Correlation model algorithm for downhole corrosion rate at wellhead and online monitoring method for downhole corrosion rate using this algorithm

A technology of corrosion rate and correlation model, which is applied in the field of online monitoring of downhole corrosion rate and correlation model algorithm of downhole corrosion rate at the wellhead, can solve the problems of inability to reflect the corrosion process data, large error of test results, long test period, etc., and achieve good promotion and application Prospects, the effect of avoiding safety accidents and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Correlation model algorithm of downhole corrosion rate at wellhead and online monitoring method of downhole corrosion rate using this algorithm.

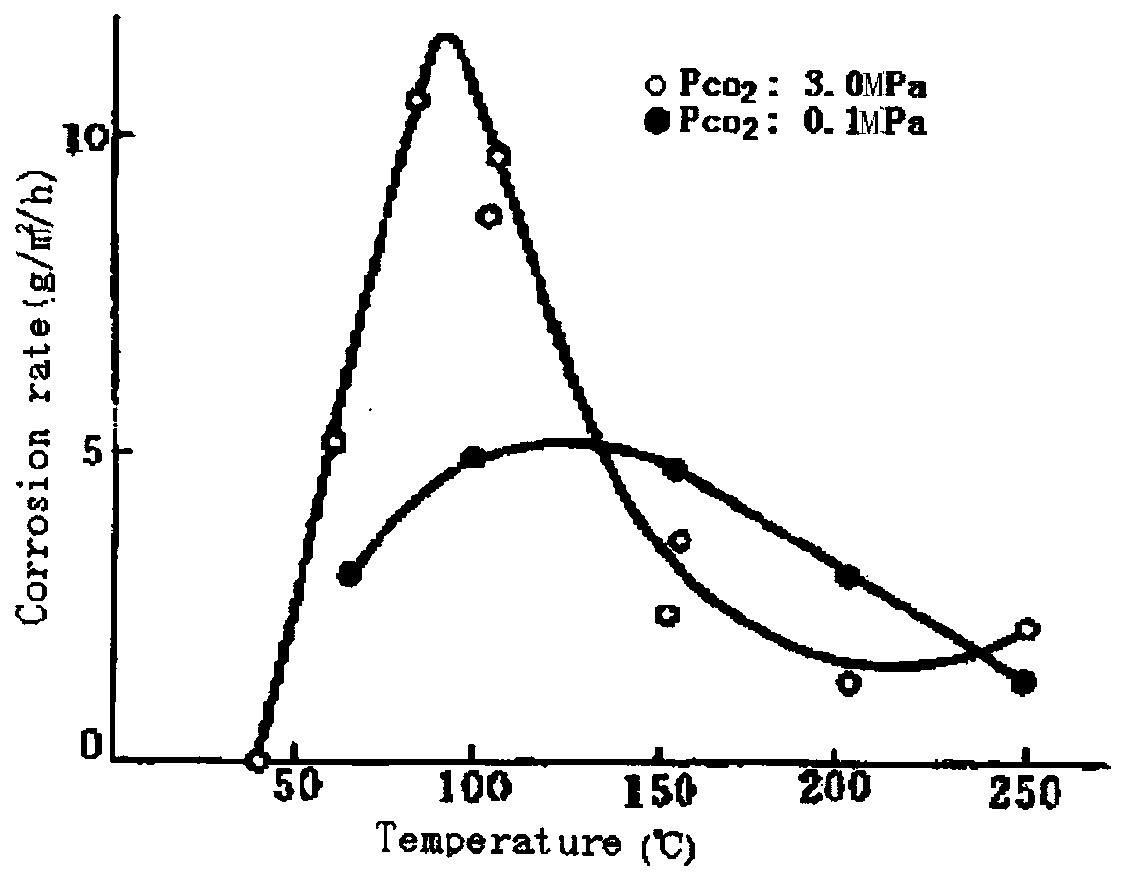

[0067] (2) CO 2 Research on the law of flooding and corrosion:

[0068] 1. Steel material for corrosion test:

[0069] In the corrosion experiment, the materials of the inductance probe and the coupon are all common steels for oil field oil casing, including J55, N80 and A3 steels. The chemical composition of each steel is analyzed as follows:

[0070] The chemical composition of A3 steel in the experiment is shown in Table 2-1:

[0071] Table 2-1 Chemical composition (%) of A3 steel used in experiments

[0072]

[0073] The chemical composition of N80 steel used in the experiment is shown in Table 2-2:

[0074] Table 2-2 The chemical composition (%) of N80 steel used in the experiment

[0075]

[0076] The chemical composition of J55 steel used in the experiment is shown in Table 2-3:

[0077] Table 2-3 The ...

Embodiment 2

[0237] Embodiment 2, research on correlation between wellhead and downhole corrosion rate:

[0238] Since a large number of downhole corrosion rate tests have been carried out above, two technical routes are proposed for the prediction of downhole corrosion conditions, and the technical advantages and disadvantages are finally determined through laboratory and field verification.

