Synthetic method of aminated mesoporous silicon dioxide for modified cyanate ester resin

A cyanate ester resin and aminated mesoporous technology, which is applied in the field of base materials for high-frequency printed boards, can solve the problems of reducing the mechanical properties and thermal properties of polymers, save materials and energy, have broad market prospects, and a preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The synthetic method of the aminated mesoporous silica for modified cyanate resin of the present embodiment comprises the steps:

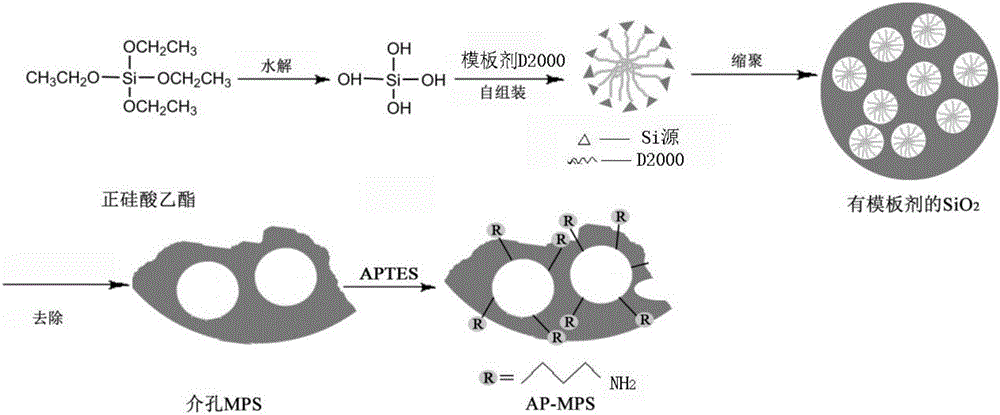

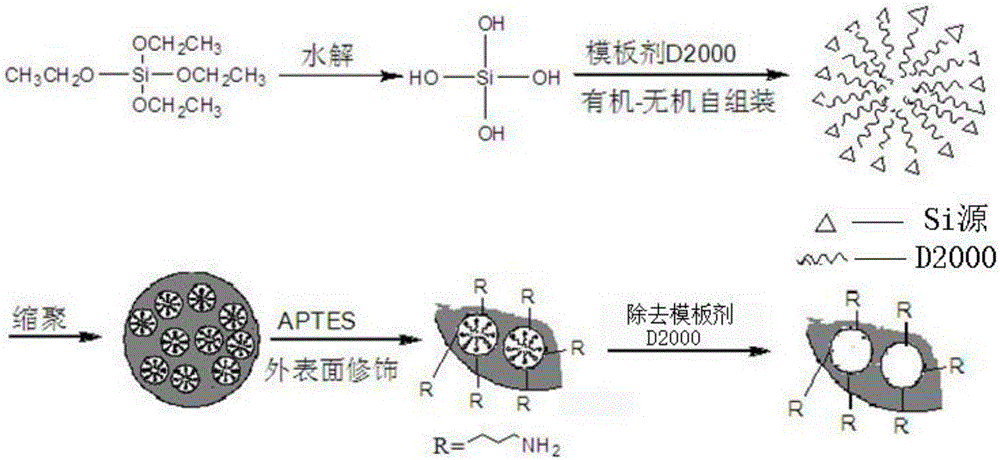

[0053] Step 1: Roasting (flow chart as figure 1 shown)

[0054] Step (1.1): Dissolve the template agent D2000 in ethanol, add deionized water, and stir at a constant temperature of 25°C for 1 hour, then add TEOS, and continue to stir with a magnetic stirrer for 30 minutes after mixing. The TEOS, template agent D2000 , The molar ratio of deionized water and ethanol is 1.0:0.125:220:17, then shake and stir in a constant temperature hot water bath at 25°C for 20h, cool to room temperature at 25°C, pass through a 60-mesh sieve, wash with water, and use electric heating to blow Dried in a drying oven at 70°C and crushed to 1 μm to obtain MPS, which was evenly divided into two equal parts;

[0055] Step (1.2): Calcining an aliquot of MPS obtained in step (1.1) in a muffle furnace for 5 hours to obtain calcined C-MPS;

[0056] Step (1.3): Mix th...

Embodiment 2

[0065] The synthetic method of the aminated mesoporous silica for modified cyanate resin of the present embodiment comprises the steps:

[0066] Step 1: Roasting (flow chart as figure 1 shown)

[0067] Step (1.1): Dissolve the template agent D2000 in ethanol, add deionized water, and stir at a constant temperature of 20°C for 30 minutes, then add TEOS, and continue stirring with a magnetic stirrer for 40 minutes after mixing. The TEOS, template agent D2000 , The molar ratio of deionized water and ethanol is 0.6:0.08:170:15, then shake and stir in a constant temperature hot water bath at 45°C for 17h, cool to room temperature at 28°C, pass through a 70-mesh sieve, wash with water, and use electric heating to blow Dried in a drying oven at 85°C and crushed to 5mm to obtain MPS, which was evenly divided into two equal parts;

[0068] Step (1.2): Calcining an aliquot of MPS obtained in step (1.1) in a muffle furnace for 4 hours to obtain calcined C-MPS;

[0069] Step (1.3): Mix...

Embodiment 3

[0078] The synthetic method of the aminated mesoporous silica for modified cyanate resin of the present embodiment comprises the steps:

[0079] Step 1: Roasting (flow chart as figure 1 shown)

[0080]Step (1.1): Dissolve the template agent D2000 in ethanol, add deionized water, and stir at a constant temperature at 40°C for 2 hours, then add TEOS, and continue to stir with a magnetic stirrer for 1 hour after mixing. The TEOS, template agent D2000 , The molar ratio of deionized water and ethanol is 1.5:0.13:240:20, then shake and stir in a constant temperature hot water bath at 65°C for 25 hours, cool to room temperature at 30°C, pass through a 80-mesh sieve, wash with water, and use electric heating to blow Dried in a drying oven at 100°C and crushed to 10mm to obtain MPS, which was evenly divided into two equal parts;

[0081] Step (1.2): Calcining an aliquot of MPS obtained in step (1.1) in a muffle furnace for 6 hours to obtain calcined C-MPS;

[0082] Step (1.3): Mix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com