A continuous and rapid production process of edible mushroom sticks

A production process and technology of edible fungi, applied in application, horticulture, fungi, etc., can solve the problems of insufficient oxygen flow and poor quality of mushrooms, and achieve good sterilization effect, short cooling time and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

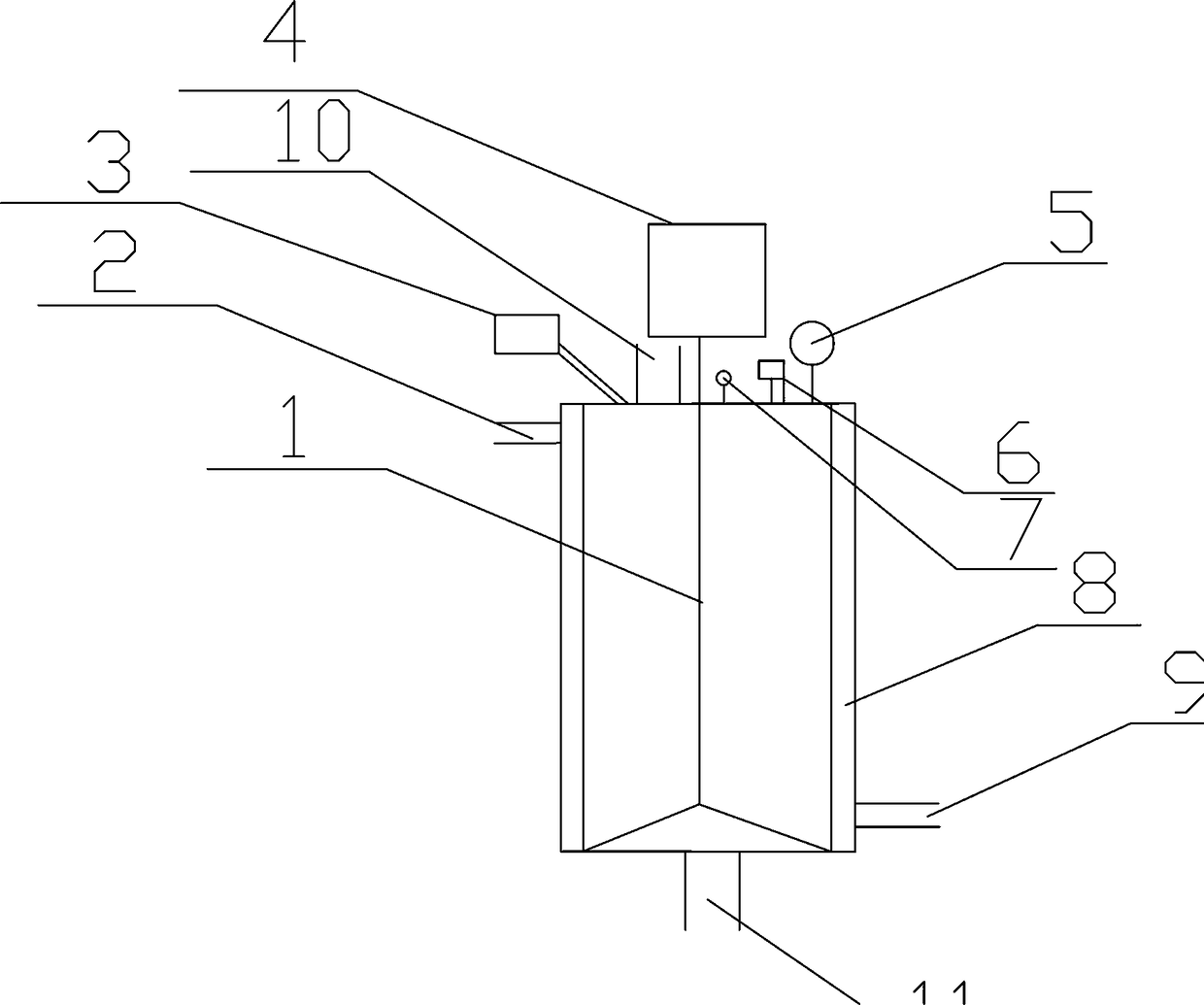

[0020] Such as figure 1 As shown, a continuous rapid production process of edible mushroom sticks includes the following steps: (1) fermentation of raw materials; (2) sterilization of bulk materials; (3) aseptic cooling; (4) liquid seed production; (6) Aseptic bagging; (7) Full oxygen culture.

[0021] Preferably, the raw material fermentation step is: add water to the crop waste particles until the water content reaches 60%-65%, and accumulate them into a ladder-like structure. 2-3 meters, 1-1.8 meters high; make a ventilation hole every 0.3-0.6 meters from top to bottom, and the material surface is covered with a sunshade net to breathe and moisturize; when the temperature reaches 65 degrees at a depth of 0.2 meters from the material surface, start timing After 6-8 hours, turn the pile. The principle of turning the pile is to reverse the inside and outside. When the temperature reaches 65 degrees at 0.2 meters inward of the material surface, the fermentation ends after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com