[0239] Technical route 1: Figure 15 through the existing CO 2 The screening and correction of the prediction model directly predicts the corrosion rate at the wellhead and downhole. If a correlation can be established through a certain corrosion influencing factor, such as salinity, the research purpose is achieved. If it cannot be correlated, the corrosion influencing factor can also be directly applied Correlation data for direct prediction of corrosion.

[0240] Technical route 2: To avoid the influence of various influencing factors on the downhole corrosion rate, directly measure the downhol...

Embodiment 3

[0361] Example 3. Application examples from here on.

[0362] CO 2 Research on application of flooding online corrosion monitoring system.

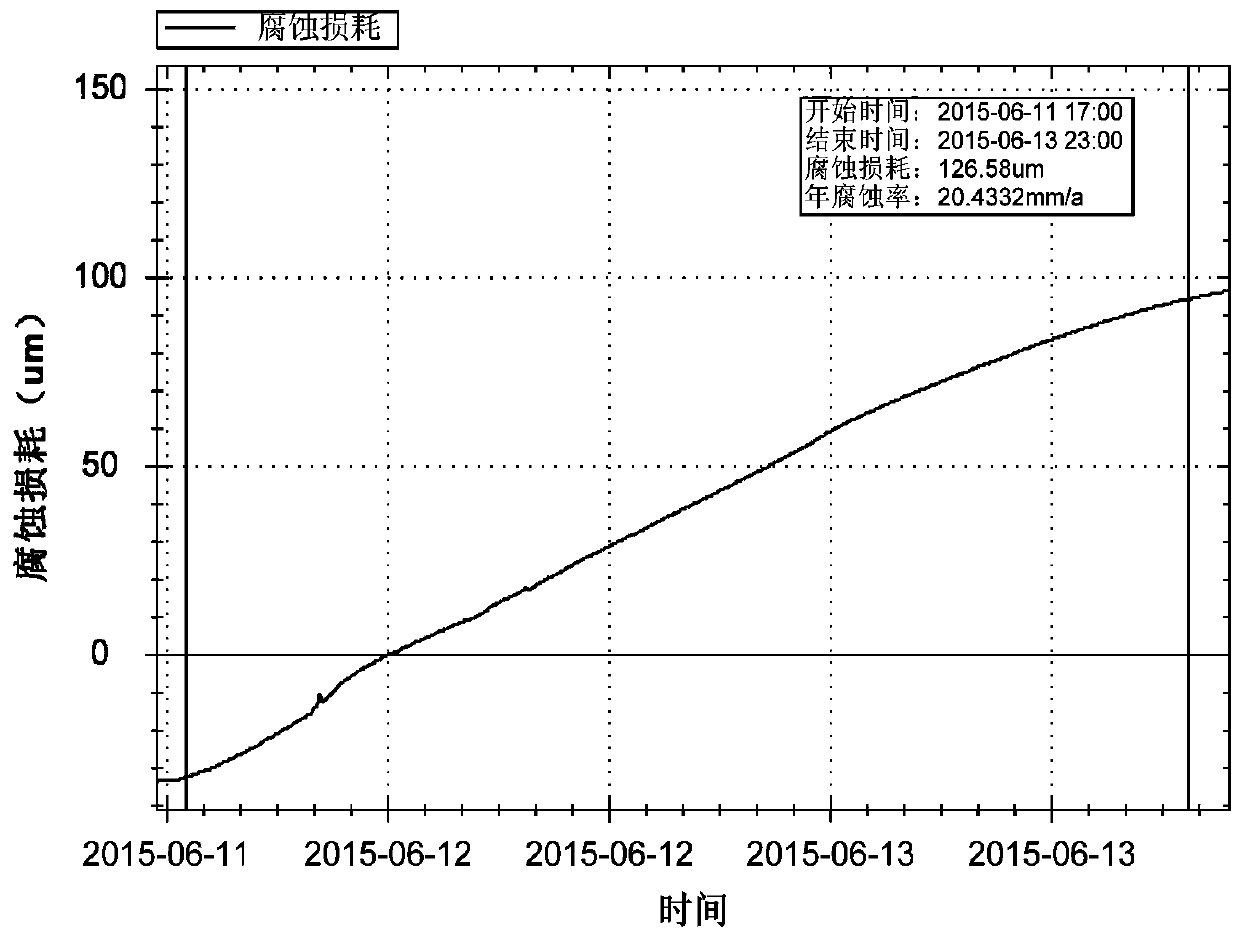

[0363] 1. Research on the application of corrosion monitoring in the 1# experimental well of Binnan No. 1 Coal Mine.

[0364] The test start time of 1# test well was December 7, 2015.

[0365] (1) Installation of wellhead monitoring equipment and data analysis.

[0366] The on-site working conditions of the 1# experimental well of Binnan No. 1 Coal Mine are (December 2015):

[0367] Wellhead temperature: 18°C, total wellhead pressure: 0.5Mpa, sucker rod stroke: 3m, sucker rod stroke times: 4, daily liquid production: 31.8t, daily water production: 27t, crude oil water content: 85%.

[0368] The liquid and gas sampling and analysis data of the produced fluid of the 1# test well are as follows (analysis time: December 23, 2015).

[0369] Table 3-1 Gas analysis results of produced fluid in 1# test well

[0370]

[0371] Table 3-2 Li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com