Magneto resistance sensor-based magnetic conductivity electromagnetic tomography system

An electromagnetic tomography, magnetoresistive sensor technology, applied in the direction of magnetic performance measurement, permeability measurement, material magnetic variables, etc., can solve the problems of secondary field strength, EMT detection accuracy limit, limited application and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

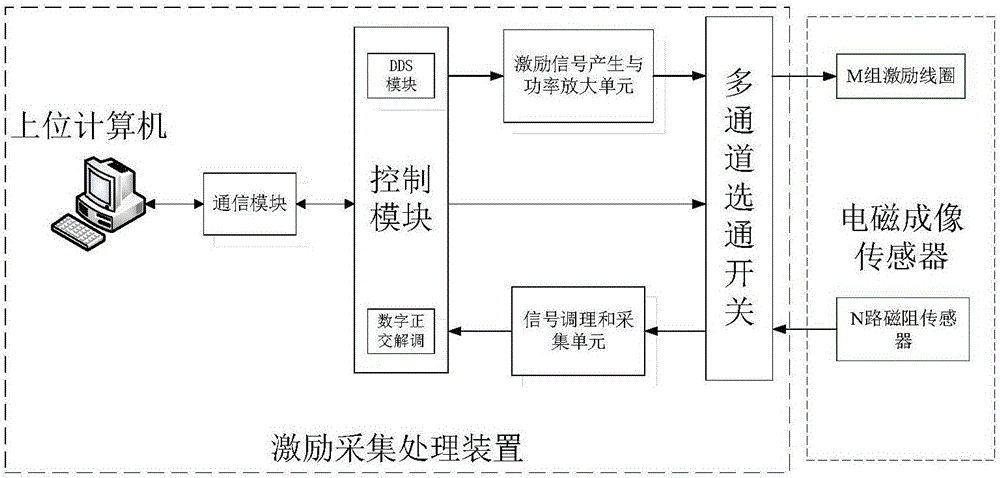

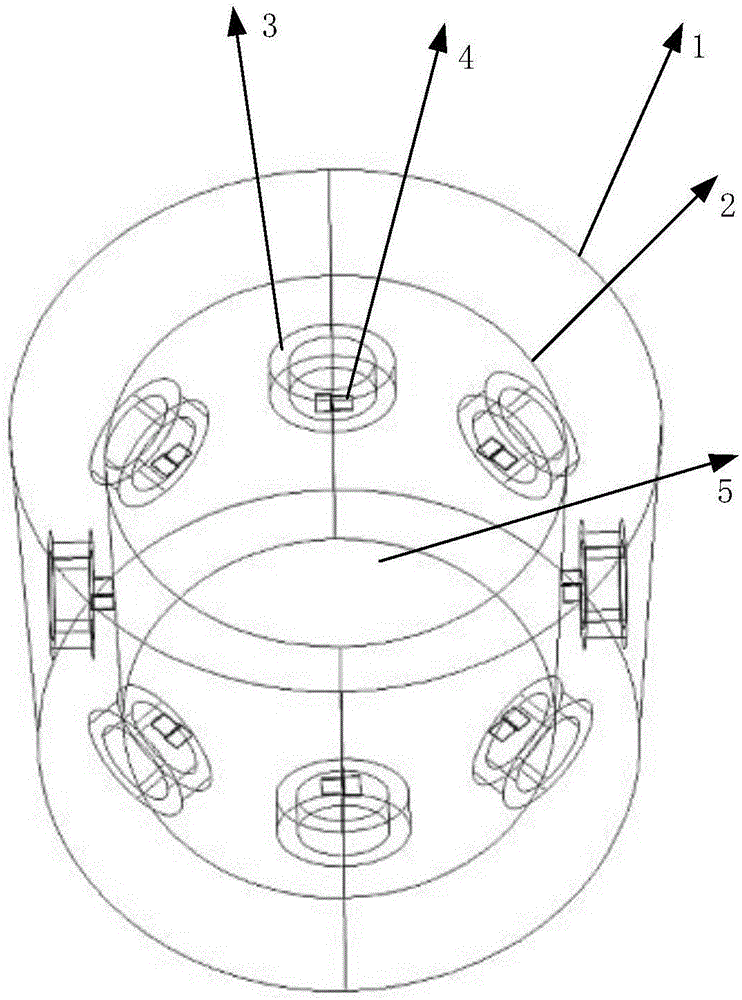

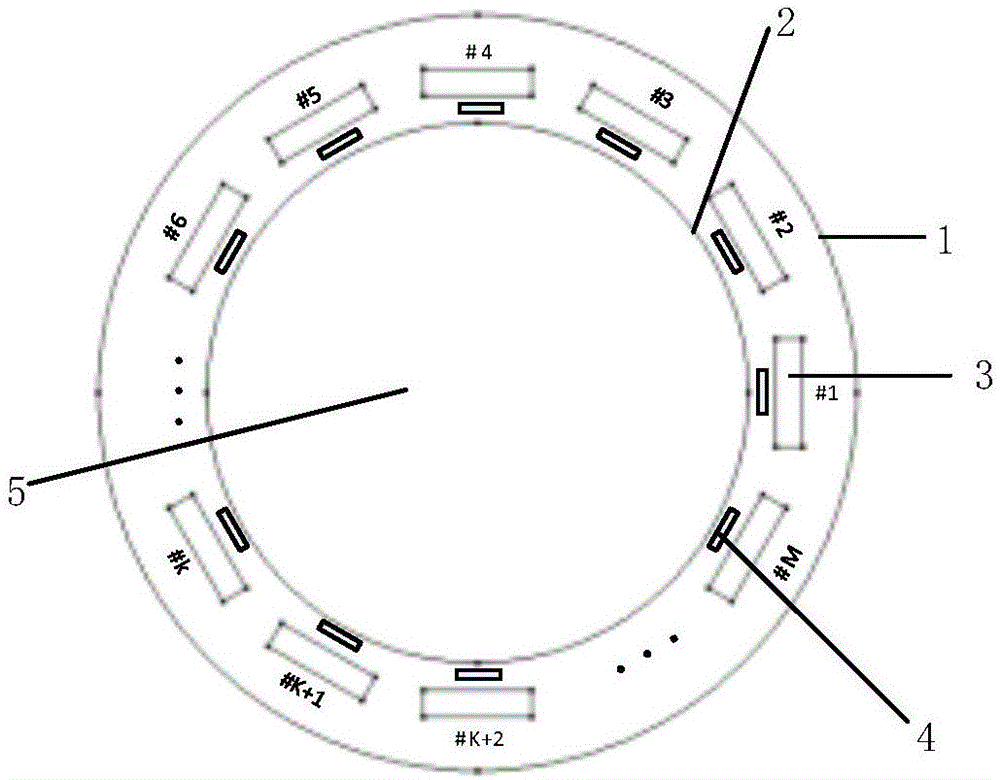

[0019] The invention introduces and designs a fluidized electromagnetic tomography magnetoresistive sensor array, which can obtain the magnetic permeability distribution by directly detecting the magnetic field through the magnetic resistance, and realize the measurement of the magnetic permeability distribution parameters and the magnetic permeability imaging. Magnetoresistive sensor, the detection sensitivity is not affected by the frequency of the excitation magnetic field, which greatly improves the scope of application. At the same time, it is favored by more and more people because of its advantages of high sensitivity, good reliability, wide measurement range, resistance to harsh environments, and small size. . This system introduces a magnetoresistive sensor, due to its small size, generally within 5mm, it can realize the direct detection of the radial and tangential directions of the magnetic field, increase the number of detection points, improve the detection sensiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com