Reciprocating motor and reciprocating compressor having the same

A reciprocating, reciprocating motion technology, applied in the direction of machines/engines, liquid variable capacity machinery, electromechanical devices, etc., can solve the problems of increased power consumption, reduced motor efficiency, increased air gap, etc., to reduce friction loss and Effects of noise, reduced number of parts, and increased spring rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

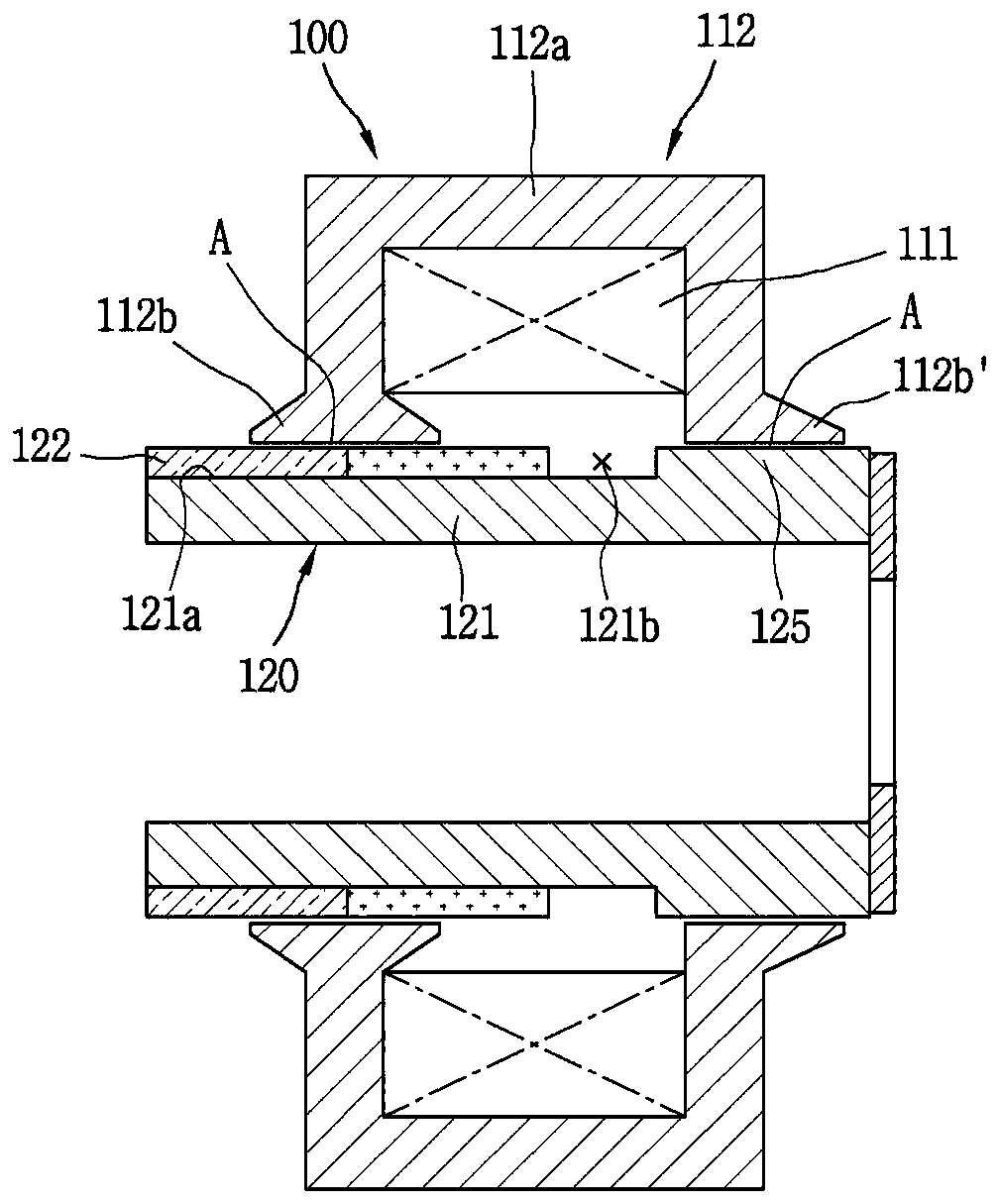

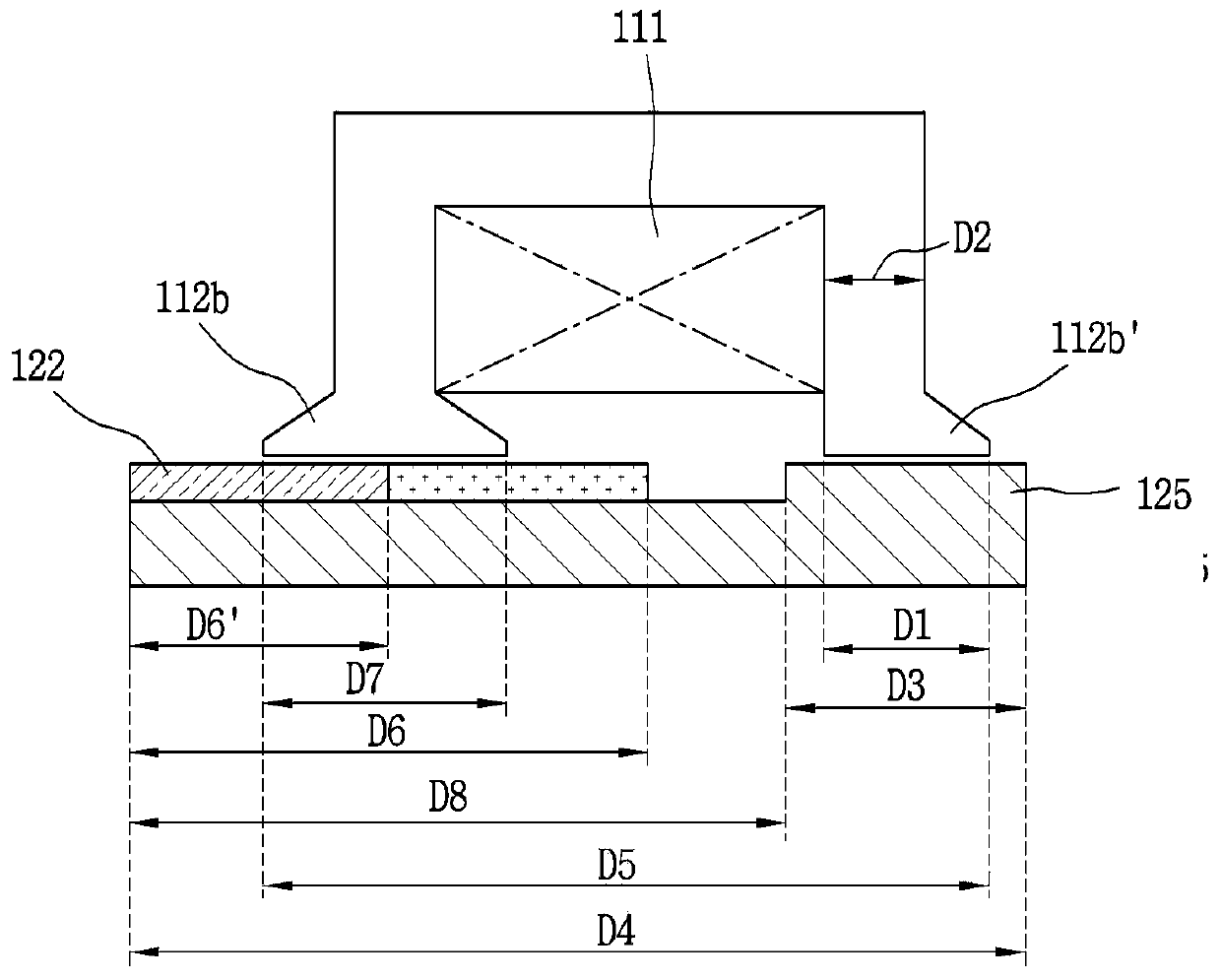

