Modified asphalt having self-repairing capability and preparation method

A modified asphalt and self-repairing technology, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of cumbersome, difficult large-scale maintenance of asphalt pavement, and high maintenance costs, so as to save resources and solve difficult large-scale maintenance. , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

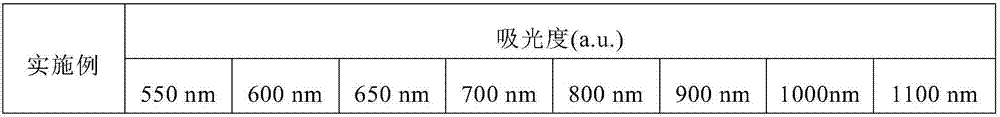

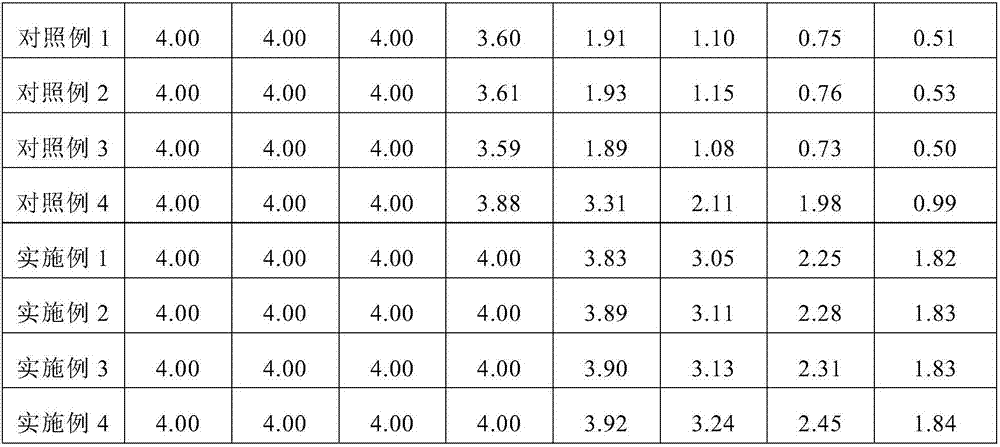

Embodiment 1

[0047]Melt 70# asphalt to 130°C, add 4.8wt% SBR, 5.0wt% flake graphite, and 30wt% steel wool accounting for the mass of 70# asphalt, keep a constant temperature of 130°C, and use a high-speed shearer to cut at a speed of 4000rpm for 60min; Then add PPA accounting for 1.5wt% of the 70# asphalt mass, heat to 160°C and keep a constant temperature, use a high-speed shearing machine to cut at a speed of 4000rpm for 40min, and cool to room temperature under natural conditions to obtain modified asphalt;

Embodiment 2

[0049] Melt 70# asphalt to 130°C, add 4.8wt% SBR, 5.0wt% nano-graphite flakes, and 30wt% steel wool to the mass of 70# asphalt, keep the constant temperature at 130°C, and use a high-speed shearing machine to cut at a speed of 4000rpm for 60min Then add PPA accounting for 1.5wt% of the 70# bitumen mass, heat to 160°C and keep a constant temperature, use a high-speed shearing machine to cut for 40min at a speed of 4000rpm, and cool to room temperature under natural conditions to obtain modified asphalt;

Embodiment 3

[0051] Melt 70# asphalt to 130°C, add 4.8wt% SBR, 5.0wt% nano-cesium tungsten bronze powder, and 30wt% steel wool to the mass of 70# asphalt, keep the constant temperature at 130°C, and use a high-speed shearing machine to cut at a speed of 4000rpm Cut for 60 minutes; then add PPA accounting for 1.5wt% of the 70# asphalt mass, heat to 160°C and keep a constant temperature, cut with a high-speed shear at a speed of 4000rpm for 40 minutes, and cool to room temperature under natural conditions to obtain modified asphalt;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com