Field processing method of fresh pinellia ternata

A technology of producing area processing and Pinellia, applied in the field of toxic Chinese medicinal materials processing, can solve the problems of enhancing the antitussive and expectorant efficacy of Pinellia, residual toxic components, etc., to ensure the safety of medicinal use, reduce the crystal content, and improve the medicinal use. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for producing fresh pinellia, which includes the following steps:

[0018] ① Take fresh pinellia, peel and wash, cut into 5mm thick slices, first pierce small holes evenly on the surface of the pinellia slices, the number of small holes is 4, and the diameter of the small holes is 1.5mm;

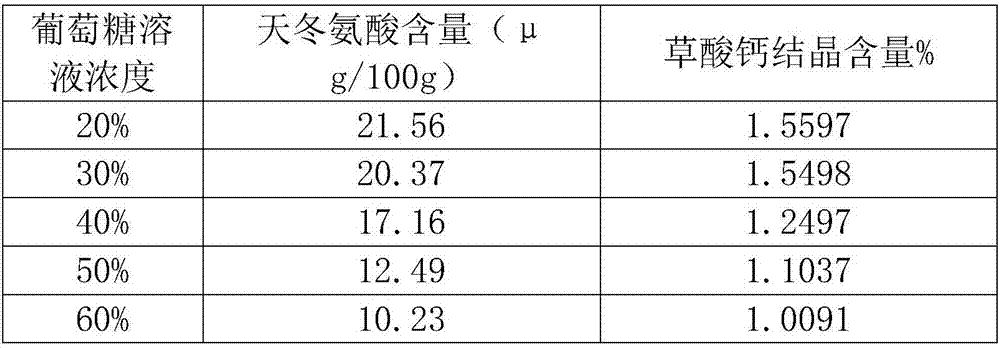

[0019] ②. Fumigate the Pinellia flakes treated in step ① with water vapor at 120°C for 30 seconds, then immerse the Pinellia flakes in a glucose solution with a concentration of 40% for 40 minutes, take out the Pinellia flakes for infrared drying for 5 minutes, and filter the glucose solution for later use;

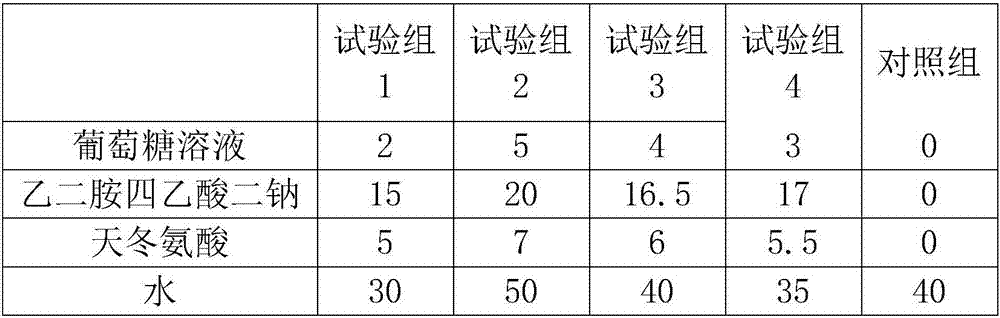

[0020] ③. According to parts by weight, take 2 parts of glucose solution soaked in Pinellia flakes in step ②, 15 parts of disodium edetate, 5 parts of aspartic acid, and 30 parts of water, mix, and stir until the solution is transparent to make penetration liquid;

[0021] ④ Put the penetrating liquid in a sprayer, spray the dried Pinellia flakes evenly, spray until the Pinellia...

Embodiment 2

[0023] A method for producing fresh pinellia, which includes the following steps:

[0024] ① Take fresh pinellia, peel and wash, and cut into 6mm thick slices. First, evenly pierce small holes on the surface of the pinellia slices. The number of small holes is 5 and the diameter of the small holes is 2mm;

[0025] ②. Fumigate the Pinellia flakes treated in step ① with water vapor at 150°C for 60 seconds, then immerse the Pinellia flakes in a glucose solution with a concentration of 40% for 60 minutes, take out the Pinellia flakes for infrared drying for 10 minutes, and filter the glucose solution for later use;

[0026] ③. According to the weight, take 5 parts of the glucose solution soaked in Pinellia flakes in step ②, 20 parts of disodium edetate, 7 parts of aspartic acid, and 50 parts of water, mix, and stir until the solution is transparent to make penetration liquid;

[0027] ④ Put the penetrating liquid in a sprayer, spray the dried Pinellia flakes evenly, spray until the Pinell...

Embodiment 3

[0029] A method for producing fresh pinellia, which includes the following steps:

[0030] ① Take fresh pinellia, peel and wash, and cut into 5.5mm thick slices. First, evenly pierce small holes on the surface of the pinellia slices. The number of small holes is 4 and the diameter of the small holes is 1.8mm;

[0031] ②. Fumigate the Pinellia flakes treated in step ① with steam at 140°C for 45s, then immerse the Pinellia flakes in a glucose solution with a concentration of 40%, soak for 50 minutes, take out the Pinellia flakes and dry for 8 minutes by infrared, and filter the glucose solution for later use;

[0032] ③. According to parts by weight, take 4 parts of glucose solution soaked in Pinellia flakes in step ②, 16.5 parts of disodium edetate, 6 parts of aspartic acid, and 40 parts of water and mix, stir until the solution is transparent to make penetration liquid;

[0033] ④ Put the penetrating liquid in a sprayer, spray the dried Pinellia flakes evenly, spray until the Pinellia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com