A method of using lignin-degrading bacteria to strengthen the hydrothermal pretreatment of waste biomass

A technology for lignin degrading bacteria and waste biomass, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to improve carbon source utilization and resource yield, increase accessible surface, and improve enzymatic hydrolysis efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) The rice straw was crushed and sieved with 60 meshes, washed twice with ultrapure water, and dried at 60°C until constant weight.

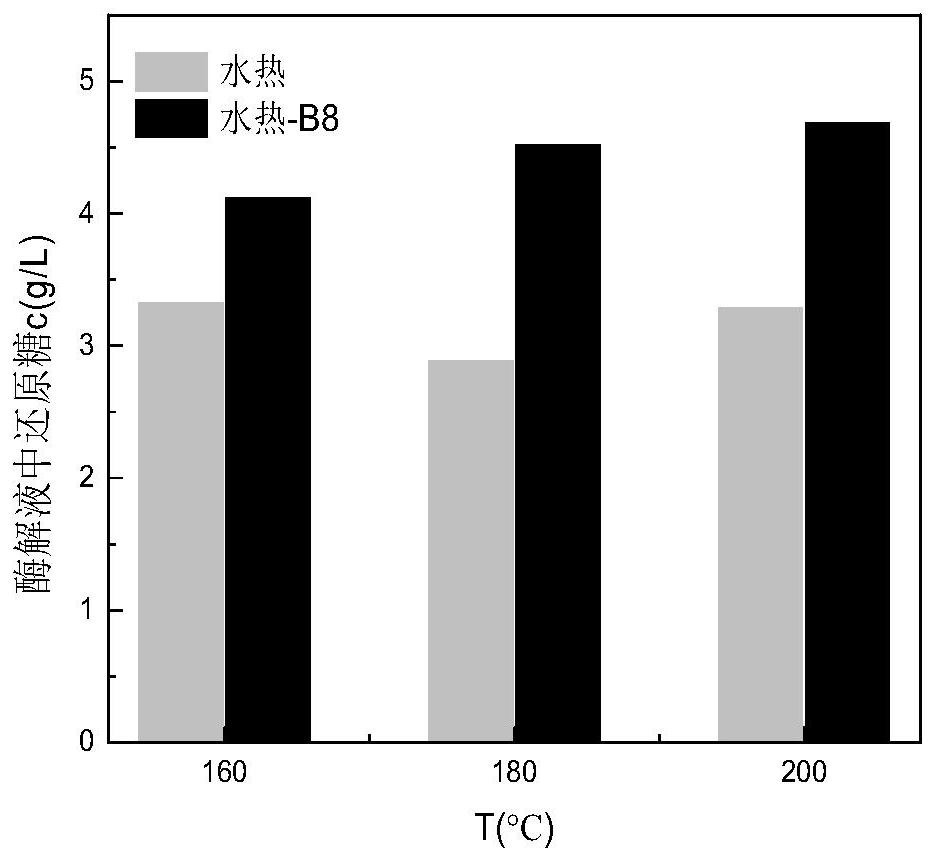

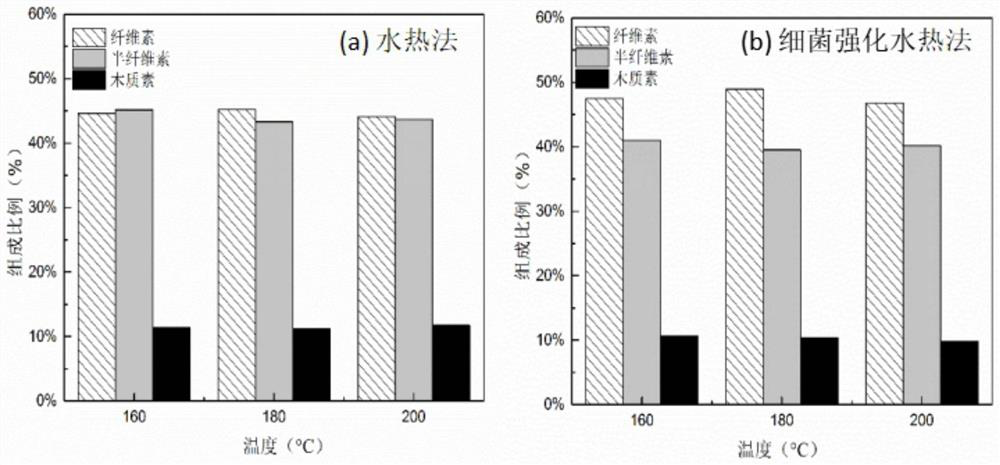

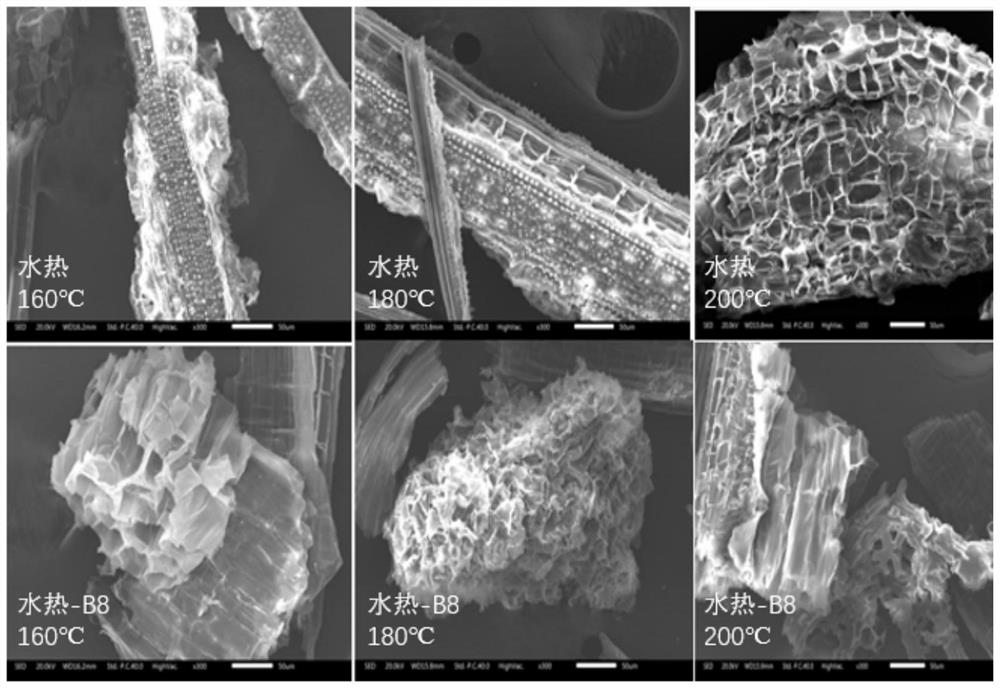

[0025] (2) Put the lignocellulose in a container of appropriate size, add ultrapure water according to the solid-liquid ratio of 1:10 (g / ml), and place it in a constant temperature environment of 160°C, 180°C, and 200°C for 30 minutes. , and the wet residue A was obtained by filtration and separation.

[0026] (3) Rinse the wet residue A obtained by filtering and separating with distilled water repeatedly until the pH of the washing liquid is neutral, and dry at 60° C. to a constant weight to obtain dry residue B.

[0027] (4) Inoculate the Cupriavidus basilensis B-8 bacterium stored in the refrigerator at -80°C in LB liquid medium, and culture it at 30°C for 18 hours (the optical density at 600nm reaches 0.8-1.0) to obtain Cupriavidus basilensis B- 8 seed liquid; wherein the LB liquid culture medium components ratio is: peptone 10g, y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com