Device for testing soft-melting and dropping characteristics of ferruginous burden of blast furnace and method

A test device, iron furnace technology, applied in the direction of measuring device, flow characteristics, analysis materials, etc., can solve the problems of poor test reproducibility, affecting the reliability and precision of results, etc., and achieve the effect of improving accuracy and reliability

Pending Publication Date: 2018-01-05

UNIV OF SCI & TECH LIAONING

View PDF13 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In the above method of measuring the refractory dripping characteristics of iron-containing charge, the amount of sample is small, and the initial mass of iron-containing charge is about 500g. Due to its high density, the iron ore sample of 10-12.5mm is only 3-4 blocks can be placed, which leads to poor reproducibility of the test; and the reducing gas used in the test process is at room temperature, which is inconsistent with the actual production situation of the blast furnace. It can be known from the principle of thermodynamics that high temperature affects the reaction efficiency and progress of the reduction reaction Both have a great influence, and the use of normal temperature reducing gas in the droplet test affects the reliability and accuracy of the results

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0042] In order to make the purpose, technical solution and advantages of the patent of the present invention clearer, the patent of the present invention will be further described in detail below in conjunction with the examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

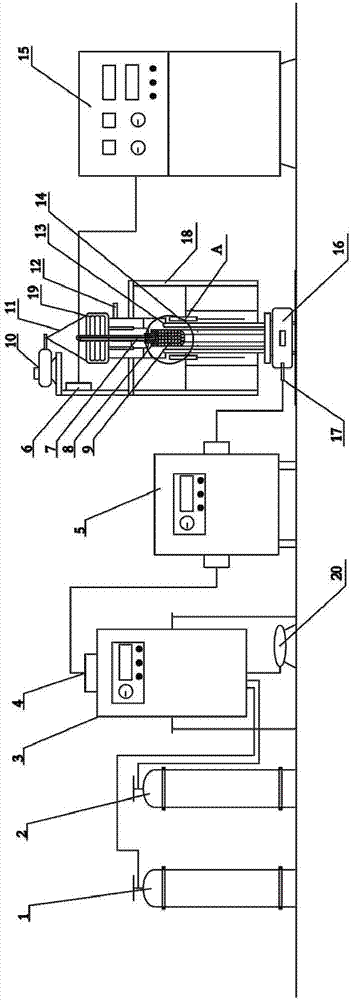

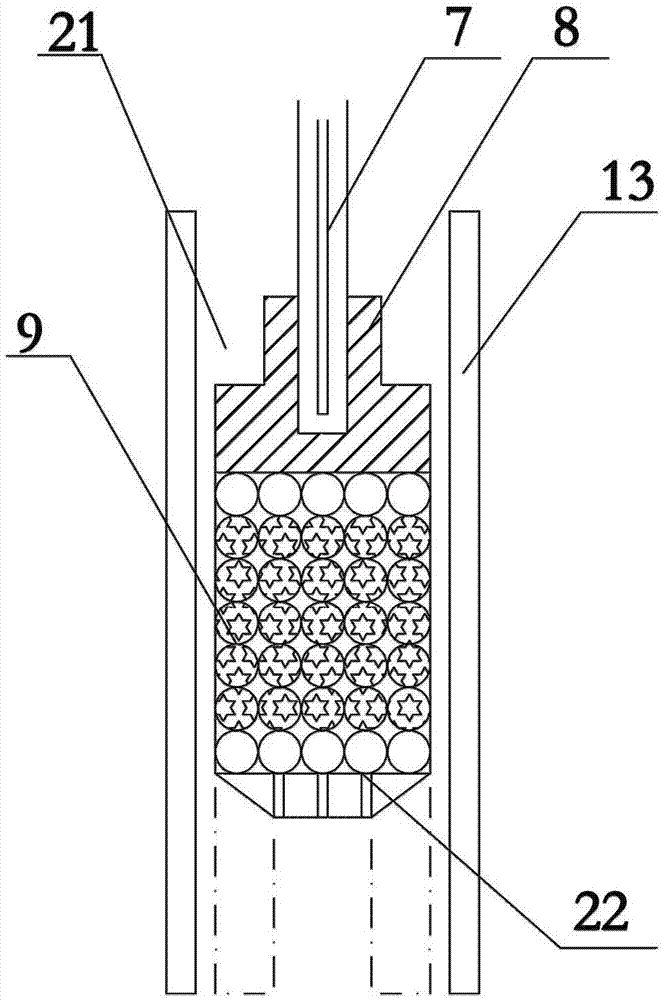

The invention relates to a device for testing soft-melting and dropping characteristics of ferruginous burden of a blast furnace and a method. The device comprises a melting and dropping furnace, a heating device, a graphite pressure lever, a thermocouple, a sampling box, reductive gas and an automatic control device and is characterized by further comprising a supporting framework, a lifting mechanism, a load, a displacement sensor and a gas supplying system. The graphite pressure lever is a piston type graphite pressure lever, one end of the load is fixedly connected with the piston type graphite pressure lever, the other end of the load is fixedly connected with a hoisting steel wire rope, and a lifting motor of the lifting mechanism, the gas supplying system and the heating device areall electrically connected with the automatic control device. The device and the method have the advantages that through carrying out testing by a 2kg-grade large-sized melting and dropping furnace and assisting the melting and dropping furnace with the heated reductive gas, the soft-melting and dropping characteristics of iron ore can be more accurately tested, and a reference foundation is provided for actual raw material regulation, technical research and the like of blast furnace production. The accuracy and reliability of test results can be greatly improved.

Description

technical field [0001] The invention belongs to the technical field of blast furnace smelting, and in particular relates to a testing device and method for the reflow dripping characteristics of blast furnace iron-containing charge. Background technique [0002] After the iron-containing charge (including sinter, pellets and lump ore) used in the blast furnace enters the furnace, it is gradually softened and melted during the descent process with high temperature, high pressure and chemical reaction. As the temperature rises further, the molten iron-containing charge Transform into slag and molten iron, achieve free flow and accumulate into droplets, dripping from the reflow belt into the furnace hearth. The position, thickness and shape of the soft melting zone determine the distribution of gas in the blast furnace, thereby affecting the smelting process of the blast furnace. Therefore, the good metallurgical properties of the iron-containing charge are an important guarant...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N11/00G01N25/04

Inventor 湛文龙邸航孙崇余盈昌徐泽宇庞清海张军红何志军

Owner UNIV OF SCI & TECH LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com