Self-extraction method of cement calciner temperature based on bfcm-iwm fuzzy rules

A temperature control method and technology of cement calcining furnace, which are applied in the direction of using electric mode for temperature control, etc., can solve the problems of low production efficiency, high energy consumption, inaccurate control, etc., and achieve the effect of good applicability and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

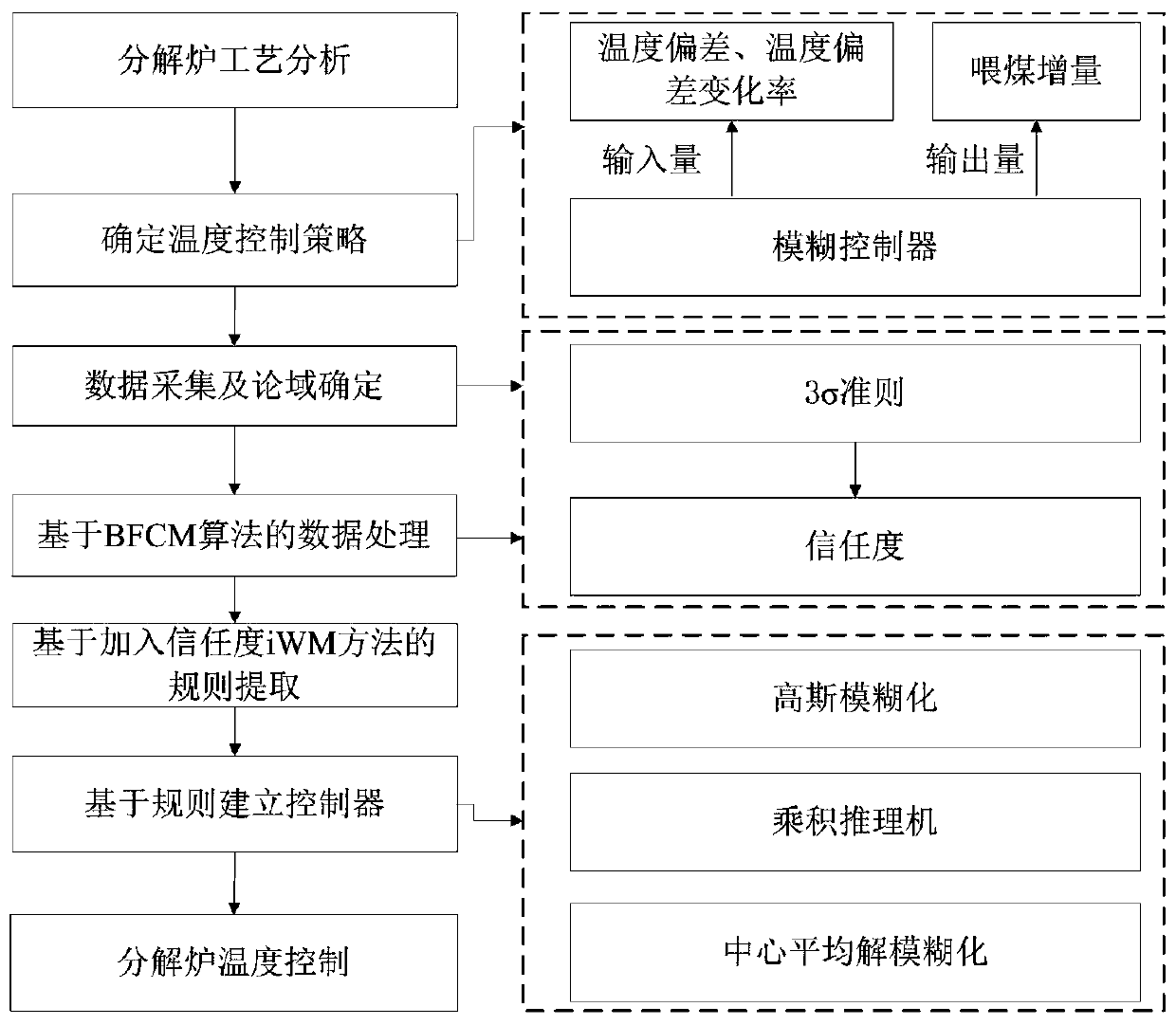

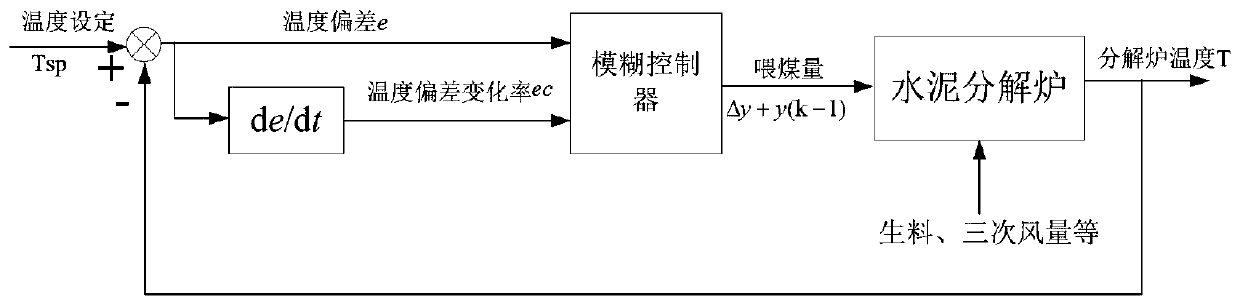

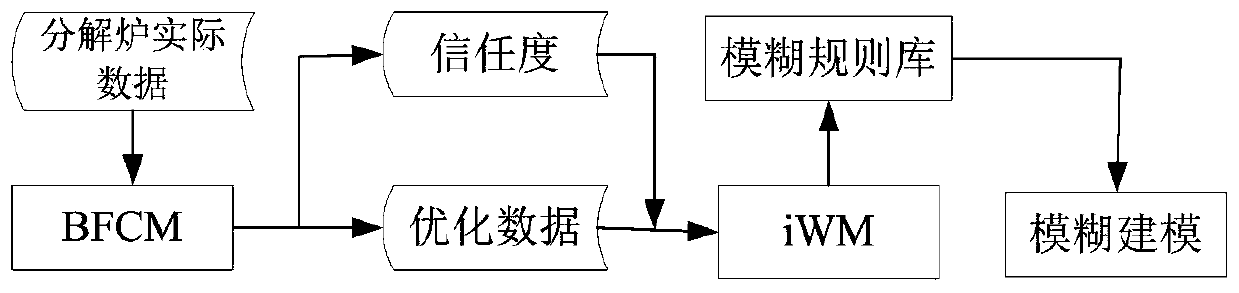

[0066] Example 1: The present invention is based on the BFCM-iWM fuzzy rule self-extraction cement decomposition furnace temperature control method, which is applied in a cement plant to control the outlet temperature of the cement decomposition furnace. The implementation process is as follows figure 1 shown. Firstly, according to the process flow analysis of the cement calciner, the variables that affect the temperature and the temperature control strategy are clarified; according to the conditions of the coal feed change of the calciner and the 3σ criterion, the collected original data is eliminated and selected to obtain the sample data, and the BFCM algorithm is used Clustering sample data is processed, and the concept of trust degree is introduced; on this basis, the iWM method is used to extract rules from the data, and a fuzzy controller is established according to the extracted rules; finally, the controller is applied to the temperature control of the calciner to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com