Inverse installation and construction method of indoor stage steel structure in theater

A construction method and technology of steel structure, applied in the direction of building structure, construction material processing, construction, etc., can solve the problems of high safety management risk, waste of materials, cumbersome construction, etc., to improve economic benefits, reduce costs, and avoid residual effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

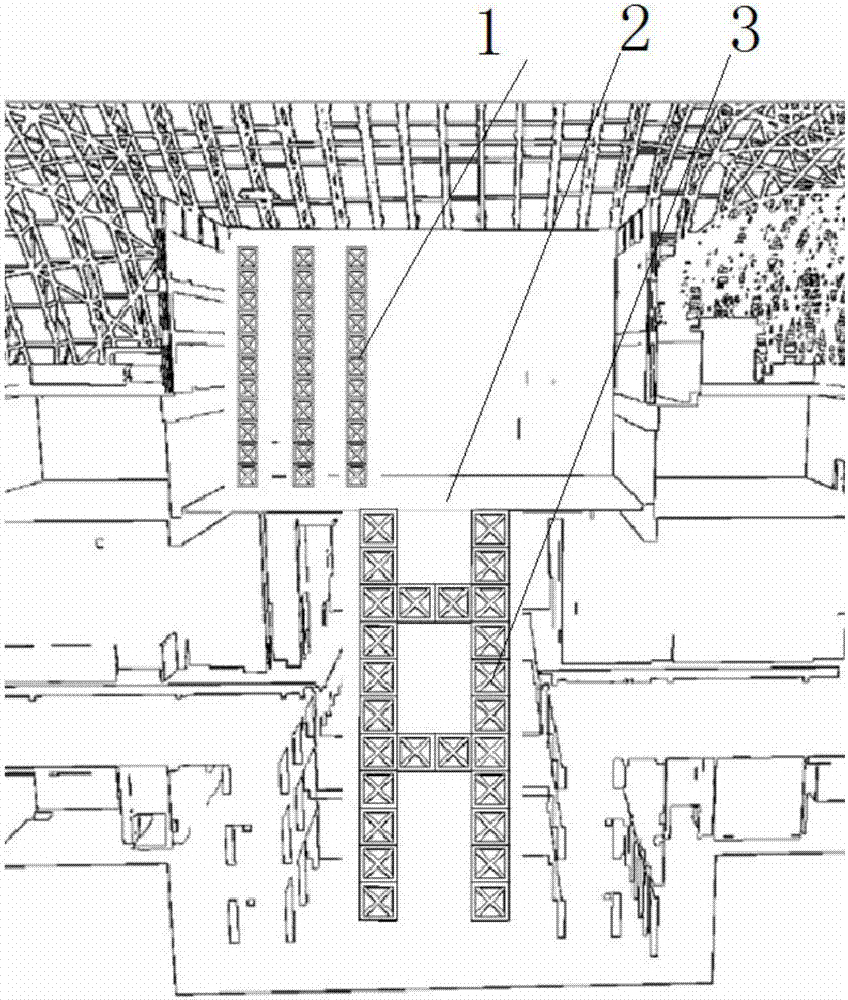

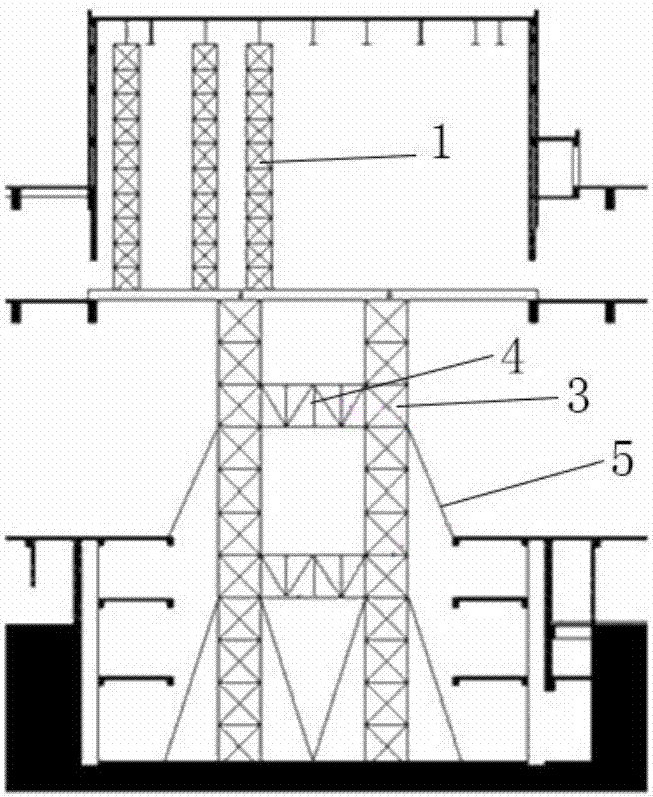

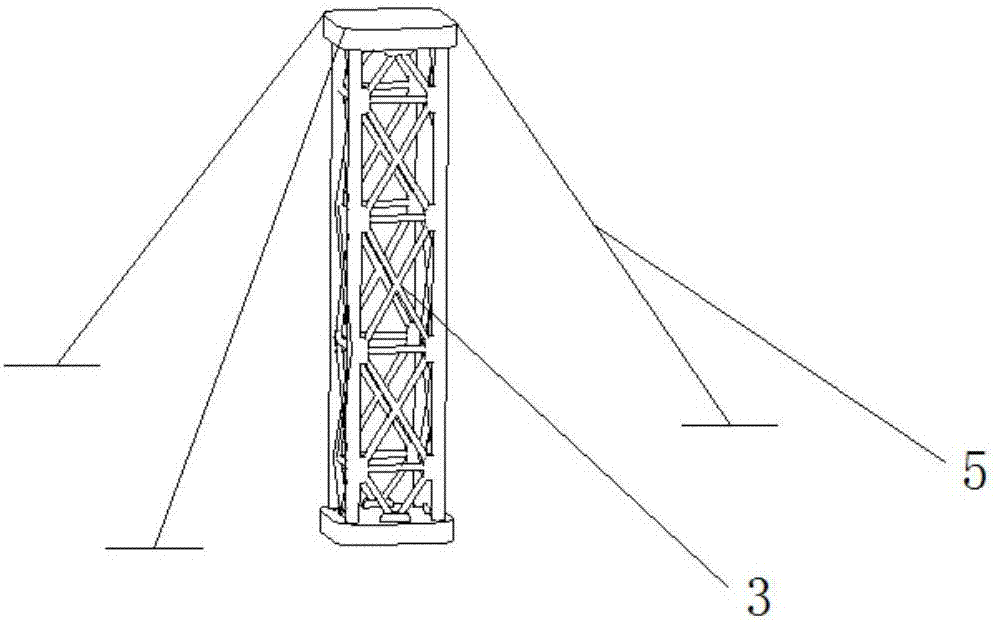

[0059] Embodiment 1: A method of reverse installation and construction of the steel structure of the indoor stage of a grand theater. The steel beams on the roof layer of the stage of the grand theater are reversely constructed and installed, and the support system is erected and installed from bottom to top, including the following steps:

[0060] (1) BIM simulation analysis

[0061] Carry out BIM modeling for the civil engineering and indoor steel structure of the grand theater, and simulate and stress analysis for the installation of steel beams on the stage roof and the erection support system for its construction;

[0062] After the simulation analysis, enter the construction stage. Before the construction, it must be ensured that the steel components have been submitted for inspection and passed, and the materials, components, and machinery required for construction have all entered the site;

[0063] (2) Measurement preparation

[0064] Construction survey to determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com