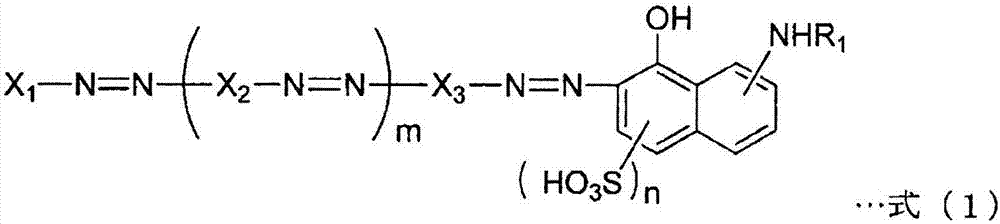

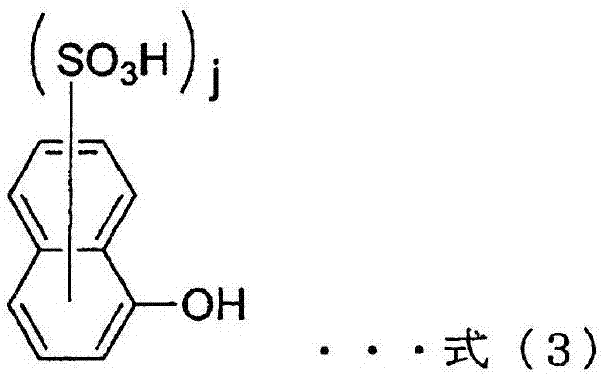

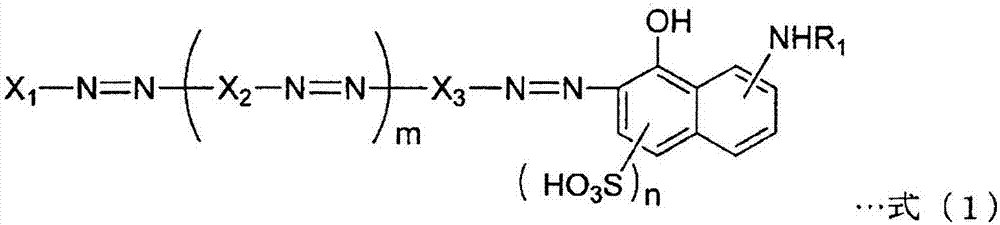

Polarizing element formed by stacking film having high retardation and layer containing dichroic dye, and display device provided with same

A technology of dichroic pigments and polarizing elements, applied in polarizing elements, optical elements, optical elements, etc., can solve the problems that the practical level of polarization performance of polarizing elements cannot fully meet the requirements, and achieve the effect of excellent polarization performance and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] On the non-adhesion-treated surface of a stretched film (Cosmoshine SRF film manufactured by Toyobo Co., Ltd.) with a retardation of 10500 nm and a thickness of 100 μm, a glass rod provided with a distance of 3 μm from the stretched film was used. Coating machine, coated with 0.15 parts by mass of C.I. Direct Blue 67 4 parts by mass as a dichroic pigment, 0.15 parts by mass of polyoxyethylene polyoxypropylene alkyl ether (Emulgen MS-110 manufactured by Kao Corporation), and 100 parts by mass of water. solution. The obtained coating film was left to stand in an environment of 25 degreeC and 70% of humidity for 1 minute, and the solvent was dried. Furthermore, the dried coating film was subjected to heat treatment and humidification treatment for 5 minutes in an environment at 60° C. and a humidity of 90%, to obtain a dichroic dye-containing layer having a thickness of 0.15 μm. Using a spin coater, an acrylic resin-based ultraviolet curable resin composition (SPC-920C ma...

Embodiment 2

[0105] For the non-adhesively treated surface of the stretched film with a retardation of 10500 nm used in Example 1, a roller wound with a rubbing cloth (MK0012 manufactured by Taenaka Pile Fabrics Co., Ltd.) was used along the direction relative to the stretched film. A measurement sample was produced in the same manner as in Example 1, except that the direction of the slow axis was 0°, and a friction treatment was further performed at a speed of 100 rpm and a load of 5 kgf. At this time, the angle with respect to the slow axis of a stretched film was measured with KOBRA-21ADH (made by Oji Scientific Instruments).

Embodiment 3

[0107] With respect to the non-adhesively treated surface of the stretched film having a retardation of 10500 nm used in Example 1, rubbing was carried out in a direction at 45° to the slow axis of the stretched film with a roller wound with a rubbing cloth. The treatment was performed in the same manner as in Example 2 except for that, and a measurement sample was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com