Method and device for determining safe charging condition of lithium ion battery

A technology for lithium-ion batteries and charging conditions, applied in battery circuit devices, secondary battery charging/discharging, circuit devices, etc., can solve problems such as misjudgment, large battery volume and capacity, and inability to judge visually. To achieve the effect of improving service life, safety performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

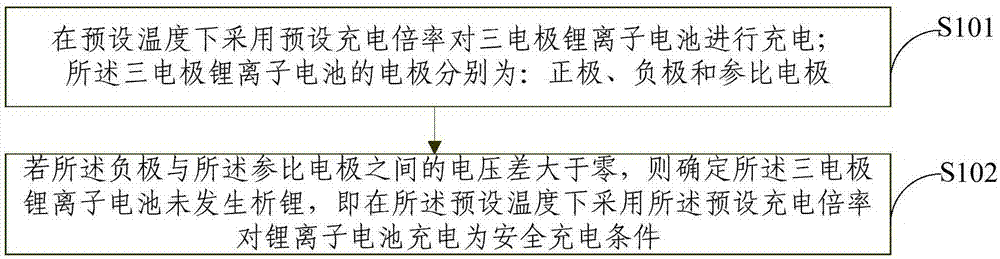

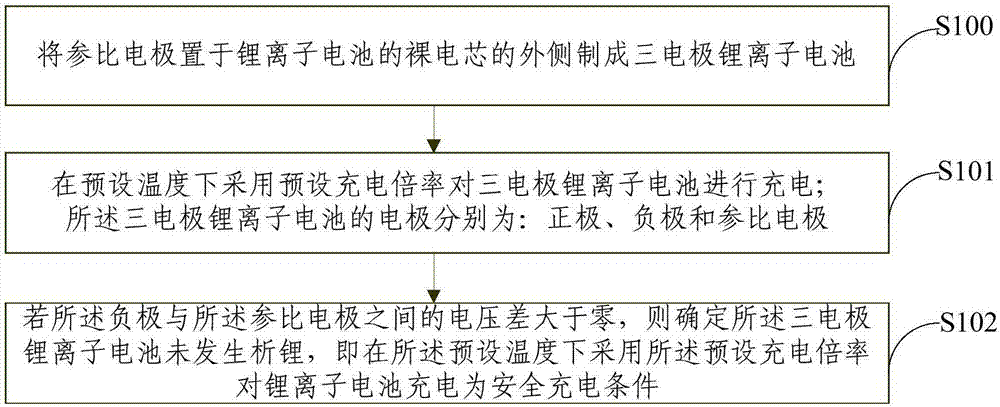

[0049] The method for determining lithium-ion safe charging condition is to realize according to the following steps:

[0050] 1) Prepare a three-electrode battery. The three-electrode battery has the same structure as the soft-packed lithium-ion battery to be confirmed, and has the same positive and negative electrodes. The reference electrode is a two-dimensional metal lithium sheet, and the reference electrode is placed on the outermost layer of the battery in the direction parallel to the electrode sheet;

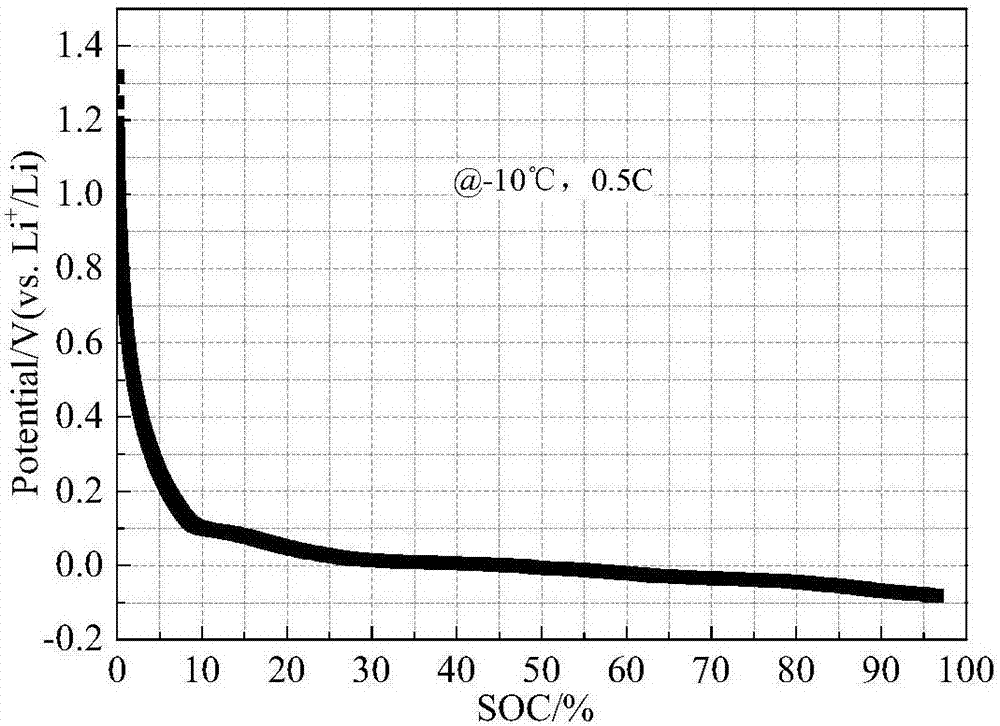

[0051] 2) Test the three-electrode battery, charge the battery at different temperatures and under different charging conditions, and judge whether the battery is decomposing lithium. Charge the battery with an electrochemical workstation, and record the voltage between the negative electrode and the reference electrode at the same time.

[0052] At -40°C, charge the battery at 0.1C, 0.2C, 0.5C, 1C, 2C, 5C, and 10C, and record the voltage between the negative electrode...

Embodiment 2

[0064] The method for determining lithium-ion safe charging condition is to realize according to the following steps:

[0065] 1) Prepare a three-electrode battery. The three-electrode battery has the same structure as the square lithium-ion battery to be confirmed, and has the same positive and negative electrodes. The reference electrode is a one-dimensional lithium-tin alloy wire, and the reference electrode is placed on the outermost layer of the battery parallel to the pole piece.

[0066] 2) Test the three-electrode battery, charge the battery at different temperatures and under different charging conditions, and judge whether the battery is decomposing lithium. Charge the battery with a charge-discharge tester, and simultaneously use a voltmeter to record the voltage between the negative electrode and the reference electrode.

[0067] At -30°C, charge the battery at 0.1C, 0.2C, 0.5C, 1C, 2C, 5C, and 10C, and record the voltage between the negative electrode and the ref...

Embodiment 3

[0077] The method for determining lithium-ion safe charging condition is to realize according to the following steps:

[0078] 1) Prepare a three-electrode battery. The three-electrode battery has the same structure as the soft-pack lithium-ion battery to be confirmed, and has the same positive and negative electrodes. The reference electrode is a one-dimensional lithium-copper alloy rod, and the reference electrode is placed on the outermost layer of the battery in the vertical direction of the pole piece.

[0079] 2) Test the three-electrode battery, charge the battery at different temperatures and under different charging conditions, and judge whether the battery is decomposing lithium. Charge the battery with a charge-discharge tester, and at the same time record the voltage between the negative electrode and the reference electrode with a multimeter.

[0080] At -40°C, charge the battery at 0.1C, 0.2C, 0.5C, 1C, 2C, and 5C respectively and record the voltage between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com