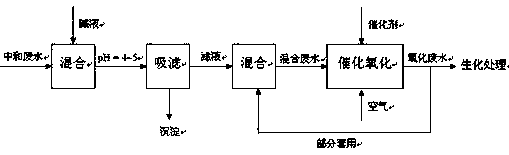

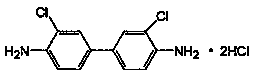

A catalytic oxidation treatment method for 3,3'-dichlorobenzidine hydrochloride neutralized wastewater

A technology of dichlorobenzidine hydrochloride and catalytic oxidation, which is applied in oxidation water/sewage treatment, natural water treatment, chemical instruments and methods, etc. Simple process, good industrialization prospects, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add the neutralization wastewater to the four-necked flask, turn on the stirring, use a dropping funnel to drop the lye into the neutralization wastewater, and measure the pH value after stirring. When the pH reaches 4, the dripping is stopped, the stirring is maintained for 15 minutes, and then transferred to a suction filter flask for suction filtration, and the precipitate is filtered to obtain a clear filtrate.

[0021] An activated carbon catalyst is filled in the catalytic oxidation reactor, the catalyst filling volume is 1 / 2 of the reactor volume, and tap water is added until the liquid surface is flush with the catalyst surface. The filtrate and tap water are mixed in a ratio of 1:3 and then continuously pumped into the top of the catalytic oxidation reactor, and air is continuously introduced from the bottom of the reactor. The volume flow rate (GHSV) of air passing through the catalyst per unit time is 40 h -1 , The ratio of mixed wastewater flow rate to air flow...

Embodiment 2

[0023] Add the neutralization wastewater to the four-necked flask, turn on the stirring, add the spent alkali to the neutralization wastewater dropwise with a dropping funnel, and measure the pH value after stirring. When the pH reaches 5, the dripping is stopped, the stirring is maintained for 10 minutes, and then transferred to a suction filter bottle for suction filtration, and the precipitate is filtered to obtain a clear filtrate.

[0024] The catalytic oxidation reactor is filled with activated carbon catalyst, the catalyst filling volume is 1 / 2 of the reactor volume, and distilled water is added until the liquid surface is level with the catalyst surface. The filtrate and distilled water are mixed in a ratio of 1:2 and then continuously pumped into the top of the catalytic oxidation reactor, and air is continuously introduced from the bottom of the reactor. The volume flow rate (GHSV) of the air passing through the catalyst per unit time is 20 h -1 , The ratio of mixed was...

Embodiment 3

[0026] Add the neutralization wastewater into the four-necked flask, turn on the stirring, add the spent alkali to the neutralization wastewater dropwise with a dropping funnel, and measure the pH value after stirring. When the pH reaches 4, the dripping is stopped, the stirring is maintained for 10 min, and then transferred to a suction filter bottle for suction filtration, and the precipitate is filtered to obtain a clear filtrate.

[0027] The catalytic oxidation reactor is filled with activated carbon catalyst, the catalyst filling volume is 2 / 3 of the reactor volume, and deionized water is added until the liquid surface is flush with the catalyst surface. The filtrate was mixed with deionized water in a ratio of 1:3 and then continuously pumped into the top of the catalytic oxidation reactor, and air was continuously introduced from the bottom of the reactor. The volume flow rate (GHSV) of air passing through the catalyst per unit time is 25 h -1 , The ratio of mixed wastewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com