Impeller-guiding speed-changing swirling-flow anti-wax device

A technology of impeller and diversion impeller, which is applied in the direction of cleaning equipment, wellbore/well components, earthwork drilling and mining, etc., which can solve problems such as wax deposition, achieve the effects of simplifying the installation structure, increasing flow pressure, and delaying crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

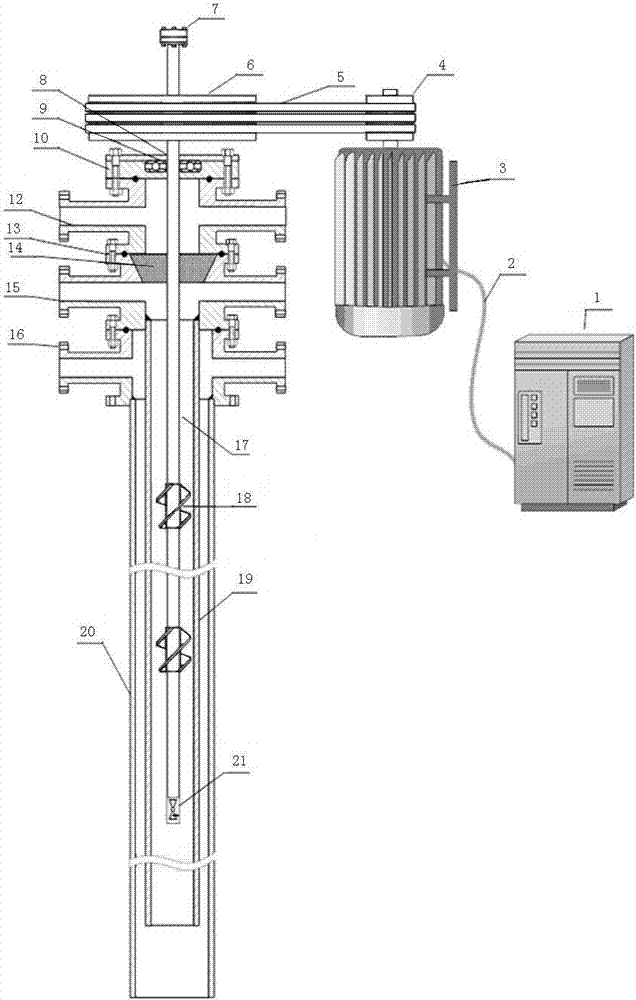

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] Such as figure 1 As shown, this impeller diversion type variable speed swirl wax prevention device includes a motor, a pulley assembly, and a hollow rod 17. The motor is connected to the hollow rod 17 through the pulley assembly, and the hollow rod 17 is suspended at the wellhead by the upper cross assembly. The rod 17 extends downwards into the oil pipe 19, the flange joint 7 is installed on the upper end of the hollow rod 17, the check valve 21 is installed on the lower end of the hollow rod 17, and the guide vane 18 is set at the position where the hollow rod 17 extends into the oil pipe 19 to guide the flow. The impeller 18 has blades, and when the guide impeller 18 rotates with the hollow rod 17, the guide impeller 18 will pressurize and increase the speed of the liquid production, forming a spiral flow of liquid, scouring and scraping the wax on the wall, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com