Edible fungus and pickled vegetable product fermented by directly adding lactobacillus and preparation method thereof

A technology of edible fungi and lactic acid bacteria, applied to bacteria, lactobacillus, food preservation and other directions used in food preparation, can solve the problems that the literature research on straw mushroom kimchi has not been reported, and achieve the effect of unique flavor, simple process and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

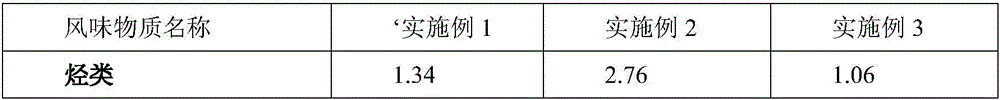

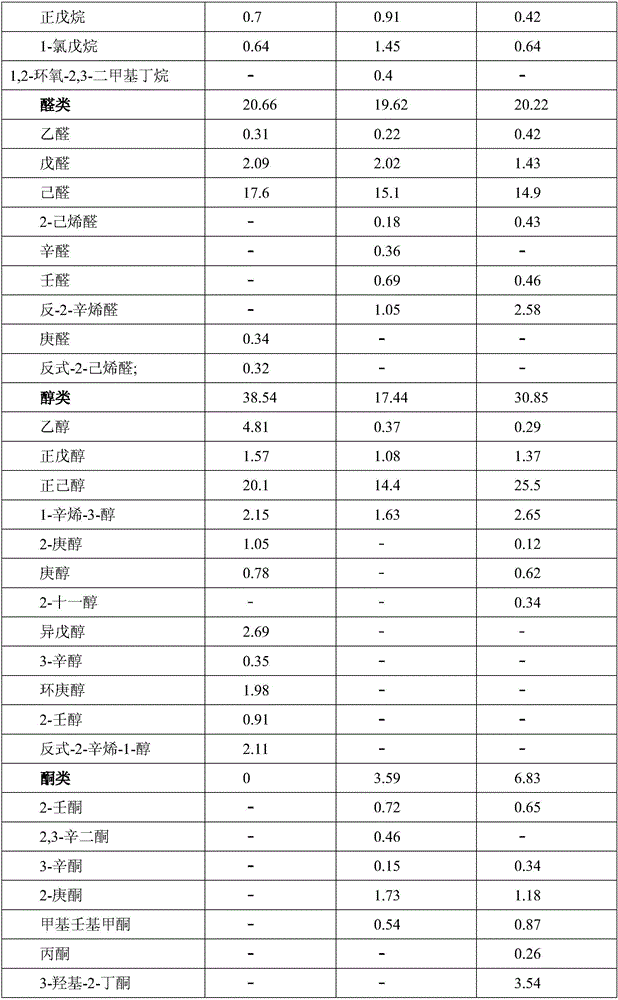

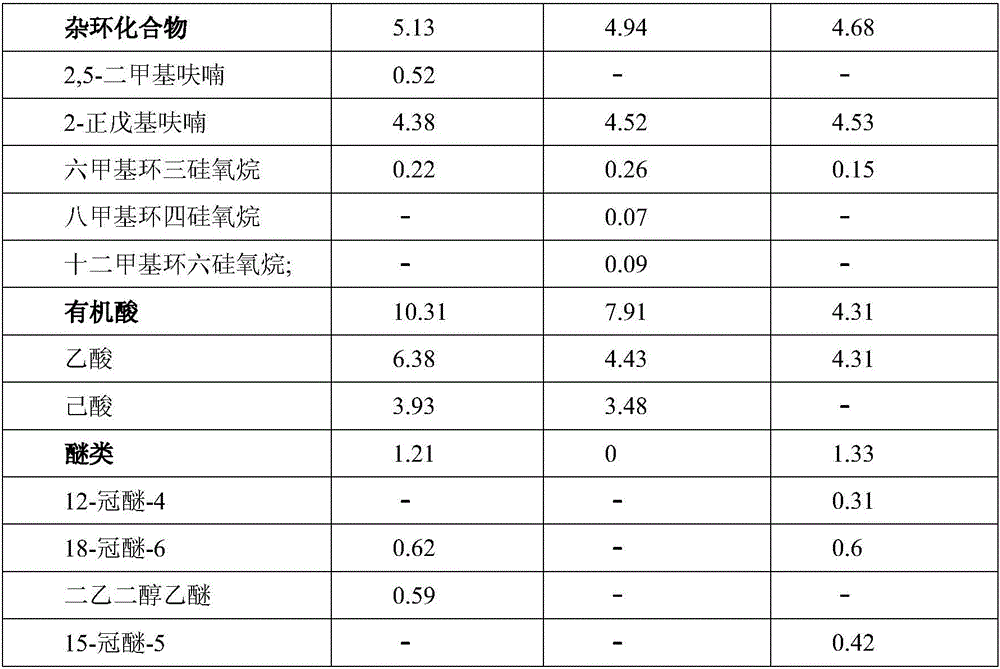

Embodiment 1

[0021] Embodiment 1: Straw mushroom kimchi products of the present invention are made from straw mushrooms, salt, white sugar, water and a leavening agent, wherein, the straw mushrooms, water, salt and white sugar are calculated in parts by weight: Straw mushrooms 2000 parts, 1000 parts of water, 40 parts of salt, 20 parts of white sugar.

[0022] The starter is Lb breve Lactobacillus plantarum, and the amount added reaches 10% according to the thalline content in the solution. 8 -10 9 cfu / ml meter. Specifically, the Lb breve plantarum Lactobacillus purchased in the China Industrial Microbial Culture Collection Center is activated, centrifuged, etc. according to the following steps: Lb breve Lactobacillus plantarum is mixed with a volume ratio of 1:10 (that is, Lb breve Lactobacillus plantarum and liquid The volume ratio of the MRS medium is 1:10) and inoculated in the liquid MRS medium for the first activation, the activation time is 16 hours, and the activation temperature...

Embodiment 2

