Heat radiating method of radiator for communication equipment

A heat dissipation method and technology of a heat dissipation device, which are applied in the direction of temperature control using digital devices, measuring devices, and structural parts of electrical equipment, etc., which can solve the problem of low heat dissipation efficiency, failure to meet the heat dissipation requirements of communication equipment, and the inability to install high-power heat dissipation and cooling Device and other issues, to achieve reliable heat dissipation, maximize heat exchange efficiency, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

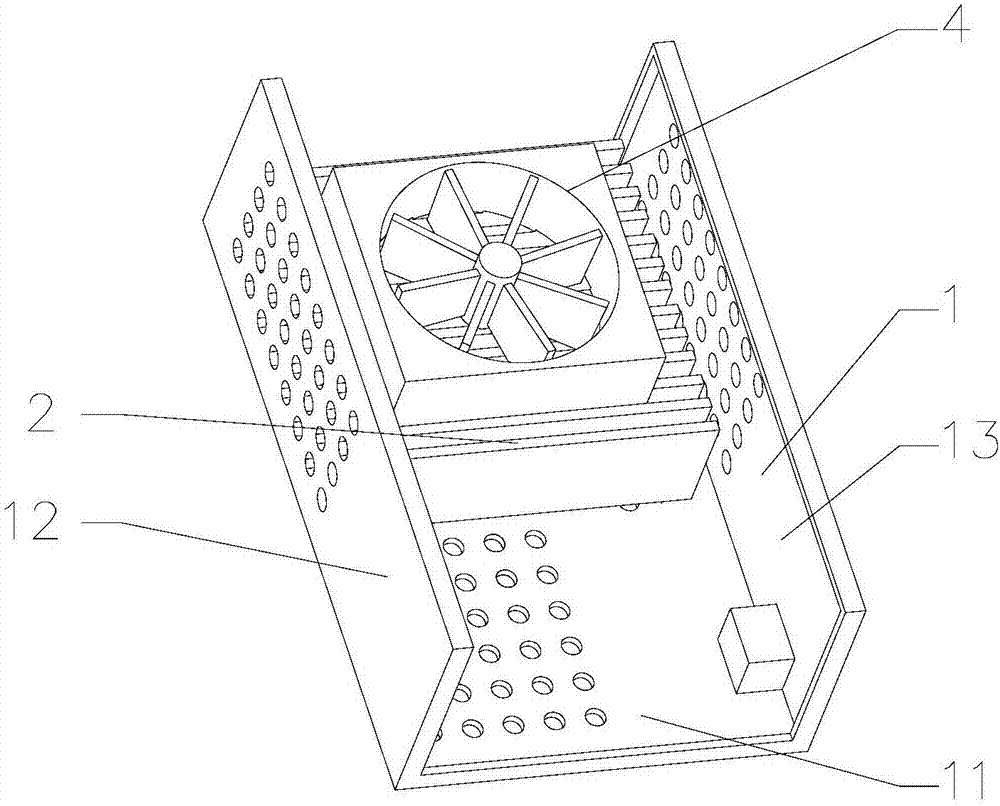

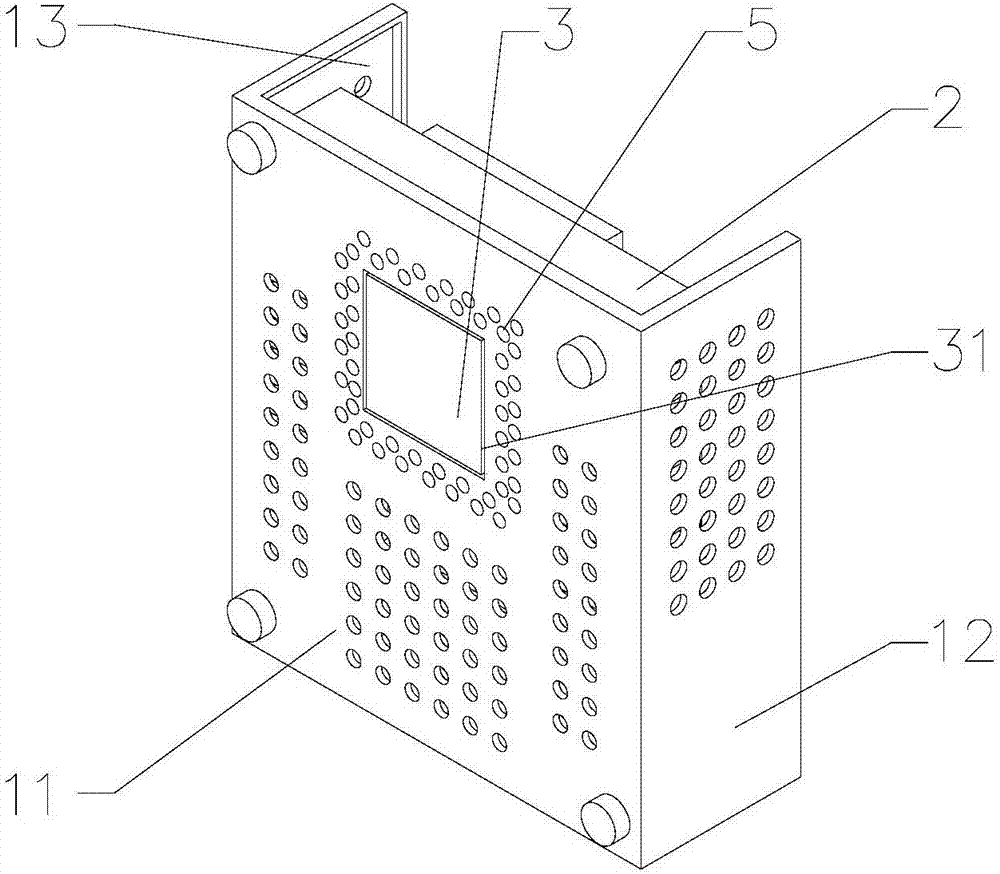

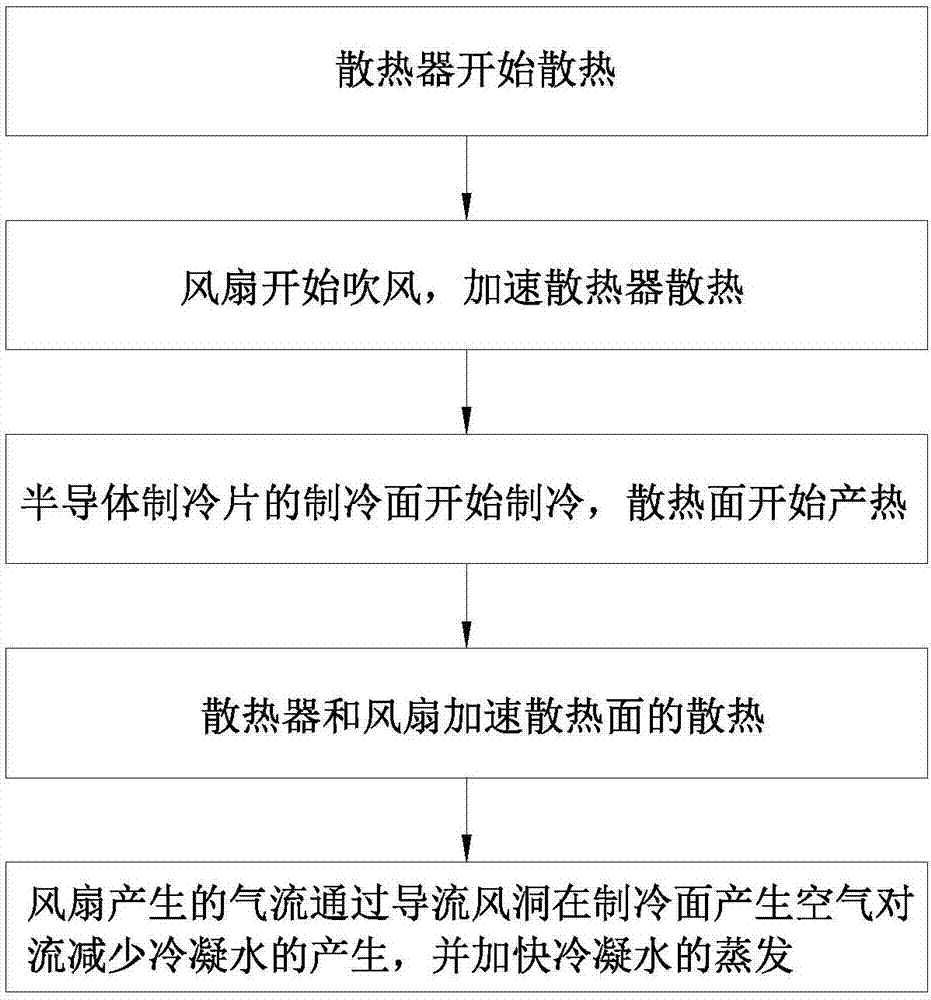

[0040] Such as Figures 1 to 3As shown, the present invention provides a heat dissipation method for a heat dissipation device of communication equipment. The heat dissipation device includes a housing 1, a radiator 2, a semiconductor cooling chip 3 and a fan 4. The semiconductor cooling chip 3 has low power consumption and low noise. It is reliable in use and is very suitable for narrow spaces. The semiconductor cooling chip 3 includes a cooling surface 31 and a heat dissipation surface 32. Both the cooling surface 31 and the heat dissipation surface 32 are coated with heat-conducting silicone grease. The housing 1 includes a main end surface 11, a first end surface 12 and The second end face 13, the first end face 12 and the second end face 13 are arranged on the two ends of the main end face 11, the main end face 11 and the first end face 12, the second end face 13 are integrally arranged and are "Π" type, and the semiconductor refrigeration sheet 3 is inlaid On the main en...

Embodiment 2

[0047] Such as Figures 4 to 6 As shown, the main difference between this embodiment and Embodiment 1 is that this embodiment adds a temperature detection step, a temperature display step and a setting step.

