A Horizontal Speed Compensation Mechanism Driven by Eccentric Gears of Corn Seeder

A technology of eccentric gear and compensation mechanism, which is used in planter parts, sowing, agriculture, etc., can solve the problems of film picking, film scraping, low seeding qualification rate and high labor intensity, so as to reduce labor intensity, increase room for improvement, and improve The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

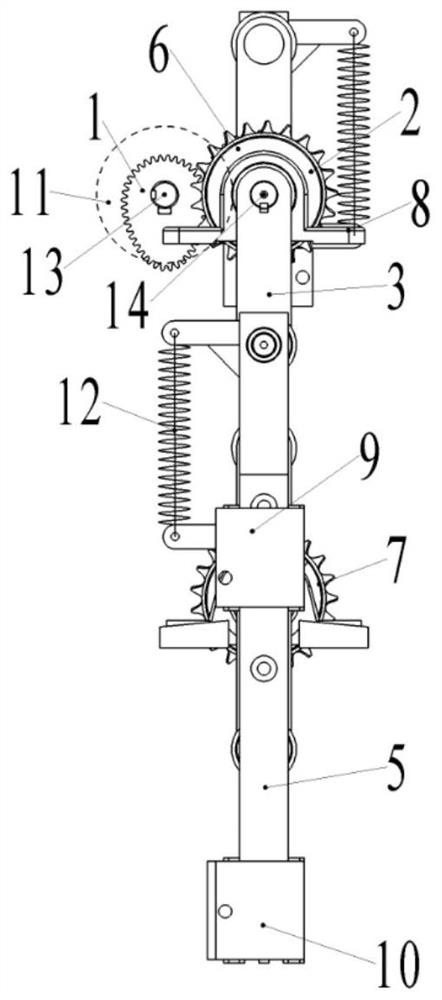

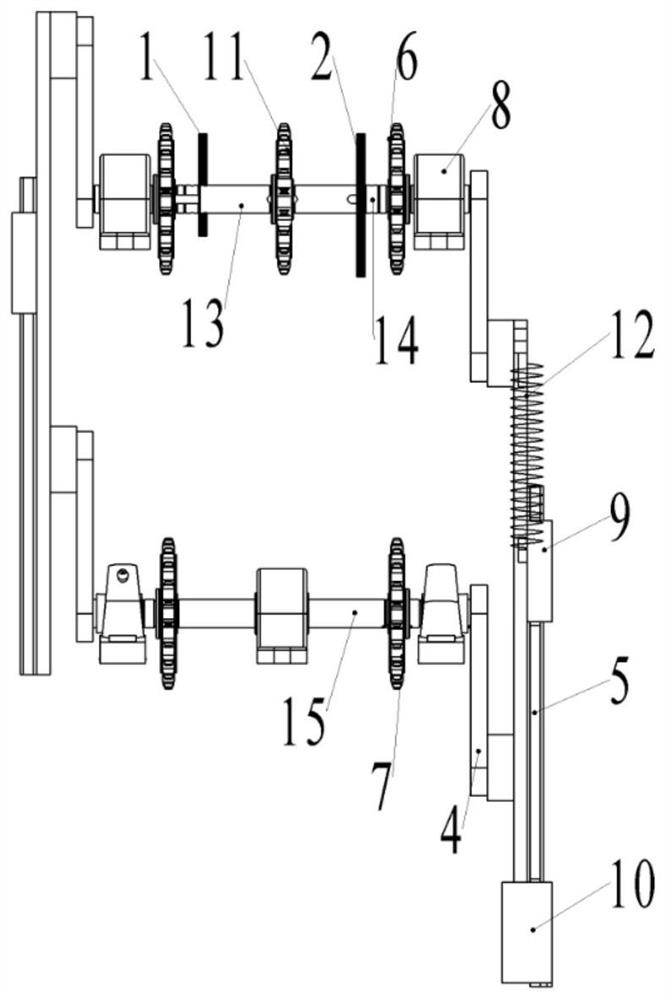

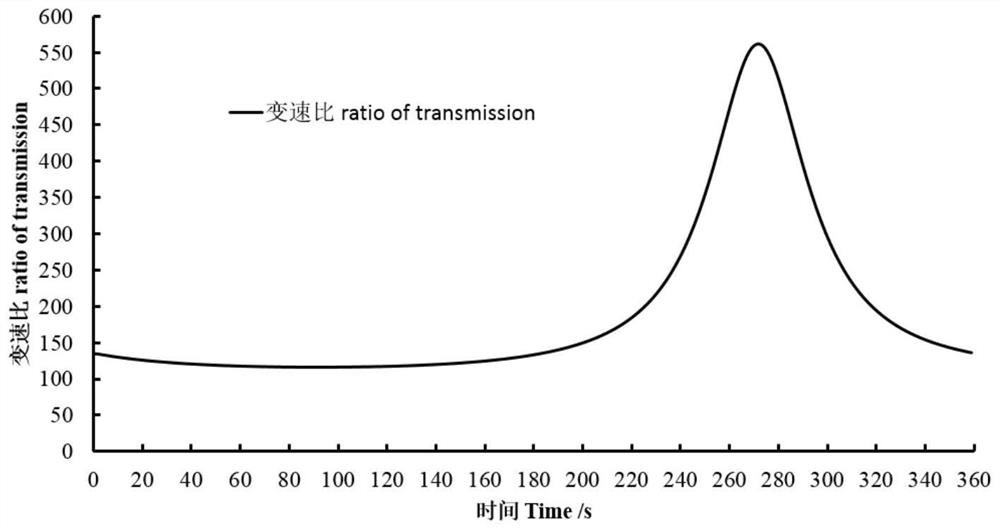

[0016] Such as Figures 1 to 4 As shown, the eccentric gear drive horizontal speed compensation mechanism of a kind of corn planter is characterized in that it includes a meshing active eccentric gear 1 and a driven eccentric gear 2, and the active eccentric gear 1 and the power input sprocket 11 pass through the power input shaft 13 is fixedly connected, the driven eccentric gear 2 and the driving crank 3 are fixedly connected through the driving crank shaft 14, the driving crank 3, the driven crank 4, the hole sowing rod 5 and the frame form a parallel four-bar mechanism through hinged connection, the hole sowing rod 5 and the first A slide block 9 and the second slide block 10 slide up and down to connect, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com