[0030] Embodiment 2: leavening agent is Lp lactobacillus plantarum, and addition amount reaches 10 by the thalline content in the solution 8 -10 9cfu / ml meter. Specifically, the Lp Lactobacillus plantarum of the Applied Biotechnology Laboratory of Jiangsu University was activated and centrifuged according to the following steps: the Lp Lactobacillus plantarum was inoculated in the liquid MRS medium at a volume ratio of 1:10 for the first activation, and the activated The time is 10 hours, and the activation temperature is 37°C. Then inoculate the first-activated bacterial solution in the liquid MRS medium at a volume ratio of 1:5 for the first activation. The activation time is 14 hours and the activation temperature is 37°C. After secondary activation, the strain was centrifuged in a low-speed centrifuge at a speed of 5000r / min for 15 minutes, the supernatant was discarded, and the white precipitate in the lower layer was washed with sterilized water for 2 to 3 times. The ...

Embodiment 3

[0031] Embodiment 3: leavening agent is L 3 and L 19 Composite Lactobacillus plantarum, the amount added is 10% according to the bacterial content in the solution 8 -10 9 cfu / ml meter. Specifically, L of the Applied Biotechnology Laboratory of Jiangsu University 3 and L 19 Lactobacillus plantarum was activated and centrifuged according to the following steps: inoculated in liquid MRS medium at a volume ratio of 1:10 for the first activation, the activation time was 10 hours, and the activation temperature was 37°C. Then inoculate the first-activated bacterial solution in the liquid MRS medium at a volume ratio of 1:5 for the first activation. The activation time is 14 hours and the activation temperature is 37°C. After secondary activation, the strain was centrifuged in a low-speed centrifuge at a speed of 5000r / min for 15 minutes, the supernatant was discarded, and the white precipitate in the lower layer was washed with sterilized water for 2 to 3 times. starter L 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com