring paddle 8, pressure relief valve 9.

[0021] Such as figure 1 As shown, a pickling device for stone includes a sand washing cylinder 1, an acid collection tank 2 and a motor 3 for driving the sand washing cylinder 1 to rotate horizontally. The motor 3 is electrically connected to a controller, and the controller can be obtained from the market Purchased directly from the Internet, the controller used in this example is the SDJ-3.5KW motor controller supplied by Fuzhou Xinlianda Technology. By setting the controller in advance, the motor 3 can be rotated at a fixed speed within a preset time perio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com