Cleaning agent for engine die casting oil

A cleaning agent and engine technology, applied in the field of cleaning agents, can solve problems such as not being environmentally friendly, difficult to dispose of waste organic solvents, secondary pollution, etc., and achieve the effect of simple and environmentally friendly raw materials, good application prospects, and increasing the operating window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, and the contents of the examples are not intended to limit the protection scope of the present invention.

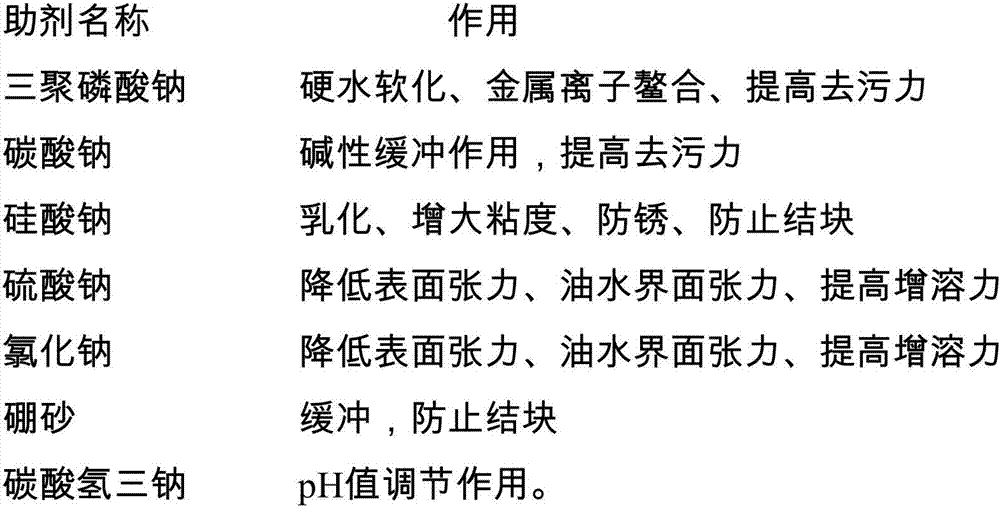

[0023] The invention relates to a cleaning agent for engine die-casting oil. Different from the existing organic solvent degreasing method, the invention adopts an alkaline degreasing method. Alkaline degreasing is a chemical cleaning method with alkaline substances as the main agent, mainly through saponification, emulsification, dispersion and dissolution to remove oil stains. The lye and saponifiable oil generate soluble fatty acid salt through saponification reaction, and for the unsaponifiable oil, the lye disperses the oil through the dissociation of the oil from the surface of the workpiece.

[0024] The alkaline degreasing method has good cleaning performance, less damage to the cleaned substrate, less usage, low price, no toxicity or low toxicity, no peculiar smell, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com