Construction site drainage method using water collecting well

A technology for construction sites and water collection wells, applied in water conservancy projects, drainage structures, artificial islands, etc., can solve problems such as unfavorable construction site standardization management and civilized construction requirements, unfavorable construction cost savings, and inability to reuse, etc. Drainage problems, ensuring smooth drainage, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The construction site drainage method using the water collection well of the present invention comprises the following steps:

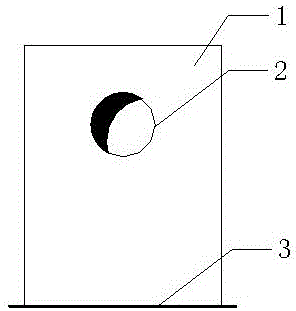

[0031] see now figure 1 , figure 1 It is a schematic diagram of the structure of the water collection well in the embodiment of the present invention.

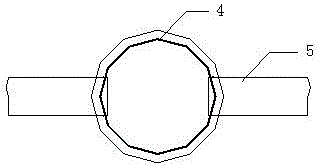

[0032] a. Set up the drainage steel pipe 5 pipeline: use the construction waste steel pipe DN300*4mm as the drainage pipeline, and the joints of the steel pipe pipeline shall be welded.

[0033] b. Make the water collection well: use a large-diameter pipe DN1000*8mm, cut a section of 1.8m long as the wall of the water collection well, and cut a circular steel plate with a diameter 100mm larger than the large-diameter pipe DN1000 and a thickness of 8mm as the bottom plate of the water collection well. Weld the steel plate bottom plate and the steel pipe well wall, and cut a hole with a diameter 5-8mm larger than the outer diameter of the drainage pipe by gas cutting or plasma cutting at 500mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com