[0048] The heat dissipation device also includes a temperature controller 6 and an LED display 7. The temperature controller 6 includes a temperature control probe 61, an MCU and a setting button 62. The temperature control probe 61 is provided with a temperature sensor for measuring the surface temperature of the communication device. The temperature control probe 61 is connected with MCU by wire, MCU is connected with semiconductor refrigeration sheet 3 by wire, preset temperature is set in MCU, setting button 63 is connected with MCU by wire and can set preset temperature, LED display 7 and MCU are connected by wire It is connected and can display the surface temperature of communication equipment in real time.

[0049] The cooling method of this embodiment includes ...

Embodiment 3

[0057] Such as Figure 7 As shown, the main difference between the present embodiment and the second embodiment is that an adjustment step is added in the present embodiment.

[0058] The heat dissipation device also includes a regulating switch, and the regulating switch is connected with the semiconductor refrigeration sheet through wires.

[0059] The cooling method of this embodiment includes the following steps:

[0060] Preliminary heat dissipation steps: the radiator starts to work, the radiator dissipates the heat transferred from the communication equipment, the fan starts to work, and the fan provides sufficient airflow to the radiator to form air convection around the radiator to speed up the heat dissipation of the radiator.

[0061] Adjustment step: adjust the cooling power of the semiconductor refrigeration sheet in the cooling step by adjusting the switch. This step enables the cooling power of the semiconductor refrigerating sheet to be adjusted according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com