Hand-shredded dried tofu with strong juice absorption ability and preparation method thereof

A technology of dried tofu and hand-tearing, applied in the field of food processing, can solve the problems of short duration of aftertaste, less absorption of soup, and the chewing feeling needs to be further improved, so as to achieve the effect of lasting aftertaste, strong chewing feeling and dense pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Ingredients for making tofu include:

[0049] 12 parts of soybean protein powder, 9 parts of soybean oil, 62.38 parts of ice water, 18 parts of borneol, 0.26 parts of salt, 0.52 parts of sugar, 0.26 parts of monosodium glutamate, 0.19 parts of TG, 5 parts of tapioca modified starch.

[0050] Marinade recipes, including:

[0051] Stew: 2 parts fennel, 0.5 parts cinnamon, 2 parts star anise, 0.2 parts white buckle, 0.2 parts nutmeg, 0.3 parts hawthorn, 2 parts cinnamon, 0.2 parts tangerine peel, 0.3 parts licorice, 0.3 parts lemongrass, 0.2 parts pepper , 0.2 parts of grass fruit, 2 parts of pepper, 3 parts of table salt, 1 part of white sugar, 0.2 parts of monosodium glutamate, 0.3 parts of pickled pepper paste. Based on 1000mL water.

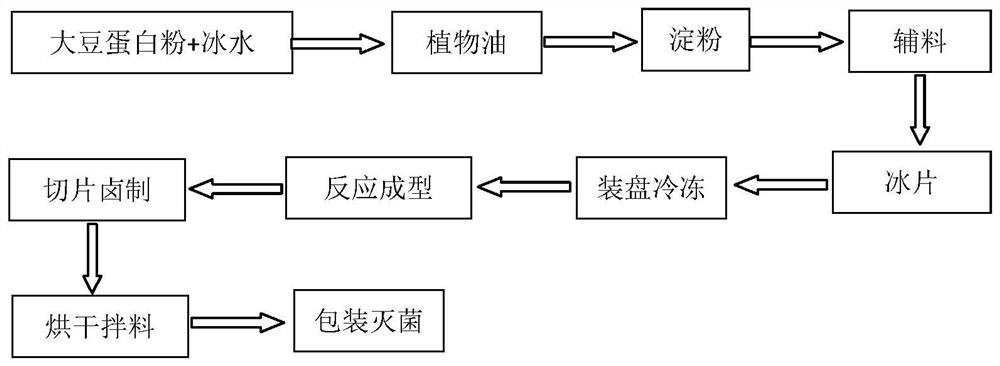

[0052] The preparation steps of shredded dried tofu with strong juice-absorbing ability include:

[0053] The first step is to prepare materials and accurately weigh ingredients;

[0054] The second step is hydration. Add soybean prot...