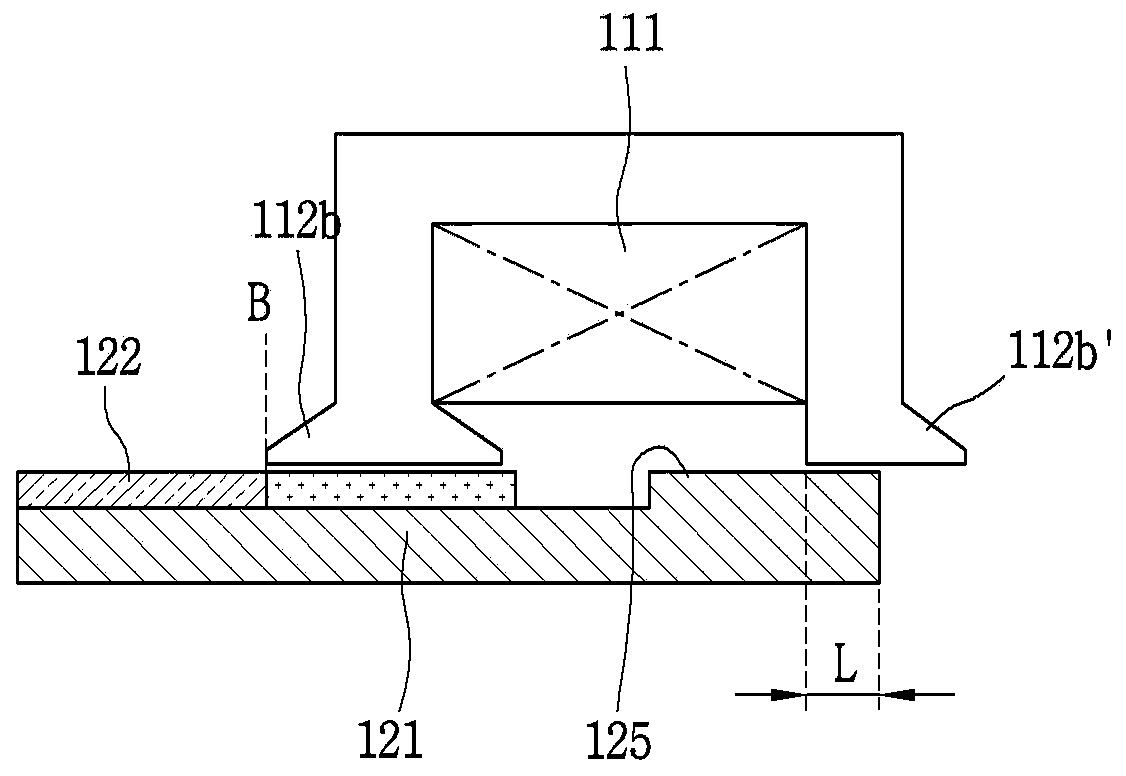

[0063] Hereinafter, a reciprocating motor and a reciprocating compressor including the reciprocating motor according to the present invention will be described in detail based on an embodiment shown in the drawings.

[0064] The reciprocating motor of the present embodiment performs reciprocating motion using a centering force in a reciprocating direction generated between a stator provided with a magnetic coil and a magnet. The central force in the reciprocating direction refers to the force stored in the direction where the magnetic energy (magnetic potential energy, reluctance) is low when the magnet moves in the magnetic field, and this force forms a magnetic spring.

[0065] Therefore, in this embodiment, when the magnet reciprocates using the magnetic force based on the magnetic coil, the magnet accumulates a force to return to the direction of the air gap due to the magnetic spring, and the rotor including the magnet is driven by the force accumulated in the magnetic spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com