Stress-whitening resistant styrene-based resin and preparation method thereof

A styrene-based resin and stress-resistant technology, which is applied in the field of stress-whitening-resistant styrene-based resin and its preparation, can solve problems such as the general effect of internal stress relief, and achieve the prevention of stress-whitening phenomenon, stable product quality, and smooth process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) 85 parts of ABS 8434 resin, 15 parts of superfine calcium carbonate (6000 mesh), 0.3 part of light and heat stabilizer (antioxidant 1076: antioxidant 168=1:2, mass ratio) and 0.1 part of lubricant Stearic acid amide (SR) is mixed evenly by high-speed stirring;

[0042] (2) sending the above-mentioned mixture into a twin-screw extruder to extrude and granulate to obtain a styrene-based resin;

[0043] In the described step (2), the screw temperature of the twin-screw extruder is 400r / min.

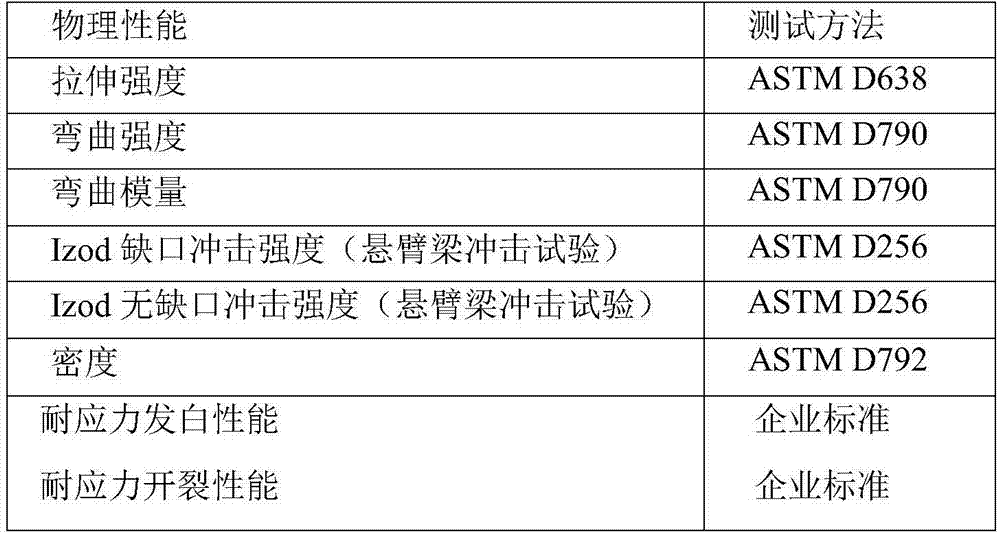

[0044] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 2

[0046] (1) Mix 98 parts of ABS8434 and ASA PW-957 resin mixture (ABS8434:ASA PW-957=2:1, mass ratio), 2 parts of superfine calcium carbonate (7000 mesh), 0.6 parts of light and heat stabilizer (DLTP : DBTL=1:1, mass ratio) and 0.5 parts of lubricant silicone oil are mixed evenly by high-speed stirring;

[0047] (2) sending the above-mentioned mixture into a twin-screw extruder to extrude and granulate to obtain a styrene-based resin;

[0048] In the described step (2), the screw temperature of the twin-screw extruder is 500r / min.

[0049] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 3

[0051] (1) 90 parts of ASA PW-957 resin, 10 parts of superfine calcium carbonate (6000 mesh), 0.1 part of light and heat stabilizer (DLTP: 2,6-tertiary butyl-4-methylphenol=2:1 , mass ratio) and 1 part of lubricant EBS are mixed evenly by high-speed stirring;

[0052] (2) sending the above-mentioned mixture into a twin-screw extruder to extrude and granulate to obtain a styrene-based resin;

[0053] In the described step (2), the screw temperature of the twin-screw extruder is 300r / min.

[0054] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com