Embodiment 2

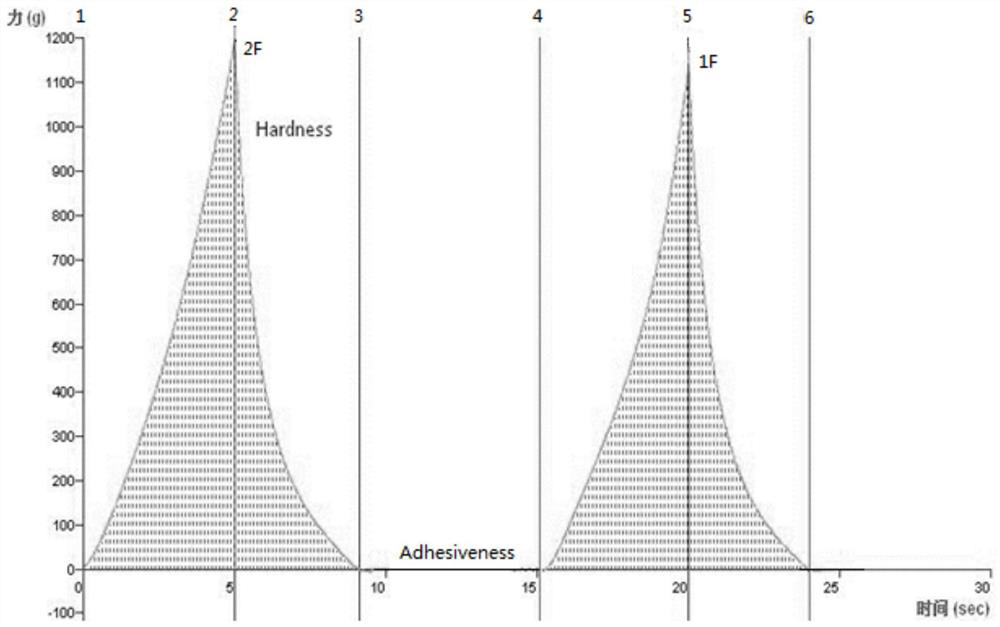

[0070] In Example 2, on the basis of Example 1, the added amount of ice flakes was reduced, and the effect of the added amount of ice on the adsorption amount of the product soup was verified.

[0071] Ingredients for making tofu include:

[0072] 12 parts of soybean protein powder, 9 parts of soybean oil, 65 parts of ice water, 13 parts of borneol, 0.26 parts of salt, 0.52 parts of sugar, 0.26 parts of monosodium glutamate, 0.19 parts of TG, 5 parts of tapioca modified starch.

[0073] The halogen material formula and preparation process are identical with embodiment 1.

Embodiment 3

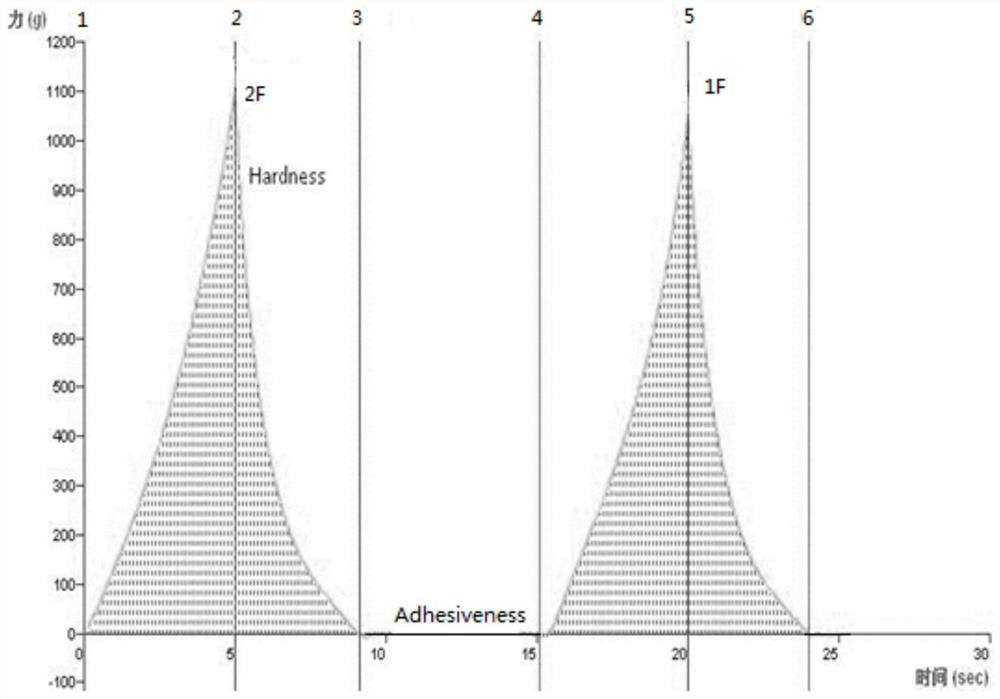

[0075] Embodiment 3 adds edible glue on the basis of embodiment 2, verifies the effect of edible glue in the product.

[0076] Ingredients for making tofu include:

[0077] 12 parts of soybean protein powder, 9 parts of soybean oil, 65 parts of ice water, 13 parts of borneol, 0.26 parts of salt, 0.52 parts of sugar, 0.26 parts of monosodium glutamate, 0.19 parts of TG, 5 parts of modified tapioca starch, and 0.2 parts of edible gum.

[0078] The halogen material formula and preparation process are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com